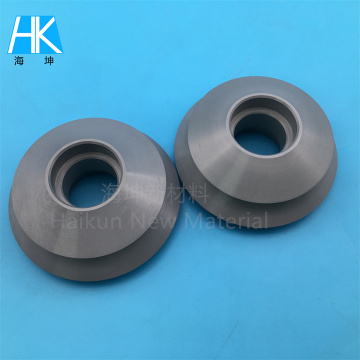

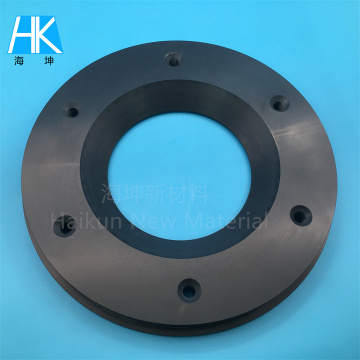

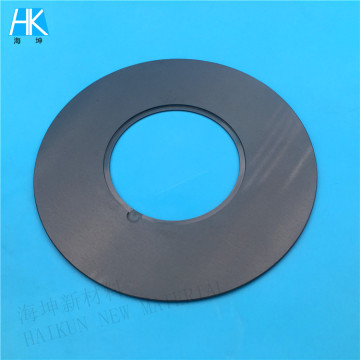

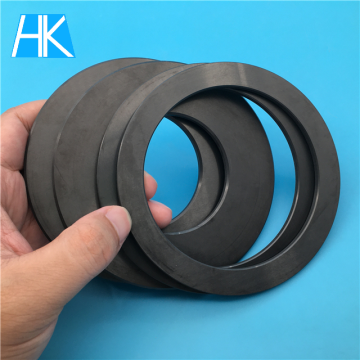

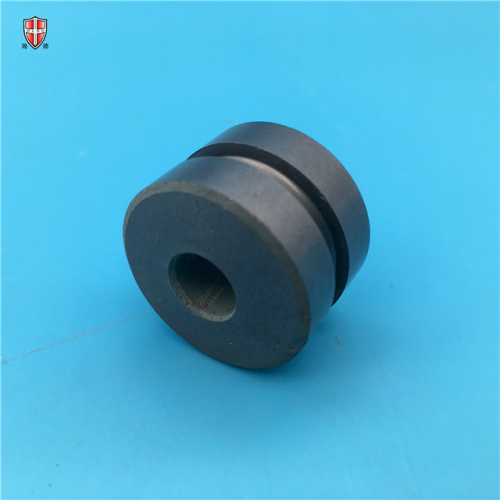

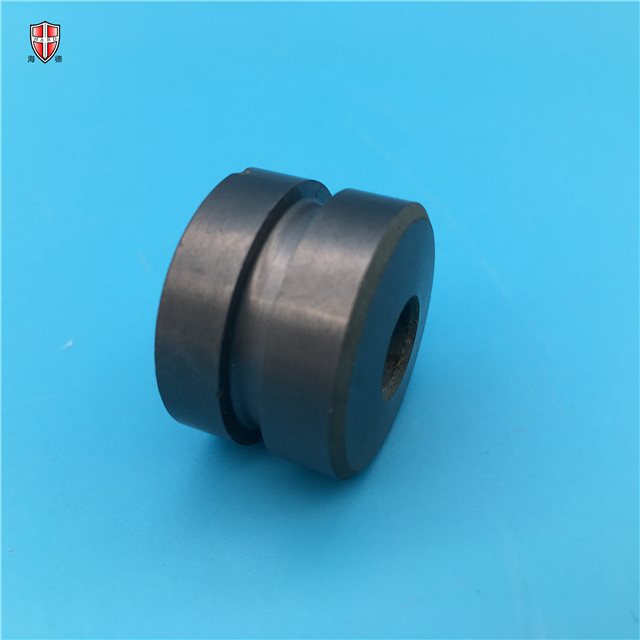

gas pressing sintering Si3N4 ceramic wheel roller

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

gas pressing sintering Si3N4 ceramic wheel roller

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

According to its etymology, it originally refers to the void, that is, the space with nothing. The vacuum in industry and vacuum science refers to when the pressure in Ceramic Substrate Hybrid Integrated Circuit Sheet the container is lower than the atmospheric pressure, the part below the atmospheric pressure is called vacuum, and the pressure in the container is called absolute pressure; another way of saying that is, where the pressure ratio is The space in a container with low atmospheric pressure is called a vacuum. Industrial vacuum has a difference in degree: when there is no pressure in the container, that is, when the absolute pressure is equal to zero, it is called complete vacuum; the rest are called incomplete vacuum. The vacuum in the physical theories before Dirac, such as special relativity, specifically refers to the state of space without any matter, corresponding to the complete vacuum in industry. According to the view of modern physical quantum field theory, Ceramic Substrate Hybrid Integrated Circuit Sheet vacuum is not empty, and it contains extremely rich physical content. The vacuum in theories such as special relativity is only an approximate situation when Planck's constant tends to zero. As far back as 1643, Italian physicist Torricelli discovered that there is atmosphere and atmospheric pressure in vacuum and natural space. When he filled a long glass tube with one end closed with mercury and stood it upside down in a mercury tank, he found that the mercury surface in the tube dropped until it was 76 cm away from the mercury surface outside the tube. Torizelli believes that the space on the mercury surface of the glass tube is a vacuum, and the 76 cm high mercury column is due to atmospheric pressure.

In 1650, Germany's Gaelick made piston vacuum pumps.

In 1654, he conducted the famous Ceramic Substrate Hybrid Integrated Circuit Sheet Magdeburg hemisphere test in Magdeburg: two copper hemispheres with a diameter of 14 inches (35.5 cm) combined together were evacuated with a vacuum pump, and then two groups of eight hemispheres were used. The horse pulled the copper ball in the opposite direction, but failed to separate the two hemispheres. This famous experiment once again proved that there is an atmosphere in space and that the atmosphere has a huge pressure. In order to commemorate Toritzelli's major scientific discoveries and contributions, the conventional vacuum pressure unit was named after him.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords