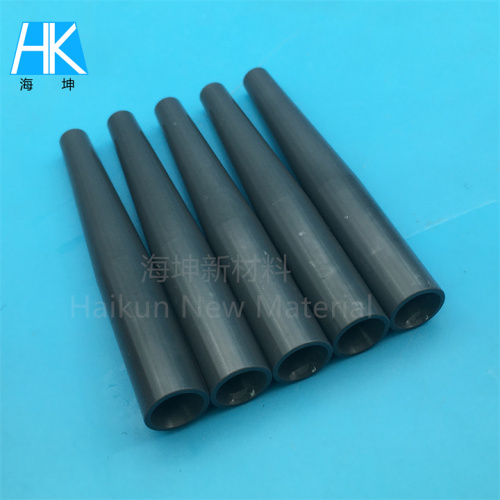

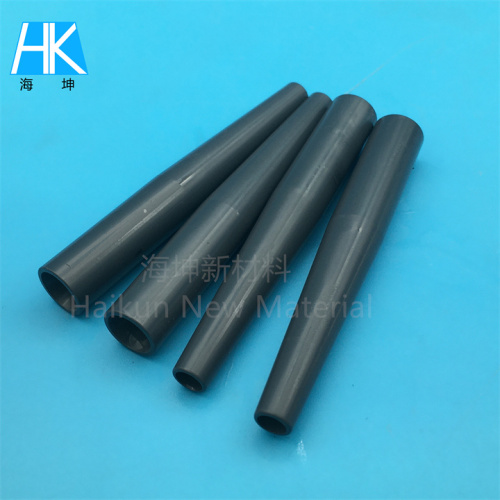

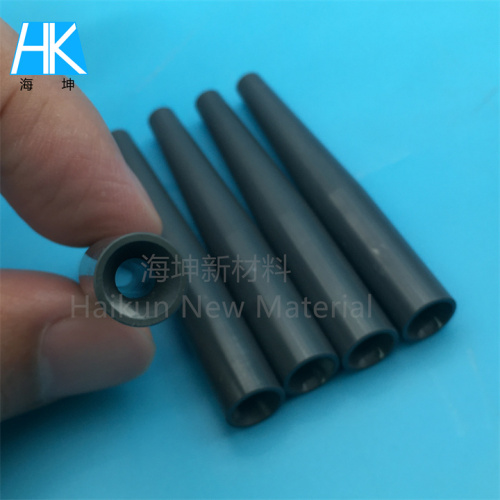

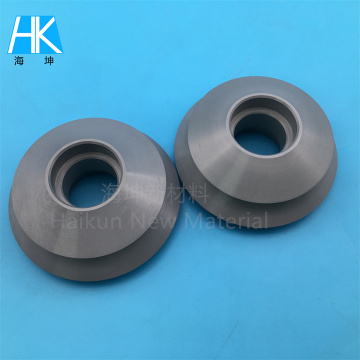

High Tolerance SSIC Silicon Carbide Tube Bushing

-

$3.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangdong, Dongguan

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal,Alipay |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,DDP,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangdong,Dongguan |

Product Description

Product Description

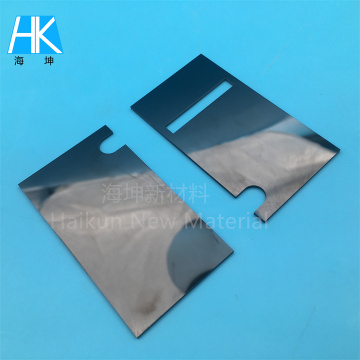

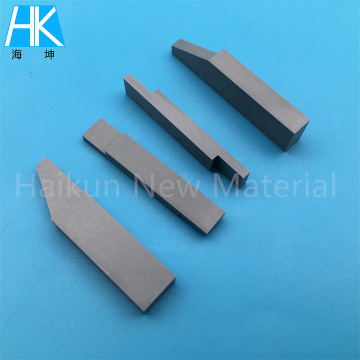

Silicon Carbide Ceramic Tube (SCCT) is a high performance ceramic material made of silicon carbide. This material is known for its excellent mechanical properties, high temperature stability, corrosion resistance and low coefficient of thermal expansion, making it very popular for a variety of industrial applications.

Silicon Carbide Ceramic Properties

1. **High Hardness and Strength**: Silicon Carbide Ceramics have high hardness and mechanical strength, which makes it capable of withstanding extreme working conditions.

2. **High Temperature Resistance**: This material can keep its physical and chemical properties stable at temperatures up to 1600°C.

3. **Corrosion resistance**: Silicon carbide ceramics show good resistance to most acids, alkalis and other chemicals.

4. **Low Coefficient of Thermal Expansion**: This means that the material dimensions change very little when the temperature changes, helping to minimize thermal stress and increase service life.

Application areas of Silicon Carbide

- **Semiconductor industry**: Used in the manufacture of packaging materials for semiconductor devices.

- **Heating elements**: Often used as heating elements in high-temperature furnaces due to their high-temperature resistance properties.

- **Chemical industry**: As reaction vessels or piping, especially in environments requiring resistance to strong corrosion.

- **Mechanical engineering**: Used in the manufacture of wear-resistant components such as bearings and seals.

- **Electronics industry**: for manufacturing high frequency circuit boards, heat sinks, etc.

Manufacturing process

Silicon carbide ceramic tubes are usually manufactured by powder metallurgy technology, which includes steps such as powder mixing, molding, and sintering. Silicon carbide powder is first mixed with appropriate additives, then molded into the desired shape by means of compression molding or injection molding, etc., and finally sintered at high temperatures to achieve the desired density and properties.

Caution

Despite the many advantages of silicon carbide ceramics, it is also important to note that they are brittle and prone to fracture during use. Therefore, special care needs to be taken to avoid mechanical shock and excessive stress concentrations during design and installation.

We hope this information will help you better understand silicon carbide ceramic tubes and their applications. If you have more specific questions or need further information, please feel free to let me know!

Dongguan Haikun New Material Co.,Ltd has been producing a wide range of precision machined industrial ceramic parts and providing ceramic technology solutions since 2007.

The main advanced ceramic materials include Zirconia, Alumina, Silicon Nitride, Macor glass, Silicon Carbide,Aluminum Nitride and Boron Nitride, etc.

Custom ceramic parts are widely used in machinery, semiconductor, aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum, etc

Welcome Contact with us: What'sapp:+86-13823242056

Related Keywords

Related Keywords

You May Also Like

You May Also Like