custom made silicon nitride nitride silikoni qeramike parts

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

custom made silicon nitride nitride silikoni qeramike parts

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

Slide box: It is the control box for the feed movement of the lathe. It is equipped with a mechanism that converts the rotary motion of the light rod and the lead screw into the linear motion of the tool post. The longitudinal and transverse feed motion of the tool post is realized through the light bar transmission. And rapid movement, the tool holder is driven by the lead screw to make a longitudinal linear movement, so as to turn the thread. Tool holder: There are two layers of skateboards (medium and small skateboards), bed saddle and tool holder body. Used to install the turning tool and drive the turning tool to move longitudinally, laterally or diagonally. Tailstock: Installed on the bed rail, and move longitudinally along this rail to adjust its working position. The tailstock is mainly used to install the rear center to support longer workpieces. Drills and reamers can also be installed for hole processing. Bed: It is a large basic part of a lathe with a high precision guide (mountain guide and flat guide). It is used to support and connect the various parts of the lathe, and ensure that each part has an accurate relative position when working. Cooling device: The cooling device mainly uses a cooling water pump to pressurize the cutting fluid in the water tank and spray it to the cutting area to reduce the cutting temperature, wash away the chips, and lubricate the processed surface to improve the tool life and the surface processing quality of the workpiece.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

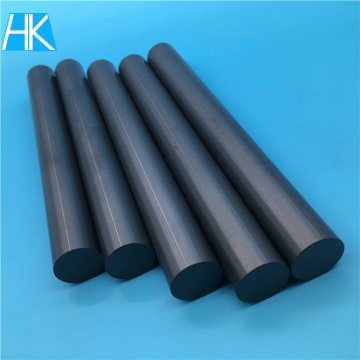

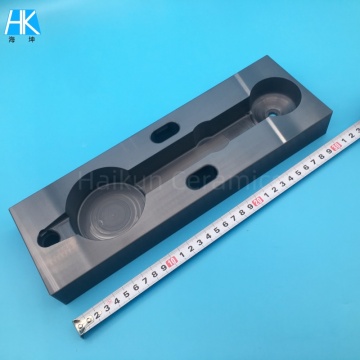

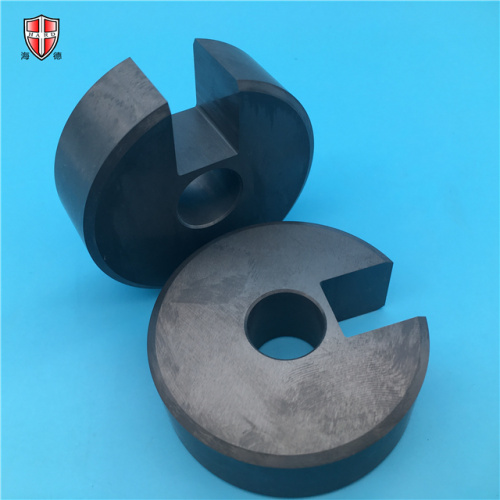

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords