Customized Macor Machinable Glass Ceramic Plate

-

$5.00≥1 Pound

- Min. Order:

- 1 Pound

- Min. Order:

- 1 Pound

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Dongguan, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,DDP,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Dongguan,Guangzhou |

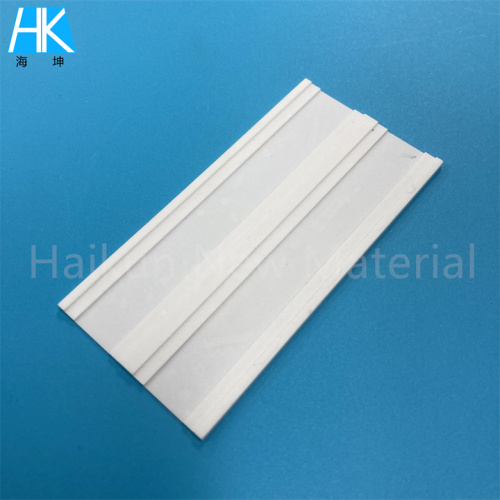

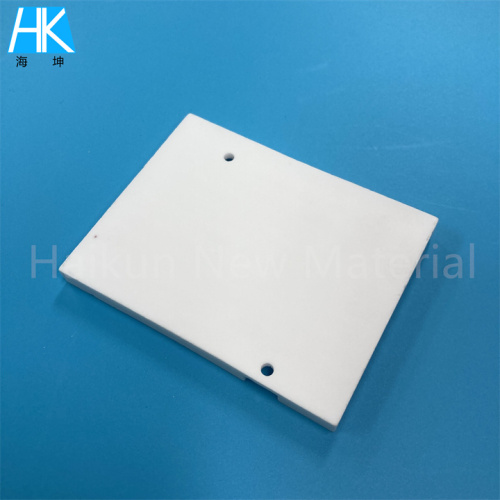

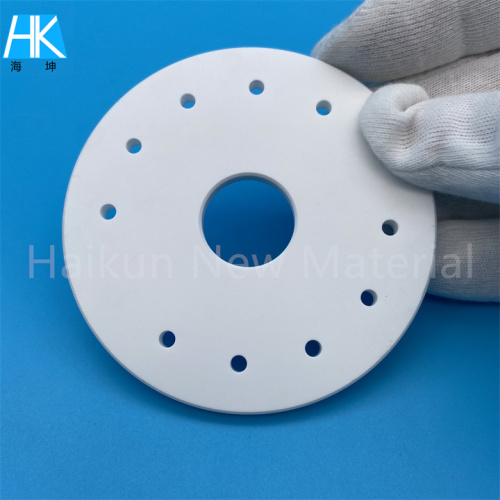

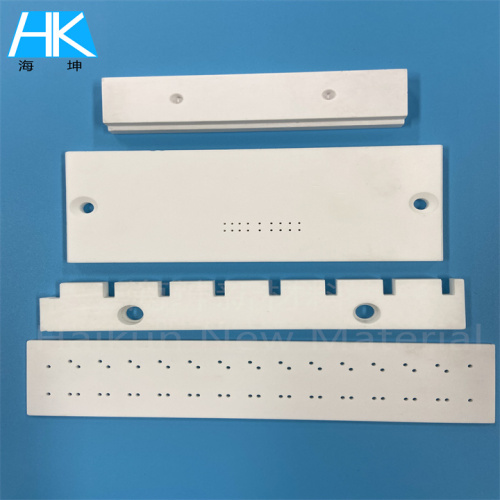

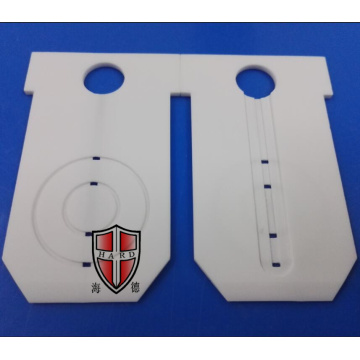

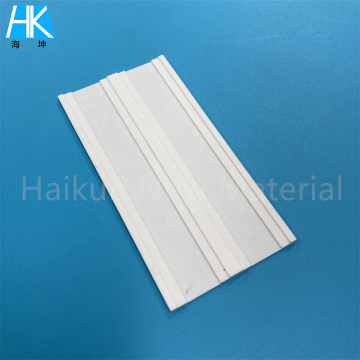

Customized Macor Machinable Glass Ceramic Plate

Machinable Macor Ceramic Parts' high-precision, high-performance applications due to its unique properties.The Macor Machinable Glass Ceramic Plate is an engineered product that combines the benefits of both ceramic and glass materials into one versatile composite.

Key Properties of Macor Machinable Glass Ceramic Plate:

1. **High Thermal Stability**: It can withstand temperatures ranging from -40°C to 650°C without significant changes in its mechanical properties. This makes it ideal for use in environments with extreme temperature fluctuations.

2. **Chemical Resistance**: Macor plates are highly resistant to corrosion from various chemicals, including acids, bases, and solvents, which makes them suitable for use in harsh chemical processing environments.

3. **Electrical Insulation**: Due to its non-conductive nature, Macor is often used in electrical components where insulation is required to prevent short circuits or leakage currents.

4. **Optical Transparency**: Depending on the composition, Macor can be made optically transparent, allowing it to be used in optical devices such as windows, mirrors, or lenses.

5. **Mechanical Strength**: Macor is known for its high strength and rigidity, making it capable of withstanding significant mechanical stresses without deformation or failure.

6. **Machinability**: One of the key advantages of Macor is its ease of machining using standard tools and techniques. This allows for the creation of complex shapes and intricate designs.

7. **Dimensional Stability**: Macor maintains consistent dimensions even under varying environmental conditions, ensuring precise fit and function in assemblies.

Applications of Macor Machinable Glass Ceramic Plate:

- **Precision Engineering**: Used in manufacturing precision parts for industries like aerospace, where high-temperature resistance and dimensional stability are crucial.

- **Optics**: Components for optical systems, such as mirrors, windows, and lenses in telescopes, microscopes, and laser systems.

- **Electronics**: In high-reliability electronic components where thermal stability and electrical insulation are necessary.

- **Medical Devices**: Due to its biocompatibility and resistance to chemicals, it's used in medical implants and surgical tools.

- **Research and Development**: In scientific research where materials need to withstand extreme conditions or have specific physical properties.

To utilize Macor Machinable Glass Ceramic Plate effectively, it's important to follow proper handling procedures and use the appropriate machining techniques to avoid cracking or chipping. Always consult the manufacturer's guidelines for best practices and specific application recommendations.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords