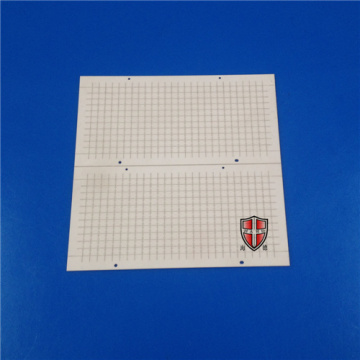

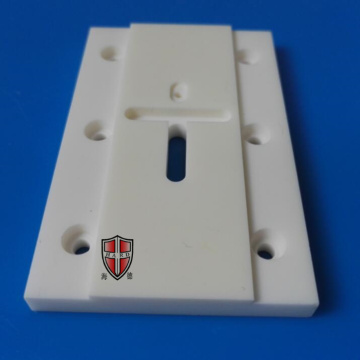

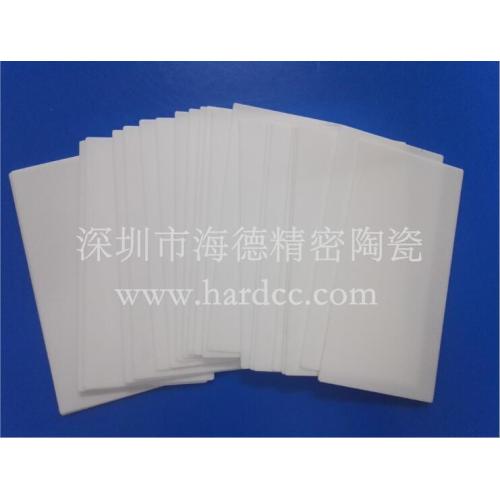

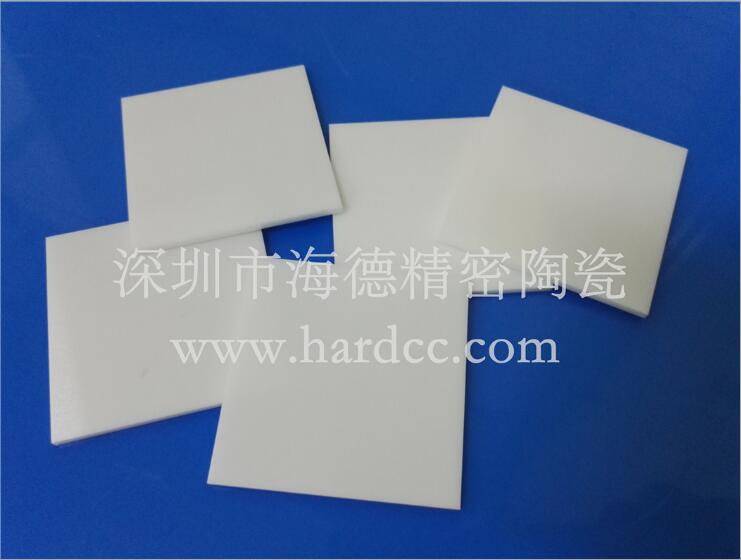

alumina ceramic electronic heat sink sheet substrate

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

alumina ceramic electronic heat sink sheet substrate

Reputation depends on quality, quality comes from Hard!

Ceramic Substrate:

Liquid heat sinks are suitable for high power applications such as laser diodes, data centers, direct cooling power modules, high brightness LEDs or solar arrays (CPV), which are more than four times more efficient than conventional liquid cooling module structures. The aluminum nitride layer plays a role in insulating the circuit of the laser diode from the cooling water channel. Silicon nitride ceramics have many excellent properties such as high hardness, high strength, small thermal expansion coefficient, low temperature creep, good oxidation resistance, good thermal corrosion resistance and low friction coefficient. They are the best structural ceramic materials with comprehensive performance. The theoretical thermal conductivity of single crystal silicon nitride is up to 400 w/(m·K), which has the potential to be a highly thermally conductive substrate. In addition, the linear expansion coefficient of silicon nitride is well matched with semiconductor materials such as Si, SiC and GaAs, which makes silicon nitride ceramics an extremely attractive substrate material for high-strength and high thermal conductivity electronic devices. See the comparison of mechanical properties of silicon nitride, aluminum nitride and alumina ceramics.

Application:

The role of ceramic substrate ceramic substrate according to the field of ceramic substrate application, is divided into HIC (hybrid integrated circuit) ceramic substrate, focusing potentiometer ceramic substrate, laser heating fixing ceramic substrate, chip resistor substrate, Network resistor substrate, etc.; according to different processing methods, ceramic substrates are divided into two types: molded tablets and laser scribe films. The ceramic substrate in the chip resistor substrate is a part of the chip resistor. The upper layer of the substrate is coated with different semiconductor materials, and then copper is plated on both ends for soldering. The biggest advantage of the whole resistor is that the volume can be made very well. small.

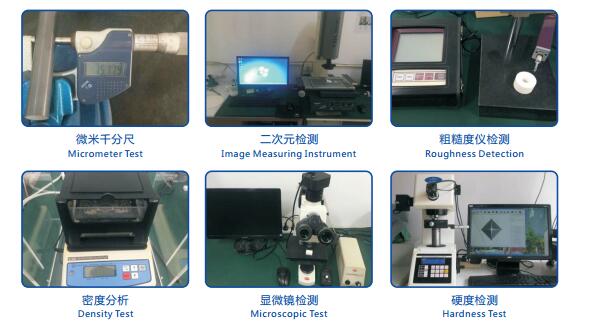

Company Information:

Shenzhen Hard Precision Ceramic CO.,Ltd founded in 2007, located in Shenzhen of China. We are a company that integrates development, design, molding, sintering, production and sales of precision ceramic products. After 10 years of development, we have cooperated with more than 2000 customers and 60 universities; Our factory covers an area of 2000 square meters, 50 employees, and annual production value of nearly 20 million. We have a higher visibility and better reputation in the same industry.Our products include ceramic rods, tubes, plates, blocks and precision parts for industrial. We have all-line high precision equipments from ceramic forming, sintering to precision machining. Hope for a wide range of sincere cooperation with customers at home and abroad.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Show time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

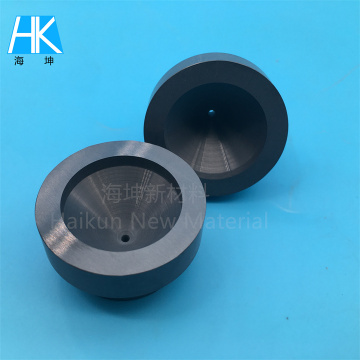

Products Show

Factory Show

Our Team

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords