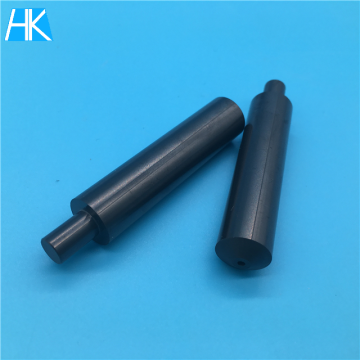

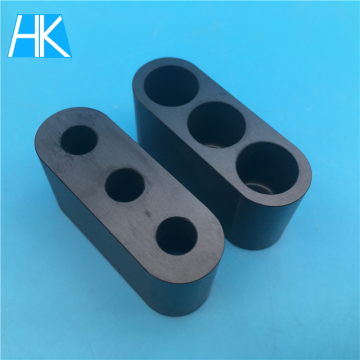

silicon nitride ceramic industrial threaded bolt screw

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

silicon nitride ceramic industrial threaded bolt screw

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

With the increase of nickel content in magnetic card austenitic stainless steel, silicon nitride ceramics reduces the critical carbon content for intergranular corrosion, that is, the intergranular corrosion sensitivity of steel increases. As for the resistance to pitting and crevice corrosion of austenitic stainless steel Performance, the role of nickel is not significant. In addition, nickel also improves the high temperature oxidation resistance of austenitic stainless steel. This is mainly due to the improvement of the composition of the chromium oxide film, the structure and performance of the nickel, and the higher the nickel content, the more harmful it is. This is mainly due to the low melting point nickel sulfide at the grain boundary in the steel. Generally speaking, simple silicon nitride (and chromium manganese nitrogen) austenitic stainless steel is only used for media that require rust resistance and oxidation resistance (such as nitric acid) Under the conditions of use, molybdenum, as an important alloying element in austenitic stainless steel, is added to steel to further expand its use range. The role of molybdenum is mainly to improve steel in reducing media. Both molybdenum and chromium are elements that form and stabilize ferrite and expand the ferrite phase region. The ability of molybdenum to form ferrite is equivalent to that of chromium. Molybdenum also promotes the precipitation of intermetallic phases in austenitic stainless steels, such as σ phase, κ phase, and Laves equivalent, which will adversely affect the corrosion resistance and mechanical properties of the steel, especially resulting in a decrease in plasticity and toughness. In order to maintain a single austenitic structure in austenitic stainless steel, as the content of molybdenum in the steel increases, the content of austenite-forming elements (silicon nitride, nitrogen, manganese, etc.) should also be increased accordingly to maintain the ferrite in the steel. Body and austenite form the balance between the elements.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, ceramic plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords