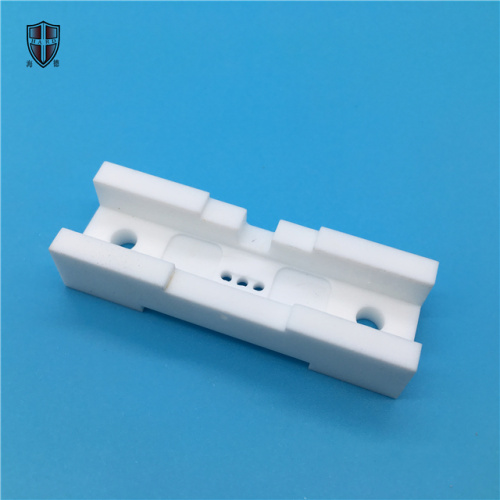

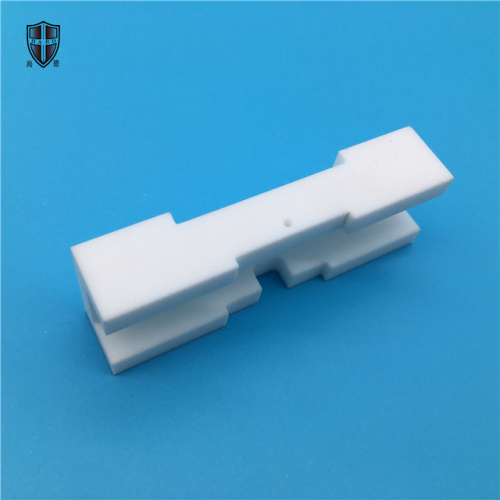

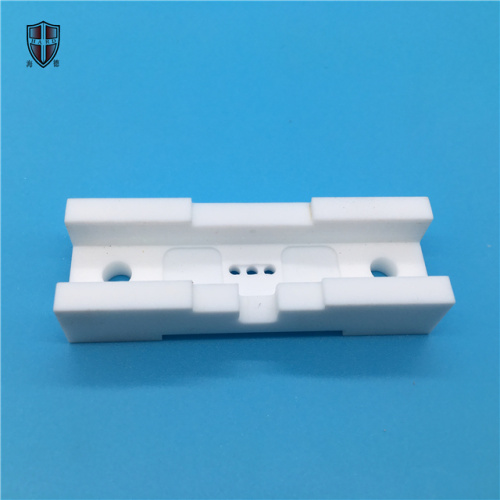

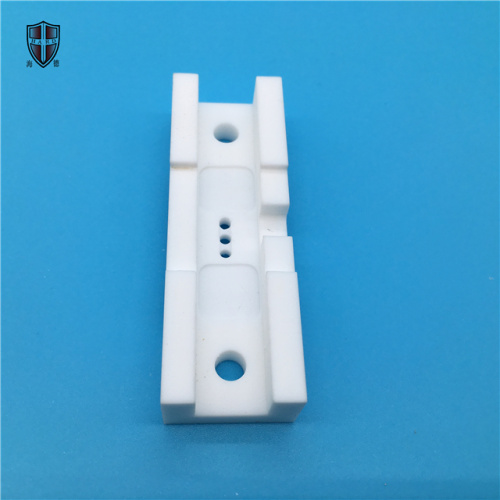

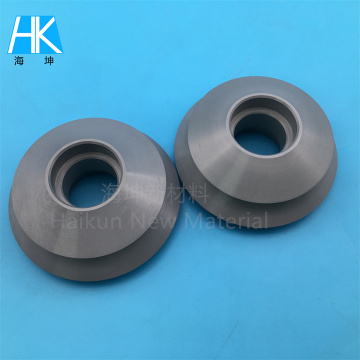

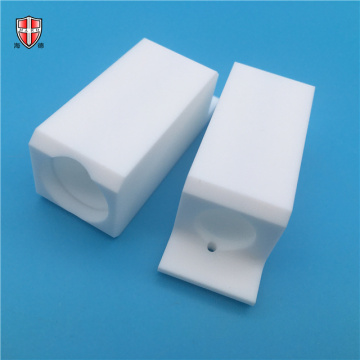

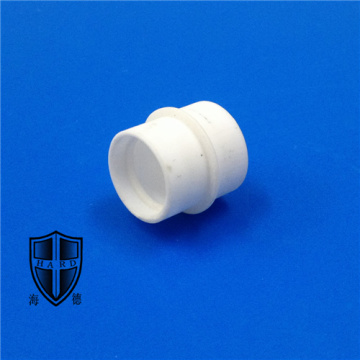

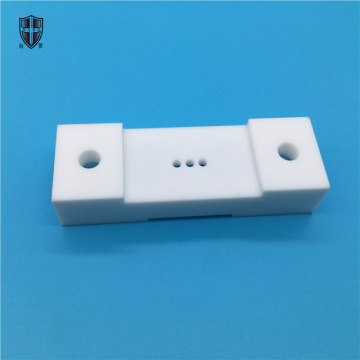

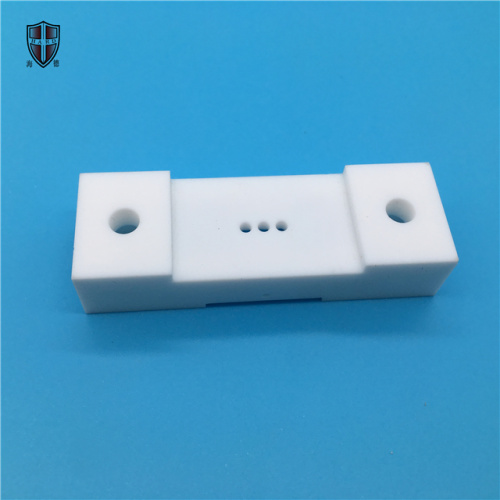

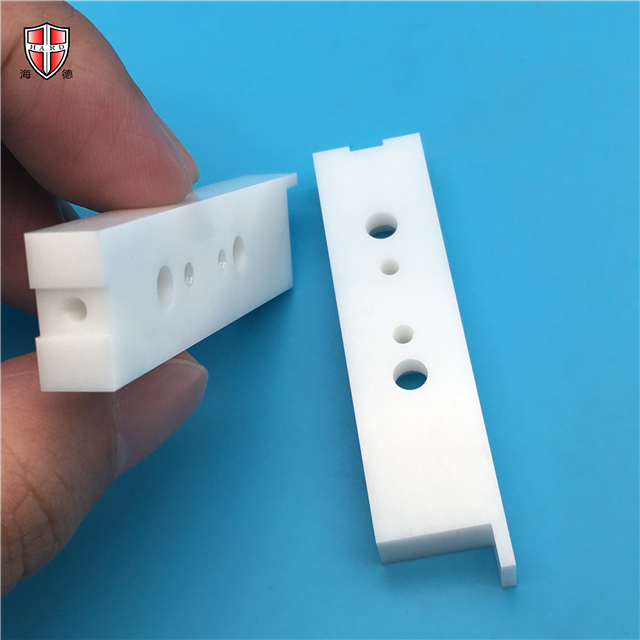

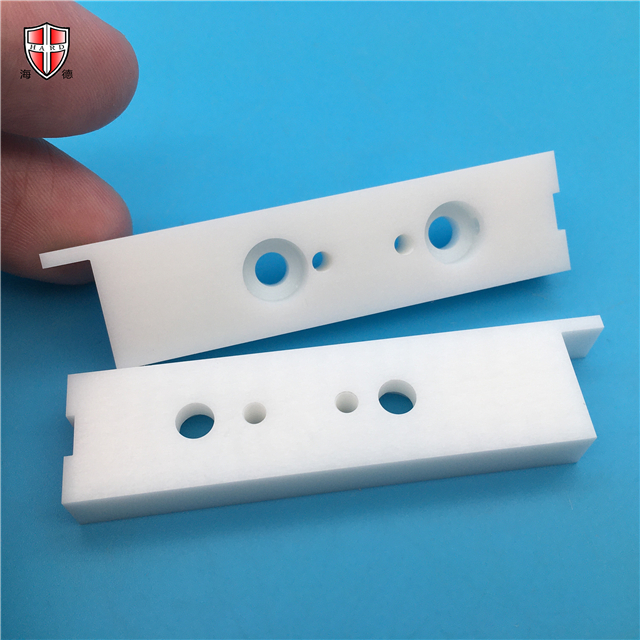

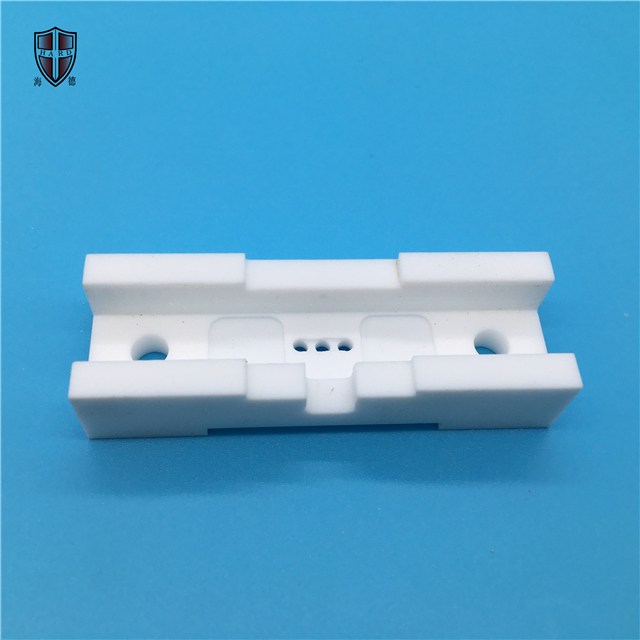

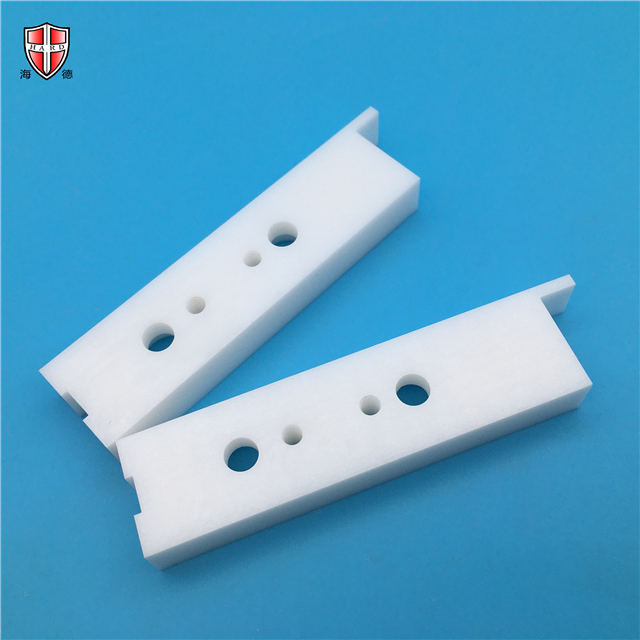

machinable engineering macor mica galss ceramic parts

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

Machinable engineering macor mica galss ceramic parts is a versatile and high-performance material. Constitutes the core element of Machinable Glass Ceramic Structure Parts in our precision engineering. This unique material combines superior properties, making it ideal for demanding applications in a wide range of industries. With its excellent electrical insulation properties, excellent mechanical strength and strong resistance to rapid thermal cycling, Macor ceramics show exceptional performance in situations where traditional materials are not suitable.

As an Industrial Ceramic material, Macor has the ability to shape complex shapes. We rely on the most advanced machining technology to produce Machinable Glass Ceramic Rod and tubular components according to your specific needs. Our team of experienced engineers are dedicated to providing products that are precisely tailored to your needs.

Machinable engineering macor mica galss ceramic parts is favored for its outstanding performance in many fields such as semiconductor manufacturing, aerospace, medical devices and more. It is able to withstand extreme conditions such as high temperature environments, corrosive media and violent thermal shocks, thus ensuring long-term stable performance and high reliability. Choosing Macor ceramics as a material for your project means you will be able to increase efficiency, reduce downtime, and optimize product quality, giving you an edge over the competition.

properties:

Good insulativity, high temperature(800°), good machinable property, can be made of rod and plate in short time.

Data Sheet↓

Density: 2.6g/cm3

Gas permeability: 0

Water Absorption: 0

Rockwell Hardness(45N): 40R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 108Mpa

Compressive Strength(20°C): 488Mpa

Modulus of Elasticity(25°C): 65Gpa

Thermal Conductivity(25°C):1.71W(m.K)

Thermal Expansion Coefficient: 7.2 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum Use Temperature: 800°C

Dielectric Strength: >30 KV/mm

Application industry:

Machinery, electronic, limitary, aerospace etc.

Specific application:

Machined equipment high temperature insulated parts, electronic equipment high temperature insulated parts.

Related Keywords