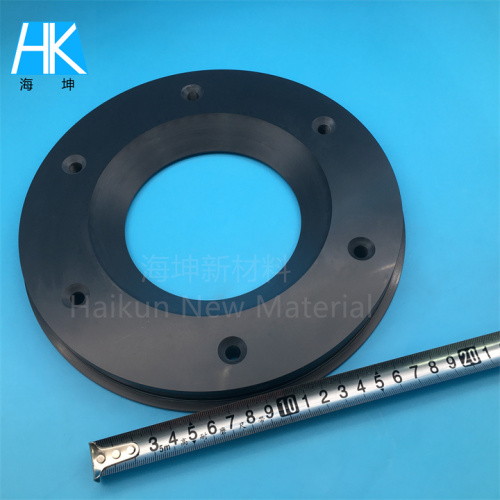

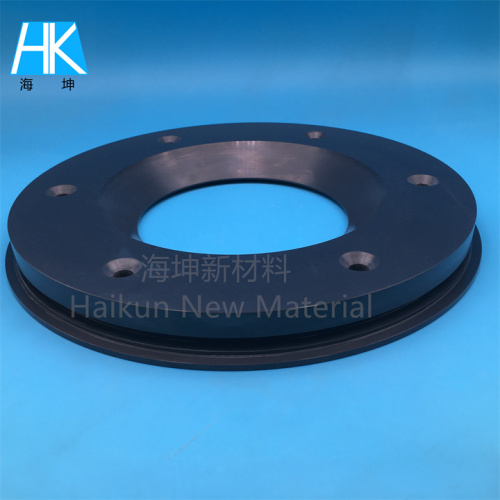

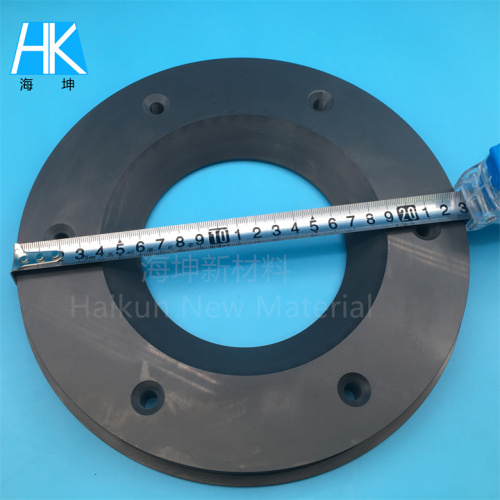

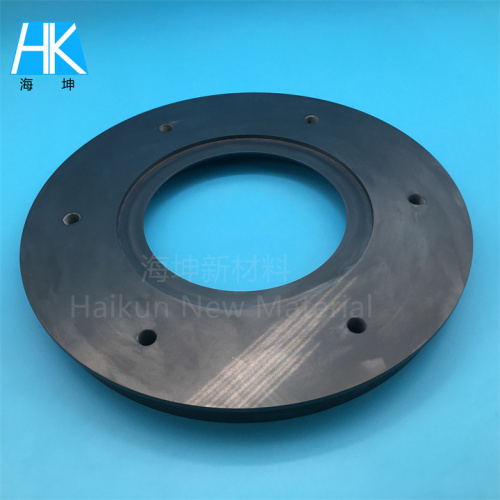

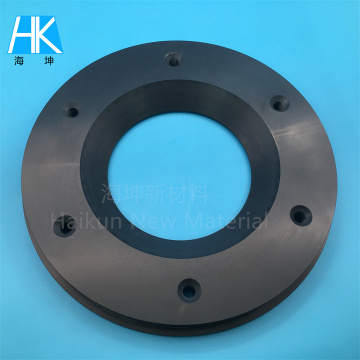

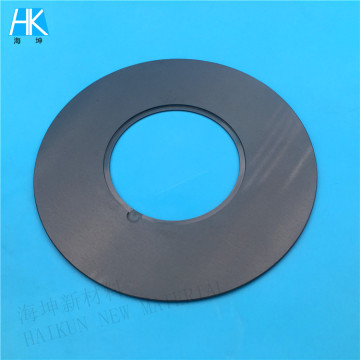

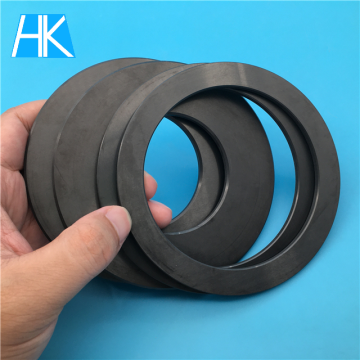

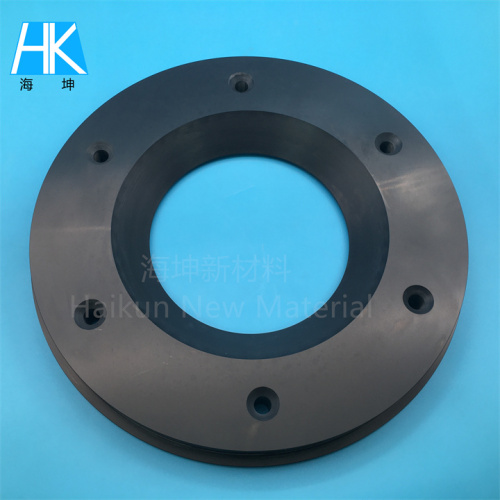

Insulation Finest GPSN Silicon Nitride Ceramic Spacer Ring

-

$2.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,DDU,CFR,Express Delivery,CIF,EXW,CPT,DDP |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Dongguan |

Silicon Nitride Ceramic Rings are components made from silicon nitride (Si₃N₄), a high-performance technical ceramic known for its exceptional mechanical and thermal properties. Here are some key points about silicon nitride ceramic rings:

1. **Silicon Nitride Ceramic Properties**:

- **High Strength**: Silicon nitride is exceptionally strong, especially at high temperatures.

- **High Hardness**: It has excellent wear resistance.

- **Low Thermal Expansion**: This property makes it resistant to thermal shock.

- **Chemical Stability**: It is highly resistant to corrosion and chemical attack.

- **Low Friction Coefficient**: It can be used in applications where low friction is required.

2. **Applications**:

- **Mechanical Seals**: Silicon nitride rings are often used as seal rings in mechanical seals due to their wear resistance and chemical stability.

- **Bearings**: They can be used in high-temperature or corrosive environments as bearing components.

- **Pumps and Valves**: Due to their strength and durability, they are suitable for use in harsh conditions within pumps and valves.

- **Electronics**: They can also be used in electronic packaging and other applications requiring high reliability and performance.

3. **Manufacturing Process**:

- Silicon nitride ceramic rings can be manufactured using various processes, including hot pressing, reaction bonding, and sintering with additives.

- The manufacturing process can influence the final properties of the ceramic, such as density, strength, and toughness.

4. **Design Considerations**:

- When designing with silicon nitride ceramic rings, factors like operating temperature, mechanical loads, and environmental conditions should be considered.

- Proper design ensures optimal performance and longevity of the component.

5. **Maintenance and Care**:

- While silicon nitride is durable, proper handling and maintenance are still important to ensure long-term performance.

- Avoiding sudden temperature changes and ensuring cleanliness can help maintain the integrity of the ceramic ring.

Dongguan Haikun New Material Co.,Ltd has been producing a wide range of precision machined industrial ceramic parts and providing ceramic technology solutions since 2007.

The main advanced ceramic materials include Zirconia, Alumina, Silicon Nitride, Macor glass, Silicon Carbide,Aluminum Nitride and Boron Nitride, etc.

Custom ceramic parts are widely used in machinery, semiconductor, aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum, etc.

If you have specific questions or need more detailed information about silicon nitride ceramic rings, feel free to ask us! What'sapp:+86-13823242056

Related Keywords