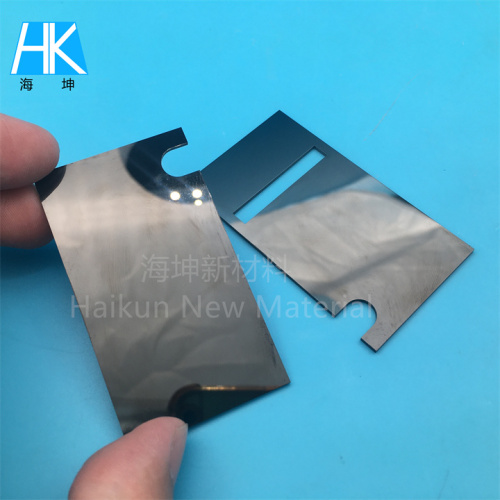

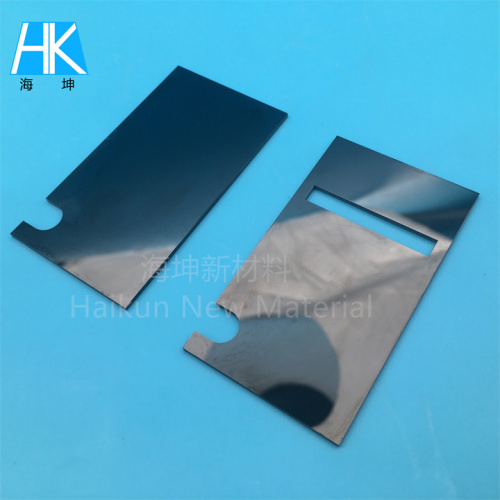

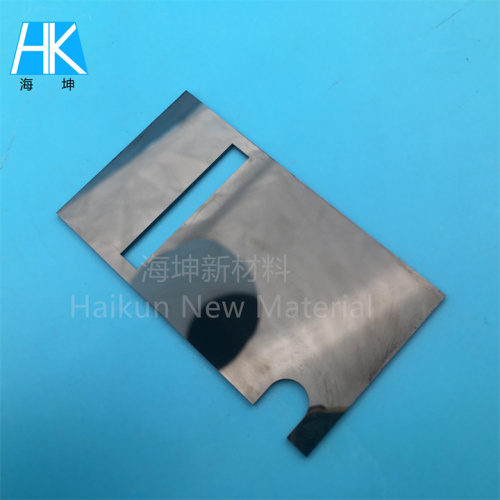

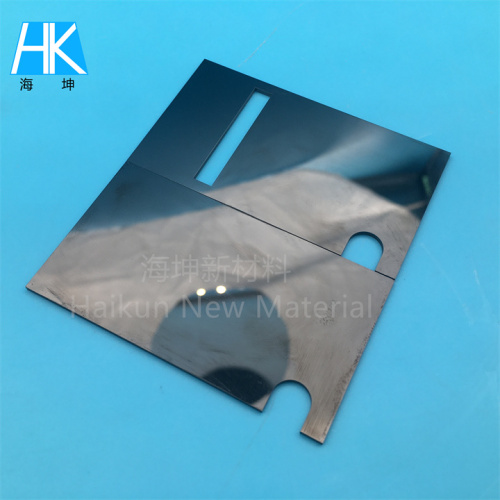

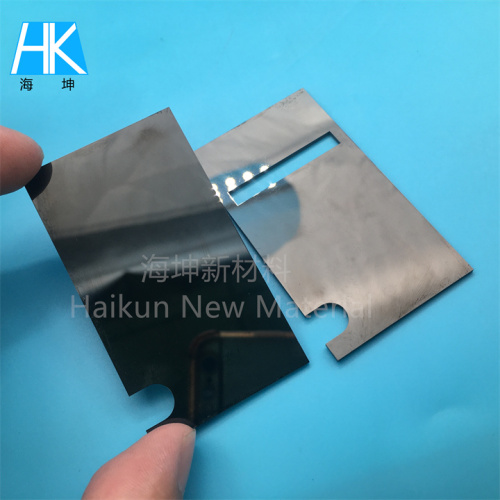

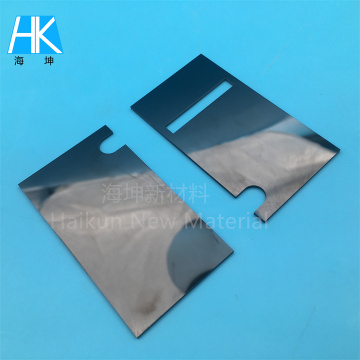

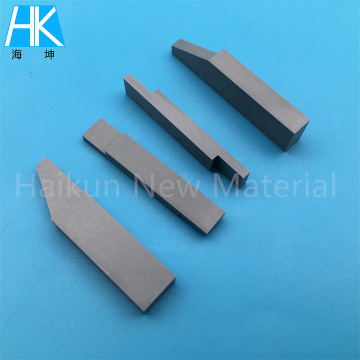

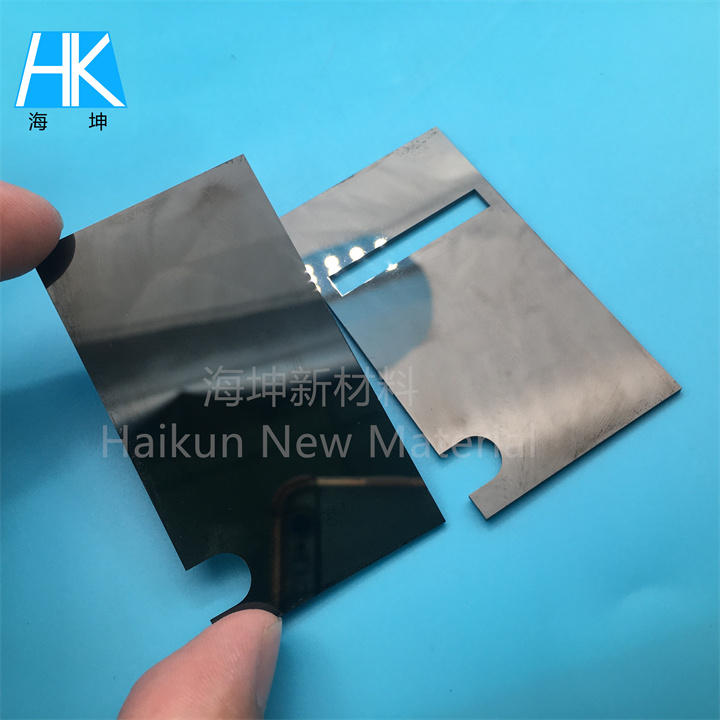

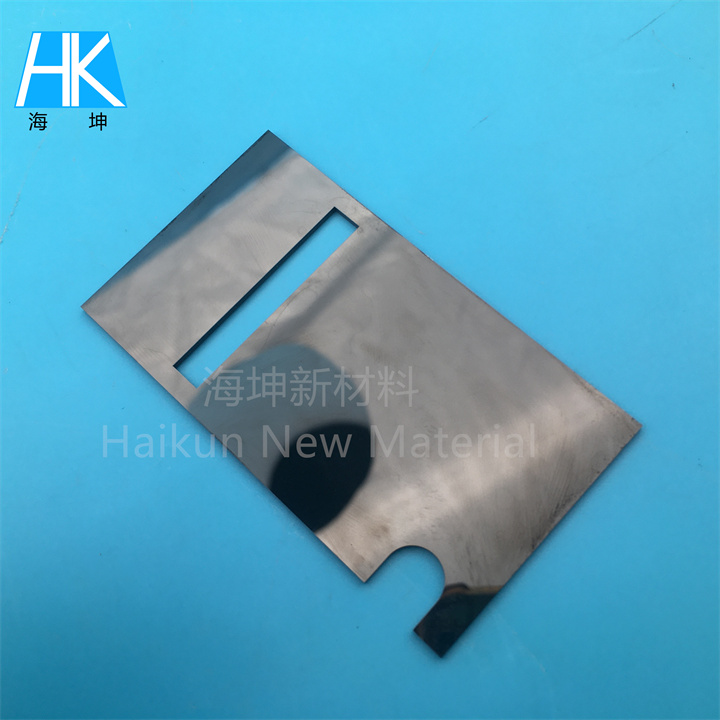

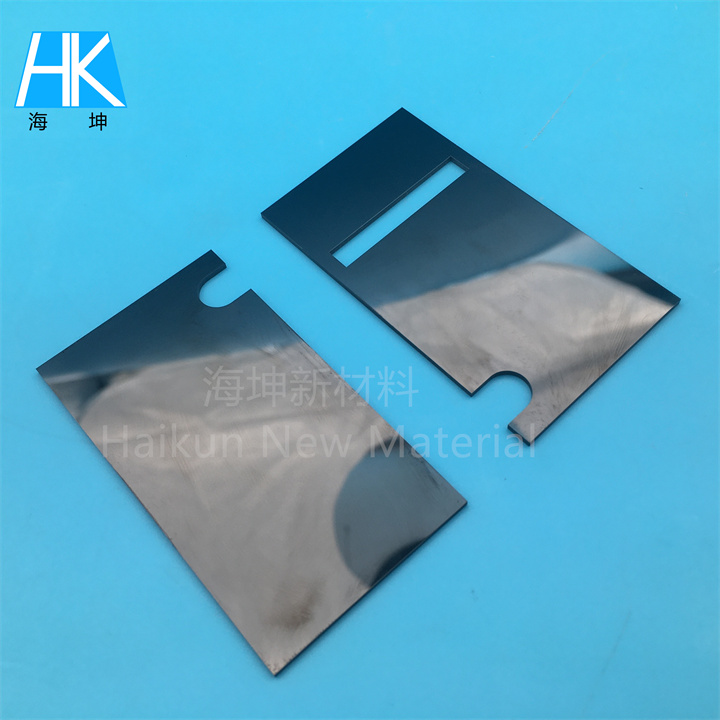

Precise Electronic Silicon Carbide SiC Ceramic Refractory Plate

-

$1.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal,Alipay |

| Incoterm: | FOB,DDU,Express Delivery,CFR,CIF,EXW,CPT,DDP |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Dongguan |

What's the Silicon Carbide SiC Ceramic material?

Silicon Carbide (SiC) ceramics are advanced ceramic materials with high hardness, high strength, high thermal conductivity and low coefficient of thermal expansion. It excels in high temperature, abrasive, and corrosive environments, and is therefore used in a wide variety of industrial applications including, but not limited to, mechanical seals, bearings, automotive components, semiconductor manufacturing equipment, and aerospace components.

For the application of SiC ceramic plates, the following aspects are considered:

1. Wear resistance: SiC ceramic plates have excellent wear resistance due to their extremely high hardness, and are suitable for environments that require long periods of resistance to wear.

2. High Temperature Resistance: SiC ceramic plates are able to maintain good mechanical properties at temperatures up to 1600°C, making them suitable for applications in high temperature environments.

3. Chemical Stability: SiC ceramic plates have good corrosion resistance to most acids and alkalis, suitable for use in corrosive environments.

4. Thermal conductivity: SiC ceramic plates have high thermal conductivity and can transfer heat efficiently, which makes it very useful in some applications that require good heat dissipation.

If a SiC Silicon Carbide ceramic plate needs to be customized, parameters such as size, shape, thickness, etc. are usually determined based on specific application scenarios, and surface treatments may be required to enhance specific properties or meet specific requirements. For example, they may be polished to improve surface finish or coated to further enhance properties such as wear and corrosion resistance.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords