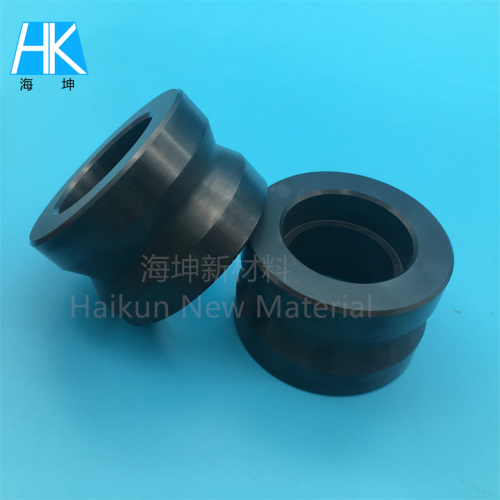

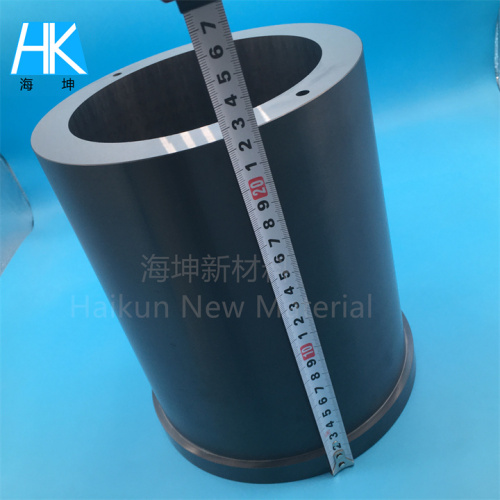

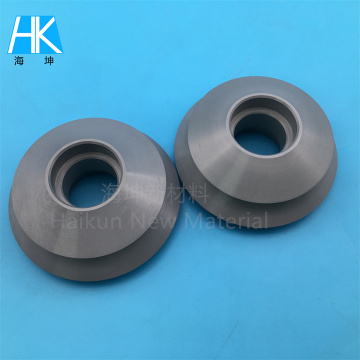

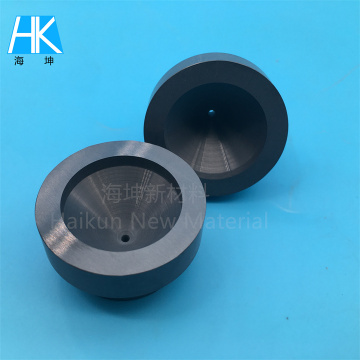

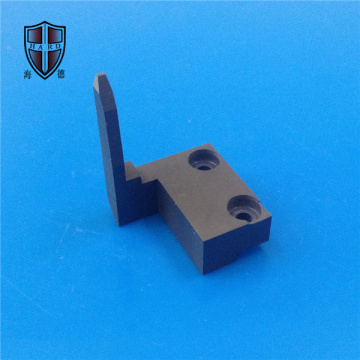

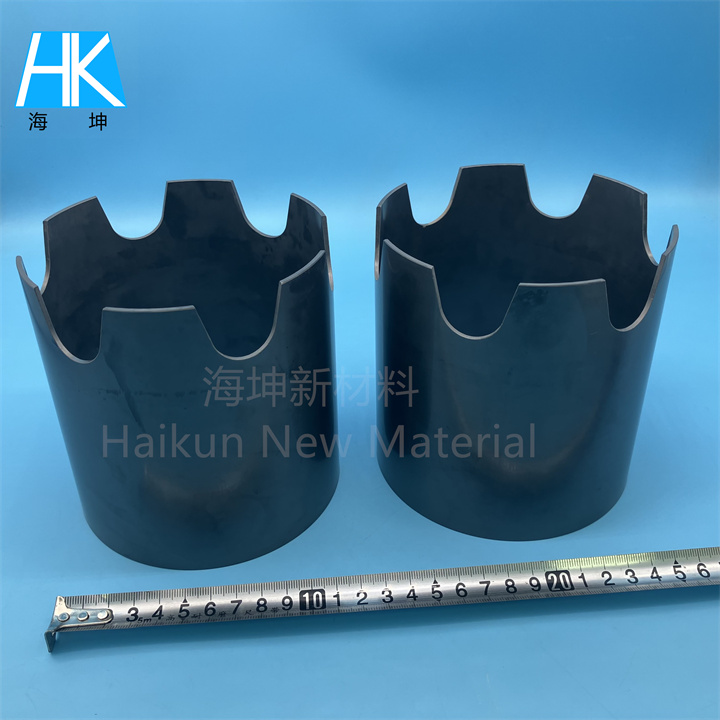

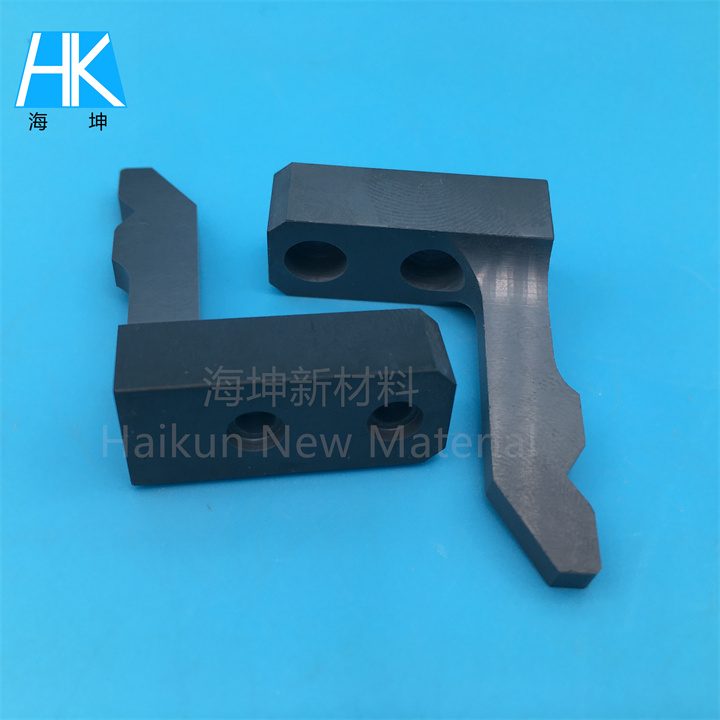

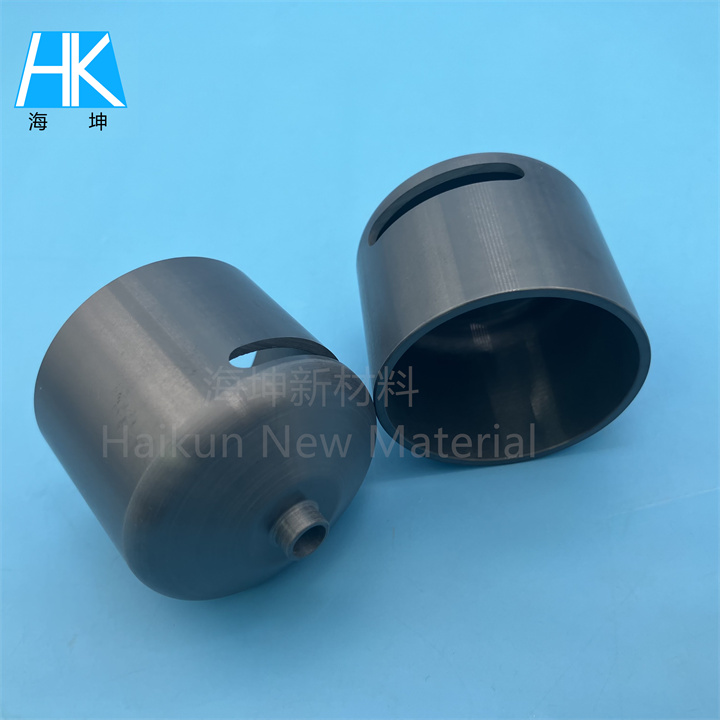

Silicon Nitride Ceramic Custom Parts Machining

-

$3.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Guangzhou, Shenzhen, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,DDU,Express Delivery,CPT,EXW,CIF,DDP |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Guangzhou,Shenzhen,Dongguan |

Silicon nitride ceramic is an advanced material used in high-temperature, high-stress applications due to its unique properties such as high strength, good wear resistance, and excellent thermal stability. Its applications range from aerospace components to medical implants, and from industrial machinery parts to precision tools. When it comes to machining custom parts from silicon nitride, there are several factors to consider:

1. **Material Properties**

- **High Strength**: Silicon nitride is one of the hardest materials known, making it very difficult to machine.

- **High Temperature Resistance**: It can withstand high temperatures without losing its mechanical properties, which is crucial for applications like gas turbines or high-temperature furnaces.

- **Chemical Stability**: It is resistant to many chemicals, enhancing its durability in corrosive environments.

2. **Machining Challenges**

- **Hardness**: The hardness of silicon nitride requires the use of specialized tools and techniques that can cut through the material without excessive heat generation, which can lead to tool wear and thermal damage.

- **Heat Generation**: Machining generates significant heat, which must be managed to prevent thermal cracking or warping of the part.

- **Tool Wear**: Specialized high-speed steel or diamond tools are often used, which can be expensive and require frequent replacement.

3. **Machining Techniques**

- **High-Speed Milling**: This is a common technique where the workpiece is held stationary while a rotating tool cuts into it. Special attention is given to tool geometry and cutting parameters to manage heat and tool wear.

- **Laser Cutting**: For intricate shapes or precise cuts, laser technology can be used. However, this process is typically more expensive and may not be suitable for all geometries.

- **Waterjet Cutting**: This non-contact method uses a high-pressure stream of water to cut through the material. It's effective but may not achieve the same surface finish as other methods.

4. **Post-Machining Processes**

- **Heat Treatment**: Silicon nitride often requires post-machining heat treatments to optimize its properties, such as increasing its strength or improving its microstructure.

- **Surface Finishing**: To achieve the desired surface finish and enhance performance, additional processes like grinding, honing, or polishing might be necessary.

5. **Quality Control**

- **Inspection**: Rigorous inspection methods are required to ensure the parts meet the dimensional and quality standards demanded by various industries.

- **Material Characterization**: Testing the machined parts for their mechanical properties, chemical composition, and structural integrity is crucial to confirm they meet the specifications.

6. **Environmental Considerations**

- **Safety**: Handling silicon nitride requires safety measures due to its potential for dust formation, which can be harmful if inhaled.

- **Waste Management**: Proper disposal of machining waste is important to avoid environmental contamination.

Conclusion

Machining custom parts from silicon nitride requires expertise in both material science and machining technologies. It involves careful selection of tools, precise control over the machining process, and thorough quality assurance steps to produce parts that meet the stringent requirements of various applications.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords