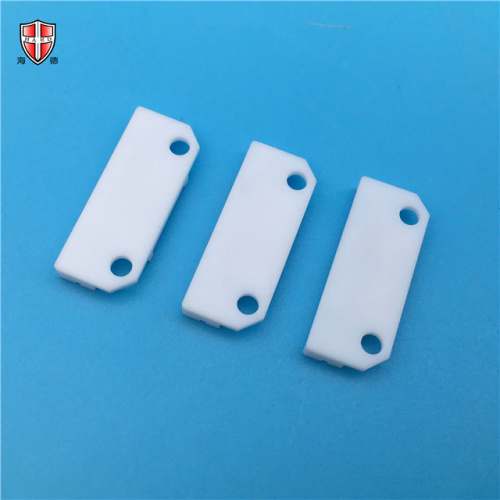

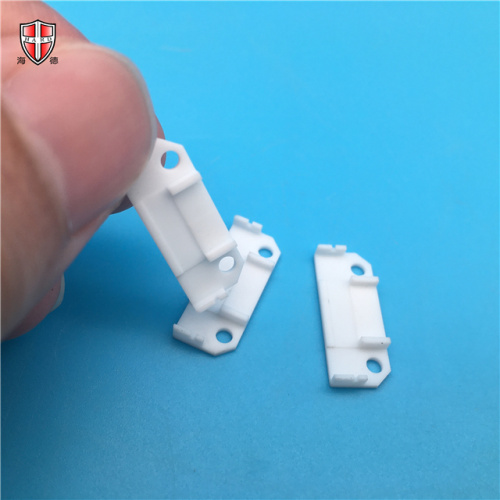

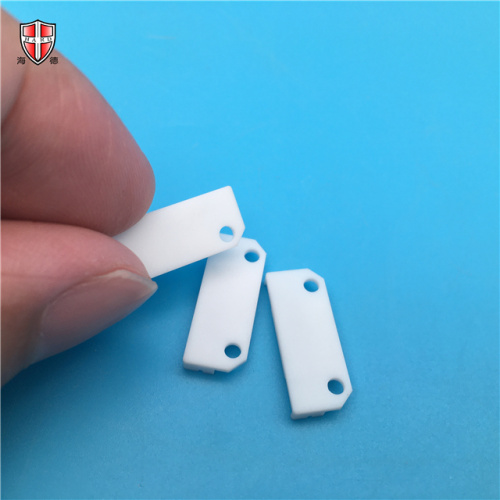

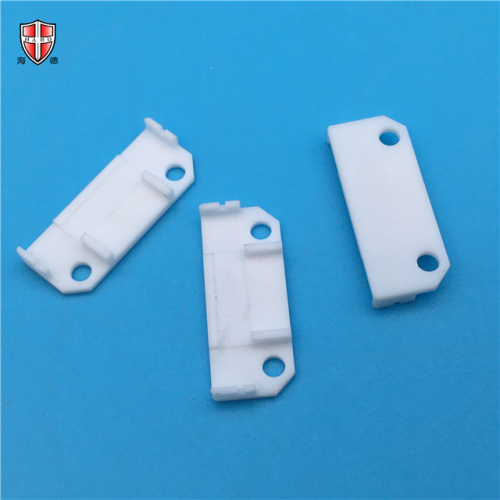

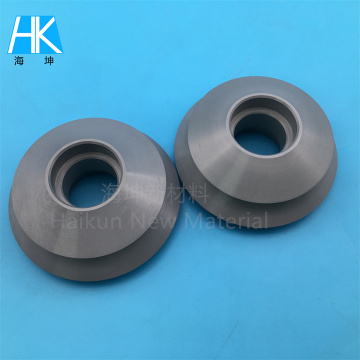

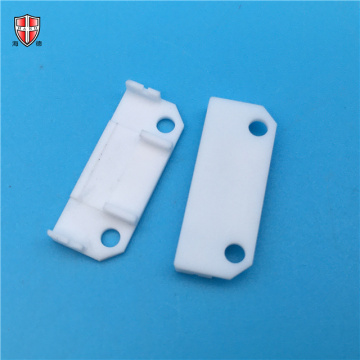

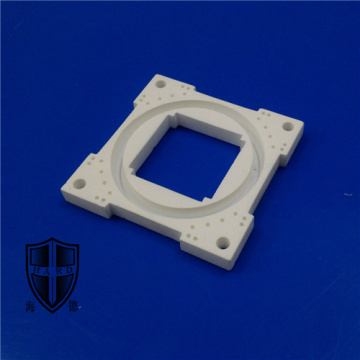

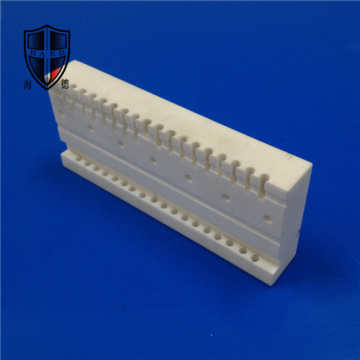

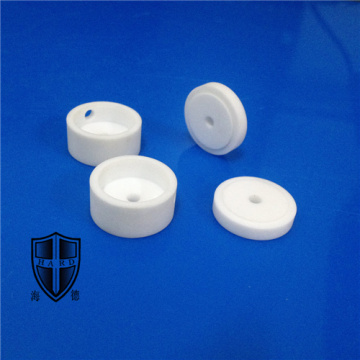

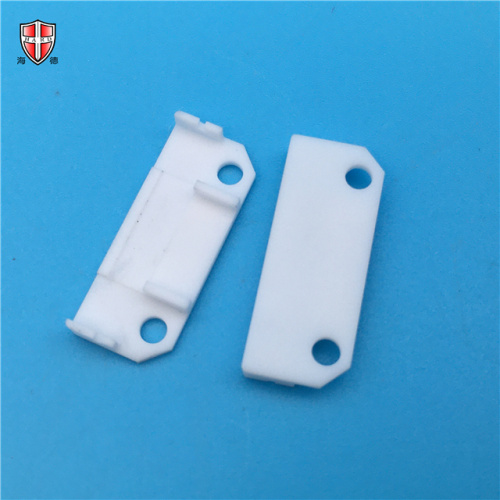

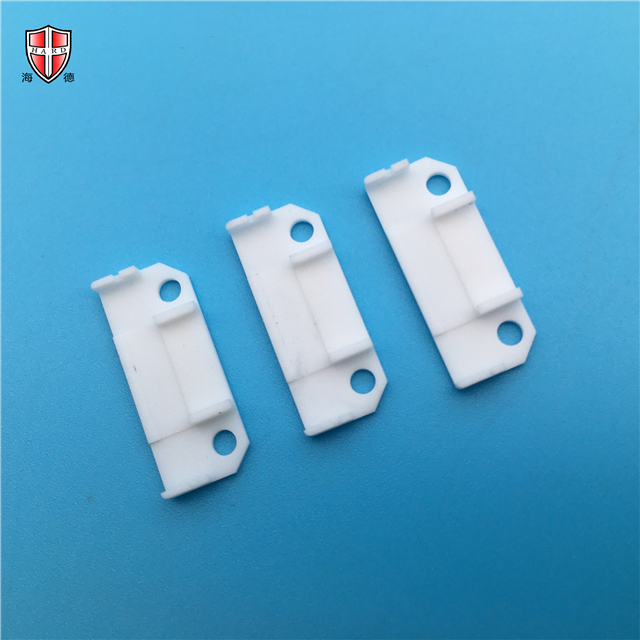

electronic macor mica ceramic machinery parts components

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

electronic macor mica ceramic machinery parts components

Reputation depends on quality, quality comes from Hard!

Macor Glass Machinable Glass Ceramic:

Thermosetting plastics refer to plastics that can be cured under heat or other conditions or have insoluble (melting) characteristics, such as phenolic plastics, epoxy plastics, etc. Thermosetting plastics are divided into formaldehyde cross-linked type and other cross-linked types. After thermal processing and molding, an infusible and insoluble cured product is formed, and the resin molecules are cross-linked into a network structure by a linear structure. Increased heat will decompose and destroy. Typical thermosetting plastics include phenolic, epoxy, amino, unsaturated polyester, furan, polysilicon ether and other materials, as well as newer polydipropylene phthalate plastics. They have the advantages of high heat resistance and resistance to deformation when heated. The disadvantage is that the mechanical strength is generally not high, but the mechanical strength can be improved by adding fillers to make laminates or molded materials. Thermosetting plastics made from phenolic resin as the main raw material, such as phenolic molded plastic (commonly known as Bakelite), are durable, dimensionally stable, and resistant to chemical substances other than strong alkalis. Various fillers and additives can be added according to different uses and requirements. For varieties that require high insulation performance, mica or glass fiber can be used as filler; for varieties that require heat resistance, asbestos or other heat-resistant fillers can be used; for varieties that require seismic resistance, various appropriate fibers or rubber can be used as fillers And some toughening agents to make high toughness materials. In addition, modified phenolic resins such as aniline, epoxy, polyvinyl chloride, polyamide, and polyvinyl acetal can also be used to meet the requirements of different applications. Phenolic resin can also be used to make phenolic laminates, which are characterized by high mechanical strength, good electrical properties, corrosion resistance, and easy processing. They are widely used in low-voltage electrical equipment.

properties:

Good insulativity, high temperature(800°), good machinable property, can be made of rod and plate in short time.

Data Sheet↓

Color: WhiteDensity: 2.6g/cm3

Gas permeability: 0

Water Absorption: 0

Rockwell Hardness(45N): 40R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 108Mpa

Compressive Strength(20°C): 488Mpa

Modulus of Elasticity(25°C): 65Gpa

Thermal Conductivity(25°C):1.71W(m.K)

Thermal Expansion Coefficient: 7.2 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum Use Temperature: 800°C

Dielectric Strength: >30 KV/mm

Volume Resistivity(20°C): >10(16)Ω.cm

Application industry:

Machinery, electronic, limitary, aerospace etc.

Specific application:

Machined equipment high temperature insulated parts, electronic equipment high temperature insulated parts.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords