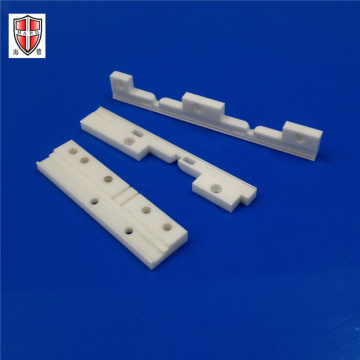

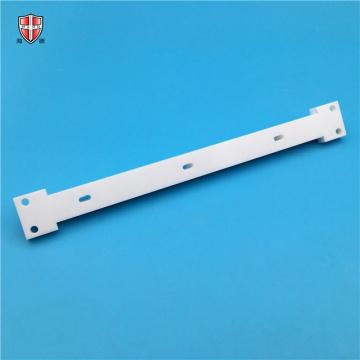

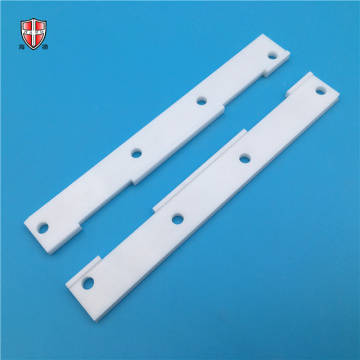

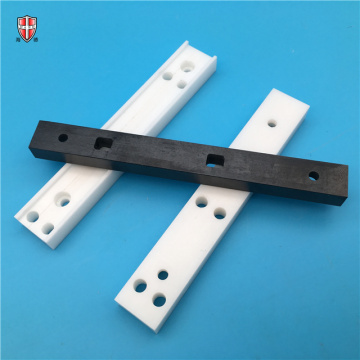

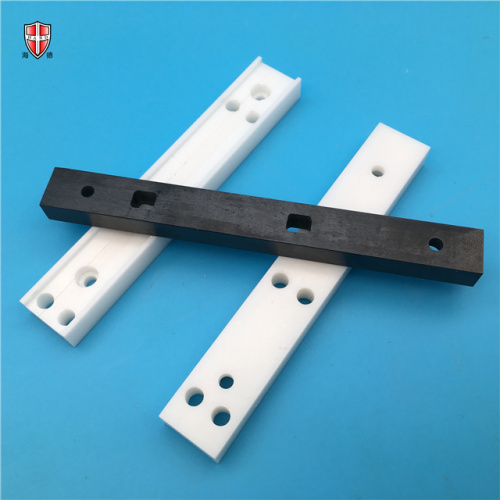

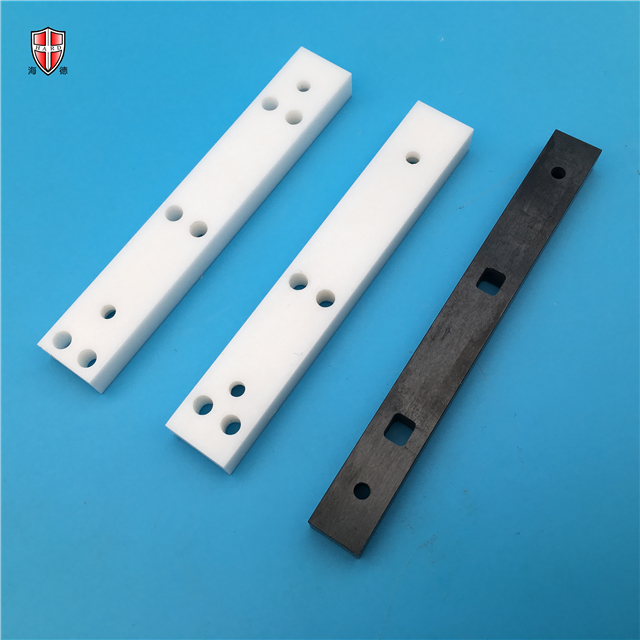

isostatic pressure sintered zirconium oxide ceramic bars

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

isostatic pressure sintered zirconium oxide ceramic bars

Reputation depends on quality, quality comes from Hard!

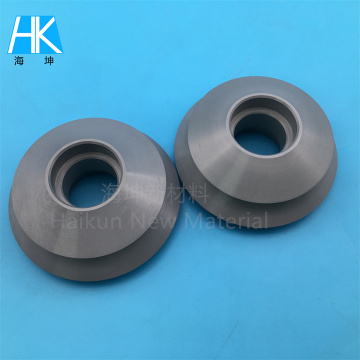

Zirconia Ceramics:

The modified varieties of zirconia polyethylene mainly include chlorinated polyethylene, chlorosulfonated polyethylene, cross-linked polyethylene and blended modified varieties Stainless Steel Plunger.

Chlorinated polyethylene: a random chloride obtained by partially replacing hydrogen atoms in polyethylene with chlorine. Chlorination is carried out under the initiation of light or peroxide, and is mainly produced by aqueous suspension method in industry. Due to the differences in the molecular weight and distribution of the raw material polyethylene, the degree of branching, the degree of chlorination after chlorination, the distribution of chlorine atoms and the residual crystallinity, chlorinated polyethylene can be obtained from rubber-like to hard plastic-like. The main purpose is to be used as a modifier of polyvinyl chloride to improve the Stainless Steel Plunger impact resistance of polyvinyl chloride. Chlorinated polyethylene itself can also be used as electrical insulation material and ground material.

Chlorosulfonated polyethylene: When polyethylene reacts with chlorine containing sulfur dioxide, part of the hydrogen atoms in the molecule are replaced by chlorine and a small amount of sulfonyl chloride groups to obtain chlorosulfonated polyethylene. The main industrial manufacturing method is the suspension method. Chlorosulfonated polyethylene is resistant to ozone, chemical corrosion, oil, heat, light, abrasion and tensile strength. It is an elastomer with good comprehensive performance and can be used to make food contact equipment parts.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords