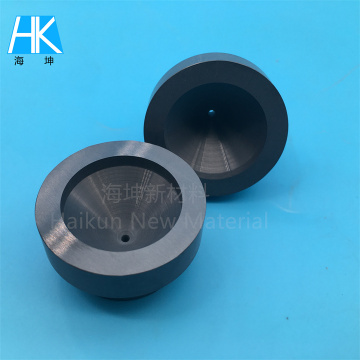

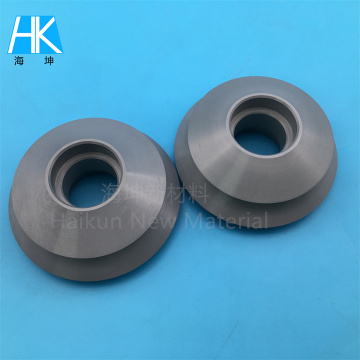

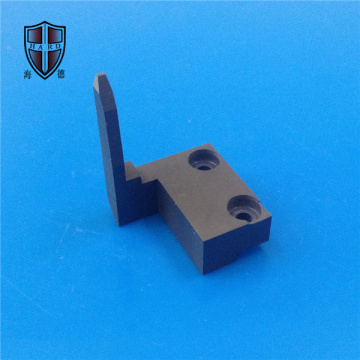

Silicon Nitride (Si3n4 ) Ceramic Thread Parts Fasteners

-

$1.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs |

| Supply Ability: | 1000000pcs |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,DDU,CFR,Express Delivery,CIF,CPT,DDP,EXW |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Dongguan |

Silicon Nitride (Si3n4 ) Ceramic Thread Parts Fasteners

Silicon nitride (Si3N4) is a ceramic material that offers a wide range of benefits, including high strength, excellent wear resistance, and good thermal stability. It's used in various industries due to its unique properties. One application where silicon nitride finds significant use is in the manufacturing of ceramic thread parts and fasteners.

Key Properties of Silicon Nitride:

1. **High Strength**: Silicon nitride is known for its high compressive strength, which makes it suitable for applications requiring high mechanical loads.

2. **Wear Resistance**: It has superior wear resistance compared to many other materials, making it ideal for components subjected to high friction or abrasive conditions.

3. **Low Coefficient of Thermal Expansion**: This property allows it to maintain dimensional stability under varying temperatures, reducing the risk of thermal stresses.

4. **Corrosion Resistance**: It is resistant to corrosion by many chemicals, enhancing its durability in harsh environments.

5. **Thermal Stability**: Silicon nitride can withstand high temperatures without significant degradation of its properties.

Applications in Ceramic Thread Parts and Fasteners:

- **High-Temperature Environments**: In industries like aerospace, where components must operate at high temperatures, silicon nitride fasteners and thread parts can provide reliable performance without degradation.

- **Automotive Industry**: In engines and transmissions, where lightweight yet strong components are crucial for efficiency, silicon nitride can offer improved performance and durability.

- **Power Generation**: Components in turbines and heat exchangers benefit from the high-temperature stability and wear resistance of silicon nitride.

- **Medical Devices**: In orthopedic implants, where biocompatibility and durability are paramount, silicon nitride can be used to create long-lasting and effective medical devices.

Manufacturing Process:

The production of silicon nitride parts often involves advanced techniques such as powder metallurgy, chemical vapor deposition (CVD), or hot isostatic pressing (HIP). These methods allow for precise control over the material's composition and microstructure, leading to parts with tailored properties.

Advantages Over Traditional Materials:

Compared to metals and traditional ceramics, silicon nitride offers several advantages:

- **Increased Durability**: Due to its superior mechanical properties, silicon nitride parts can last longer and require less maintenance.

- **Reduced Weight**: Its high strength-to-weight ratio makes it an attractive option for weight-sensitive applications.

- **Enhanced Performance**: In applications where high temperature, wear, or chemical resistance is critical, silicon nitride can outperform conventional materials.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords