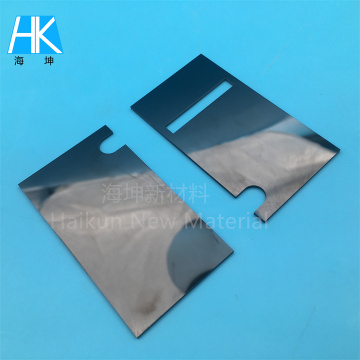

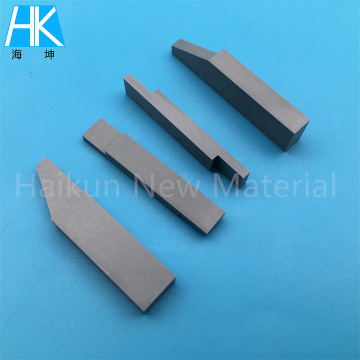

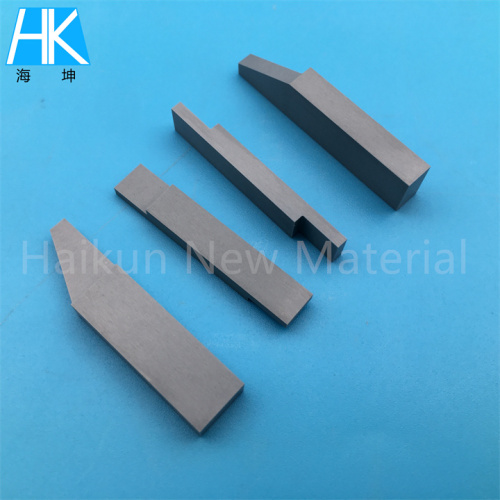

Superior SSIC Silicon Carbide Ceramic Cutting Tools

-

$3.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal,Alipay |

| Incoterm: | DDU,FOB,CFR,Express Delivery,CIF,EXW,CPT,DDP |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

Silicon Carbide (SiC/SiSiC/SSiC)

Silicon carbide behaves almost like a diamond. It is not only the lightest, but also the hardest ceramic material and has excellent thermal conductivity, low thermal expansion and is very resistant to acids and lyes. The variants SSiC (sintered silicon carbide) and SiSiC (silicon infiltrated silicon carbide) have established themselves. The latter is particularly suitable for the production of complex large-volume components.

With silicon carbide ceramics the material properties remain constant up to temperatures above 1,400°C. The high Young’s modulus > 400 GPa ensures excellent dimensional stability. These material properties make silicon carbide predestined for use as a construction material. Silicon carbide masters corrosion, abrasion and erosion as skillfully as it stands up to frictional wear. Components are used in chemical plants, mills, expanders and extruders or as nozzles, for example.

Silicon carbide ceramic cutting tools are a type of advanced cutting tool designed for precision machining applications. They offer several advantages over traditional metal-based cutting tools, including superior wear resistance, thermal conductivity, and chemical inertness.

Key Features of Silicon Carbide SiC Ceramic:

1. **Hardness**: Silicon carbide (SiC) is one of the hardest materials known, second only to diamond. This high hardness translates into excellent wear resistance, allowing these tools to maintain their sharpness longer than conventional tools.

2. **Thermal Conductivity**: SiC has excellent thermal conductivity, which helps dissipate heat generated during cutting operations more efficiently. This reduces the risk of thermal damage to both the tool and the workpiece.

3. **Chemical Inertness**: Silicon carbide is chemically inert, making it resistant to corrosion and degradation from various machining fluids and environmental conditions.

4. **Lightweight**: Compared to metallic cutting tools, silicon carbide ceramic tools are lighter, which can reduce operator fatigue and improve maneuverability.

5. **Precision Machining**: These tools are ideal for precision machining operations where tight tolerances and high surface finishes are required.

Silicon Carbide SiC Ceramic Applications:

- **Automotive Industry**: Used in the machining of aluminum alloys and other non-ferrous metals.

- **Aerospace Industry**: Ideal for machining composite materials and titanium alloys.

- **General Engineering**: Suitable for machining a wide range of materials including steel, cast iron, and non-metallic materials.

Maintenance and Handling:

Proper handling and maintenance are crucial for maximizing the performance and lifespan of silicon carbide ceramic cutting tools. It's important to avoid dropping them or subjecting them to excessive force, as this can cause cracking or chipping. Additionally, using appropriate coolants and lubricants can help extend tool life.

Overall, silicon carbide ceramic cutting tools are a valuable addition to any machine shop looking to achieve higher precision and efficiency in their machining processes.

Dongguan Haikun New Material Co.,ltd manufactures the kinds of technical ceramic blanks according to customer requirements and process them according to drawings.

Contact us to learn more about the possibilities of processing technical ceramcis Silicon Carbide Ceramic Cutting Tools Parts.

What'sapp: +86 13823242056

Related Keywords