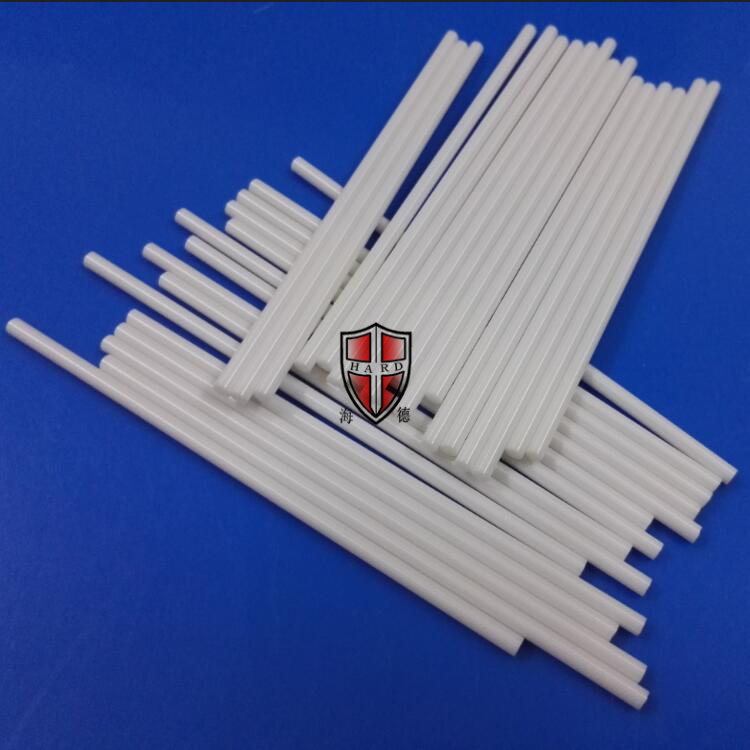

small zirconia ceramic welding pin spot welder needles

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

small zirconia ceramic welding pin spot welder needles

Reputation depends on quality, quality comes from Hard!

Zirconia Ceramic:

Ceramic knives are developed using high-precision ceramics, so they are called ceramic knives. The ceramic knife is known as the "noble knife". As a product of modern high-tech, it has the advantages unmatched by traditional metal cutters. It uses high-tech nano-zirconia as raw material, so the ceramic knife is also called "zirconium jewel", its elegance and luxury. It can be seen. 1. Mixing ingredients: ball milling → vibrating grinding → ball milling → adding glue → ball milling;Pressing the blank: The dry powder pressing process of the ceramic blade has high requirements on the powder morphology, the surface charge state of the powder and the granulation of the mixed powder, so the pressing process is difficult; Blank body discharging: The degumming process of the ceramic blade is similar to the production process of the cemented carbide tool;GPS + HIP processing: sintering process using atmosphere protection sintering (GPS) + hot isostatic pressing (HIP) processing technology; blade sharpening: the quality of the sharpening of the ceramic blade has a great impact on the performance of the tool; the installation handle: There are 3 large material handles, plastic handles (ABS), wooden handles, ceramic handles. The most widely used is the plastic handle, followed by the wooden handle. The wooden handle is best used in high-grade ceramic knives. The ceramic handle is easy to break.Test knives: For the ceramic blades produced in different batches and at different times, in addition to monitoring their performance indicators, test knives should be carried out before leaving the factory to verify the cutting performance of the blades. The test knives are generally completed on the machine tool of the factory; packaging inspection: inspection of damaged, defective products, defective products, qualified, packaging.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

Company Information:

Shenzhen Hard Precision Ceramic CO.,Ltd founded in 2007, located in Shenzhen of China. We are a company that integrates development, design, molding, sintering, production and sales of precision ceramic products. After 10 years of development, we have cooperated with more than 2000 customers and 60 universities; Our factory covers an area of 2000 square meters, 50 employees, and annual production value of nearly 20 million. We have a higher visibility and better reputation in the same industry.Our products include ceramic rods, tubes, plates, blocks and precision parts for industrial. We have all-line high precision equipments from ceramic forming, sintering to precision machining. Hope for a wide range of sincere cooperation with customers at home and abroad.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Show time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

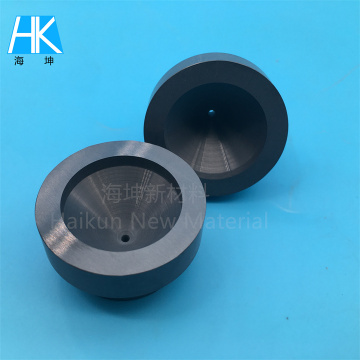

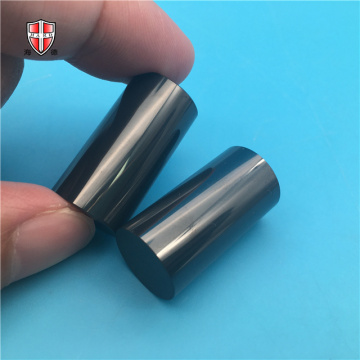

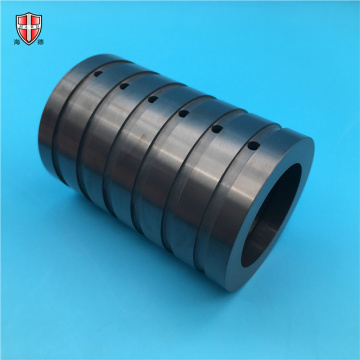

Products Show

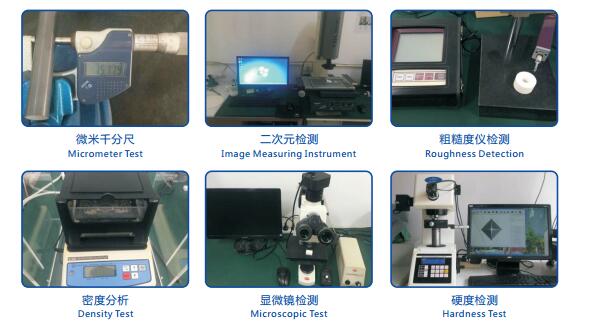

Factory Show

Our Team

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords