OEM insulating electronic Si3N4 ceramic disc disk plate

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

OEM insulating electronic Si3N4 ceramic disc disk plate

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

General CNC machining usually refers to computer digital control precision machining, CNC machining lathe, CNC machining milling machine, CNC machining boring and milling machine, etc. CNC, also known as computer gongs, CNCCH or CNC machine tools, is actually a name in Hong Kong. Later, Alumina Ceramic Chuck Trough Groove High Strength Shape it was introduced into the Pearl River Delta of the mainland. It was actually CNC milling machines. In Guangzhou, Jiangsu, Zhejiang and Shanghai, people called "CNC machining centers". This is a new type of processing technology, the main work is to compile processing programs, that is, to convert the original manual work to computer programming. Of course, you need to have experience in manual processing. The feed processing route of the CNC lathe refers to the path that the Alumina Ceramic Chuck Trough Groove High Strength Shape turning tool moves from the tool setting point (or the fixed origin of the machine tool) until it returns to the point and ends the processing program, including the path of cutting processing and non-cutting such as cutting in and out of the tool Empty travel path. The feed route of finishing is basically carried out along the part contour sequence. Therefore, the focus of determining the feed route is to determine the feed route of rough machining and idle stroke. CNC machining has the following Alumina Ceramic Chuck Trough Groove High Strength Shape advantages: a large reduction in the number of tooling, processing complex shape parts without complicated tooling. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for new product development and modification. The processing quality is stable, the processing accuracy is high, and the repeat accuracy is high, which is suitable for the processing requirements of aircraft. In the case of multi-variety and small batch production, the production efficiency is higher, which can reduce the time of production preparation, machine tool adjustment and process inspection, and the cutting time is reduced due to the use of the best cutting amount. It can process complex profiles that are difficult to process by conventional methods, and even process some unobservable processing parts. The disadvantage of CNC machining is that the cost of machine tools is expensive and requires a high level of maintenance personnel.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

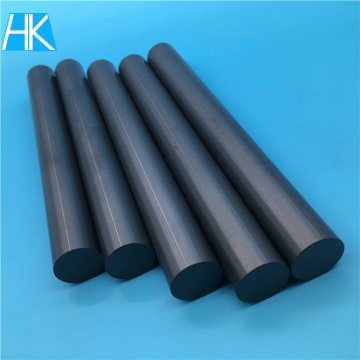

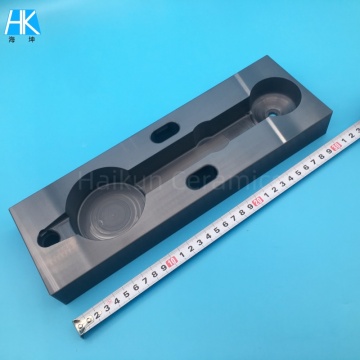

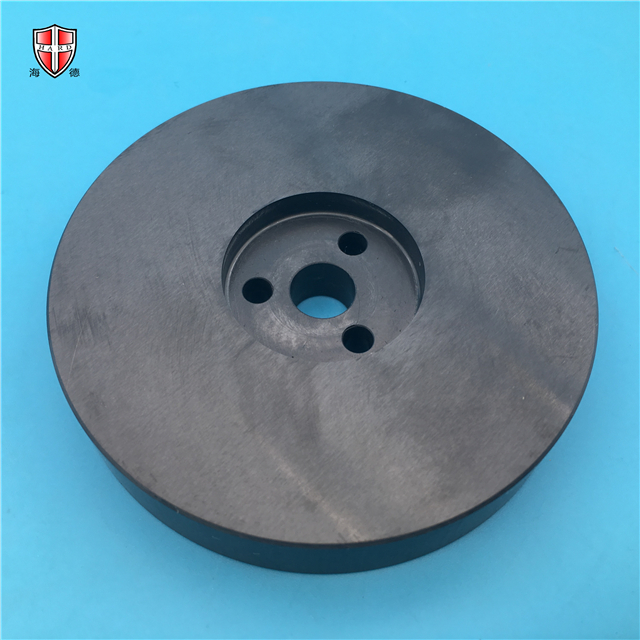

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords