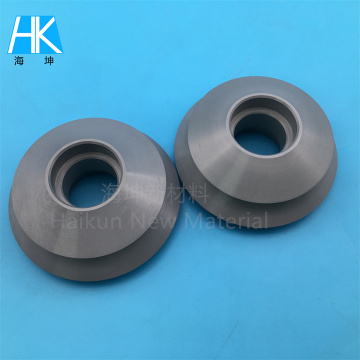

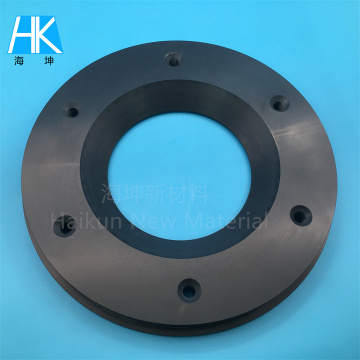

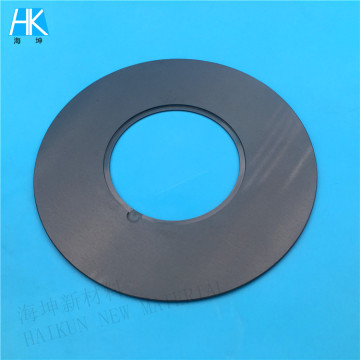

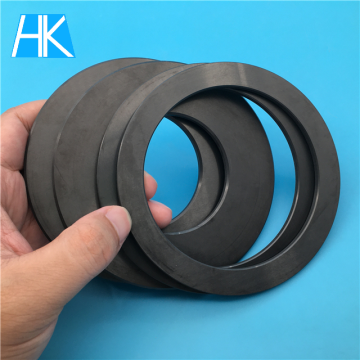

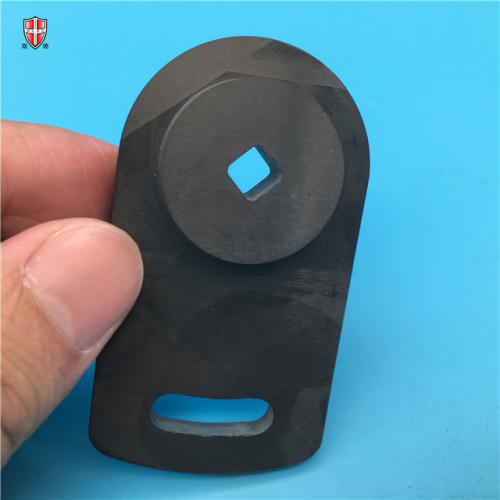

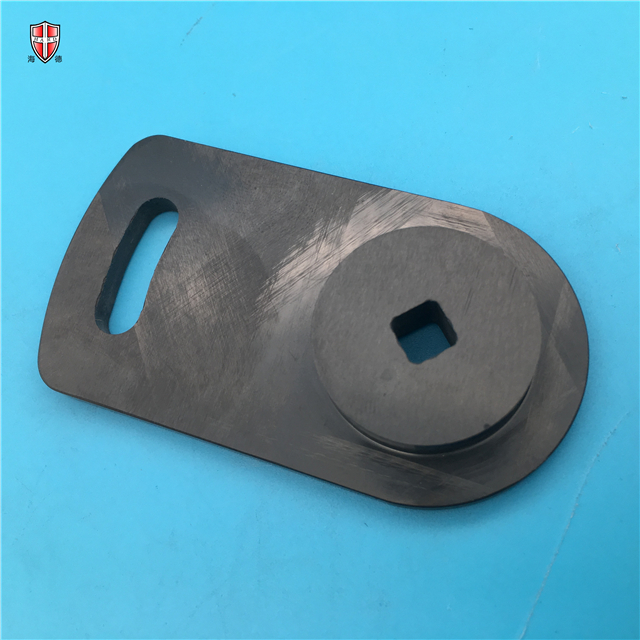

sintered silicon nitride ceramic machinery parts

-

$0.50≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

sintered silicon nitride ceramic machinery parts

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

Stamping is mainly classified by process, which can be divided into two categories: separation process and forming process. The separation process is also Laser Drilling Electronic Ceramic Substrate Strap Board called punching, and its purpose is to separate the stamping part from the sheet along a certain contour line while ensuring the quality requirements of the separated section. The purpose of the forming process Zirconia Ceramic Rings is to make the sheet metal Ceramic Disc plastically deform without breaking the billet to make a workpiece of the required shape and size. In actual production, multiple processes are often applied to one workpiece. Blanking, bending, shearing, stretching, bulging, spinning, and correction are the main stamping processes. (Blanking)

It is a basic stamping process that uses molds Laser Drilling Electronic Ceramic Substrate Strap Board to separate materials. It can be directly made into flat parts or prepare blanks for other stamping processes such as bending, drawing, and forming. It can also be cut and trimmed on the formed stamping parts. . Blanking is widely used in industries such as automobiles, household appliances, electronics, instrumentation, machinery, railways, communications, chemicals, light industry, textiles, and aerospace. The blanking process accounts for about 50% to 60% of the White Zirconia Ceramic entire stamping process. Bending: A plastic forming method of bending metal sheets, pipe fittings and profiles into a certain angle, curvature and shape. Bending is one of the main processes widely used in the production of stamping parts. The bending of metal materials is Laser Drilling Electronic Ceramic Substrate Strap Board essentially an elasto-plastic deformation process. After unloading, the workpiece will produce directional elastic recovery deformation, which is called springback. Springback affects the accuracy of the workpiece and is the key technology that must be considered in the bending process.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords