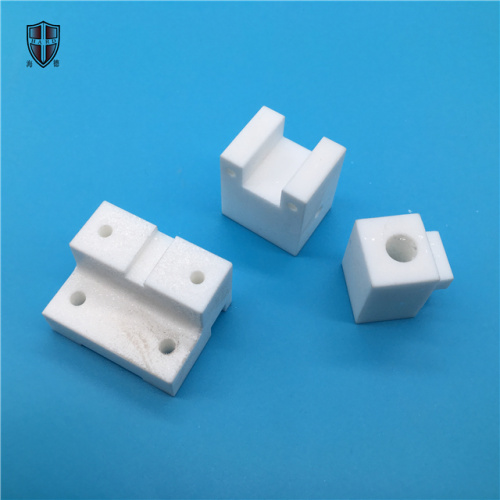

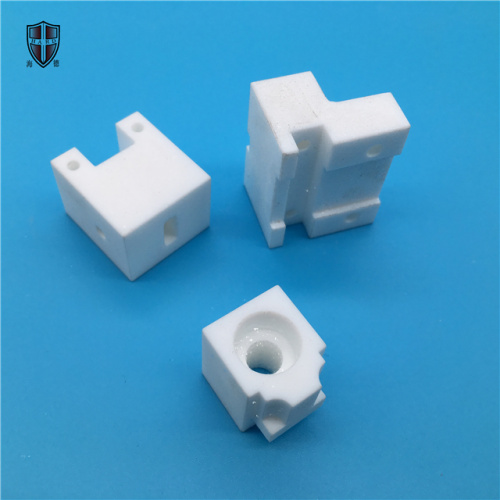

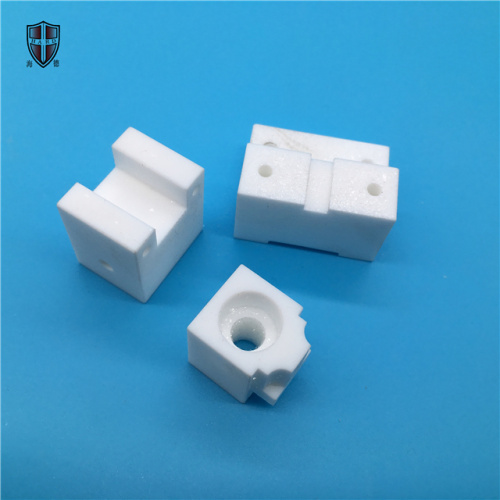

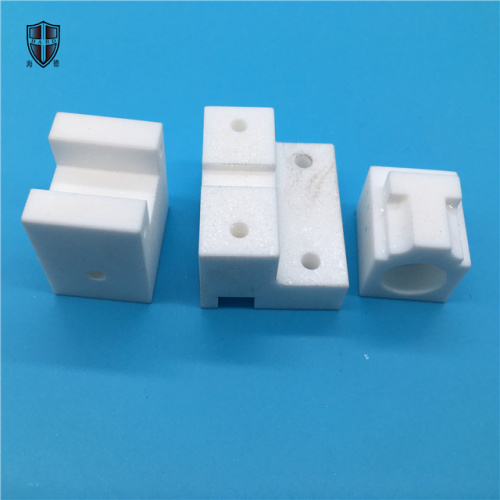

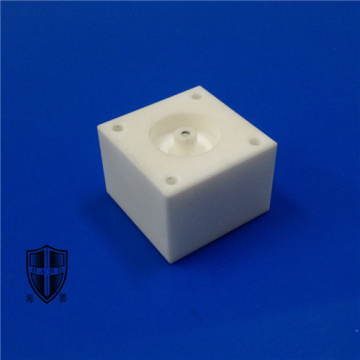

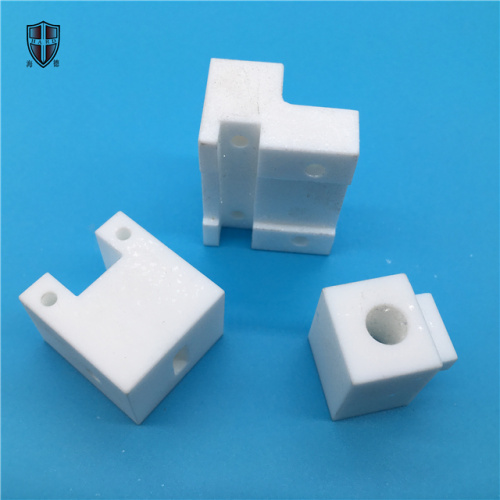

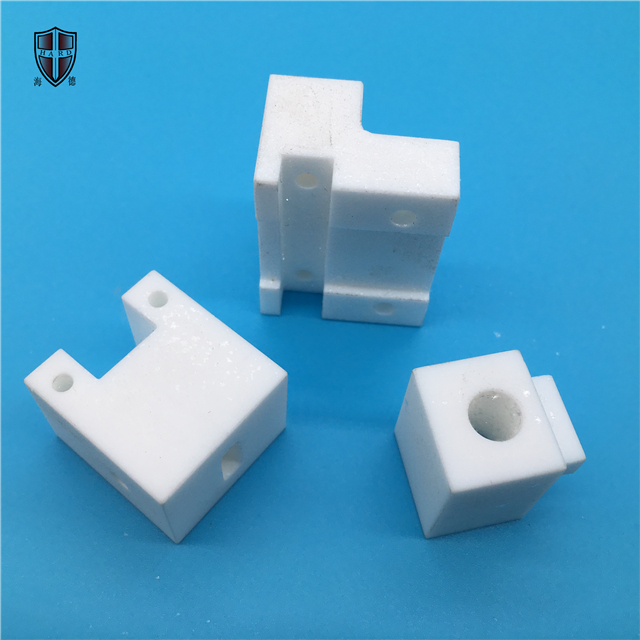

high tolerance machinable mica macor glass ceramic parts

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

high tolerance machinable mica macor glass ceramic parts

Reputation depends on quality, quality comes from Hard!

Macor Glass Machinable Glass Ceramic:

application

(1) β-spodumene glass-ceramics and carbon fiber composites: strong toughening effect, new materials in aerospace.

(2) Oxygen-nitrogen glass-ceramics: Direct microcrystallization can be performed without radiation or addition of crystal nuclei, which lowers the sintering temperature of the silicon nitride crystal and maintains a high-strength β-silicon nitride structure.

(3) Cleaved mica glass-ceramics: layered structure, good electrical insulation and heat resistance (electronic insulating materials)

Production Process

The preparation method of the glass ceramics includes a whole crystallizing method (melting method), a sintering method, a sol-gel method, etc., and the methods currently applied industrially in China are the former two.

(1) Overall crystallization method

1) Forming crystal nucleus in the glass by adding crystal nucleating agent or ultraviolet irradiation

2) After the heat treatment, the crystal nucleus grows up, and other production processes are the same as ordinary glass.

Process: melting and forming, pre-crystallization processing, crystallization heat treatment, processing of glass-ceramics

At present, it is widely used in the cooker of the induction cooker. The concave type microcrystalline glass refers to the glass ceramic which has a concave shape and is similar to the current state of the pot. The main use of the glass-ceramic plate is currently mainly used in high-power commercial induction cookers and household induction cookers. With the increase in gas prices, the cost of the catering industry, and the perception of cooking without open flames, the number of household cookers has increased. Sales of concave glass-ceramics have also increased accordingly.

properties:

Good insulativity, high temperature(800°), good machinable property, can be made of rod and plate in short time.

Data Sheet↓

Color: WhiteDensity: 2.6g/cm3

Gas permeability: 0

Water Absorption: 0

Rockwell Hardness(45N): 40R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 108Mpa

Compressive Strength(20°C): 488Mpa

Modulus of Elasticity(25°C): 65Gpa

Thermal Conductivity(25°C):1.71W(m.K)

Thermal Expansion Coefficient: 7.2 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum Use Temperature: 800°C

Dielectric Strength: >30 KV/mm

Volume Resistivity(20°C): >10(16)Ω.cm

Application industry:

Machinery, electronic, limitary, aerospace etc.

Specific application:

Machined equipment high temperature insulated parts, electronic equipment high temperature insulated parts.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords