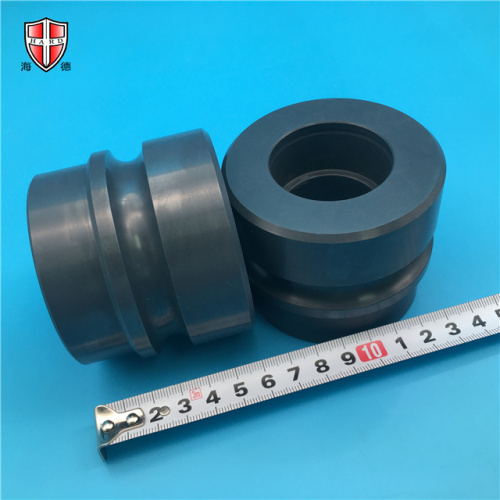

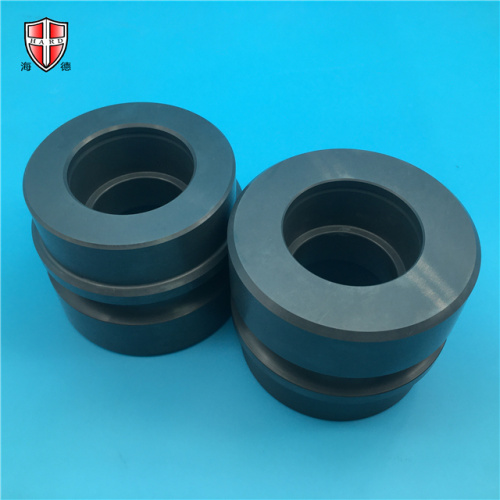

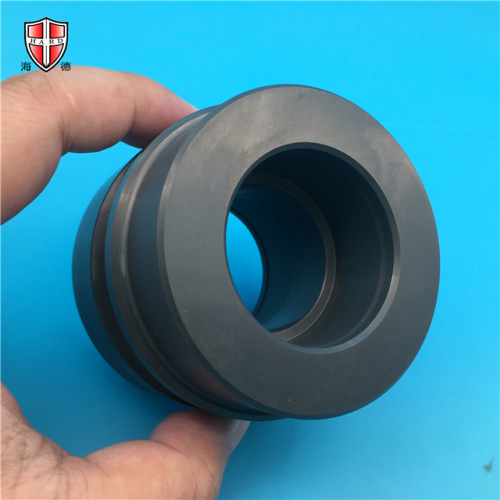

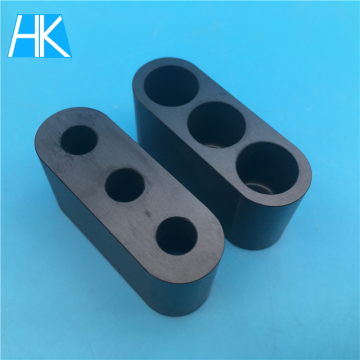

R groove Silicon Nitride Bearing Sleeve Bush Roller

-

$0.5010-99 Piece/Pieces

-

$0.30100-999 Piece/Pieces

-

$0.201000-9999 Piece/Pieces

-

$0.10≥10000 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1,000,000 pcs/Month |

|---|---|

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

R groove Silicon Nitride Bearing Sleeve Bush Roller

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramics:

Silicon nitride LED curing and post-curing refers to the curing of encapsulated epoxy resin. The general epoxy resin curing condition is 135°C for 1 hour. Molded packaging is generally done at 150°C for 4 minutes. Post-curing is to allow the epoxy resin to completely cure while thermally aging the LED. Post-curing is very important to improve the bond strength of epoxy resin to the bracket (PCB). Trust our silicon nitride ceramics and silicon nitride ceramic parts to provide reliable, efficient solutions for your LED production needs. Typical conditions are 120°C, 4 hours.

Since LEDs are connected together (not individually) when produced, Lamp packaged LEDs use ribs to cut off the ribs of the LED bracket. SMD-LED is on the PCB board and requires a dicing machine to complete the separation work. Test the photoelectric parameters of LEDs, check the overall dimensions, and sort LED products according to customer requirements. With the tremendous advancement of LED technology in the 1990s, not only did the luminous efficiency exceed that of incandescent lamps, and the light intensity reached the level of candlepower, but the colors also covered the entire visible spectrum from red to blue. This technological revolution from the indicator light level to beyond the general light source level has given rise to a variety of new applications, such as automobile signals, traffic lights, large outdoor full-color displays, special lighting sources, etc.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature resistance (1200°), good thermal diffusivity, good thermal shock resistance (avoiding sudden temperature changes), good insulation, and low density. The overall performance is the best among most structural ceramics.

Data Sheet↓

Color: black grayDensity: >3.2g/cm3

Hardness: HRA90

Vickers hardness (Hv50): >1550 HV0.5

Elastic modulus: 290Gpa

Bending strength: >600Mpa

Compressive strength: 2500Mpa

Elastic modulus (25°C): 65Gpa

Fracture toughness: >6.0 Mpam1/2

Maximum operating temperature: 1200°C

Thermal conductivity: 15-20 W(mK)

Thermal expansion coefficient: >3.1 10-6/°C

Thermal shock resistance: 500 △T°C

Specific heat capacity: 700 KJ/kg.K

Dielectric strength: 1 KV/mm

Dielectric constant: er

Volume resistivity (20℃): 1.0*10(12)Ω.cm

Application industries:

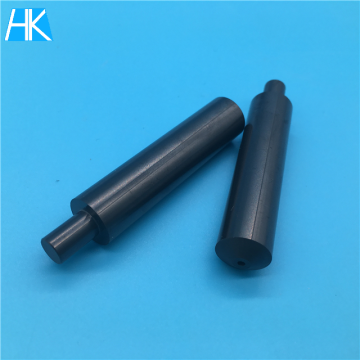

Machinery, electronics, semiconductor, chemical industry, petroleum, smelting.

Specific application:

Welding shafts, electronic substrates, plungers, nozzles, sliding guides, diesel engine parts, metal forming, shaft wheels, etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords