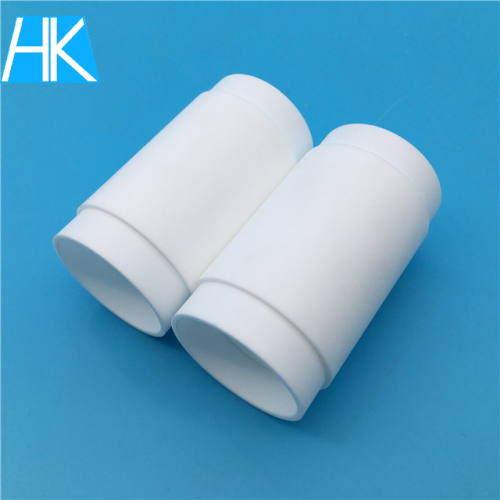

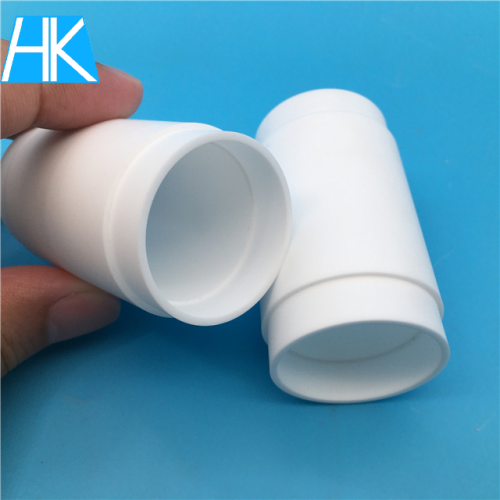

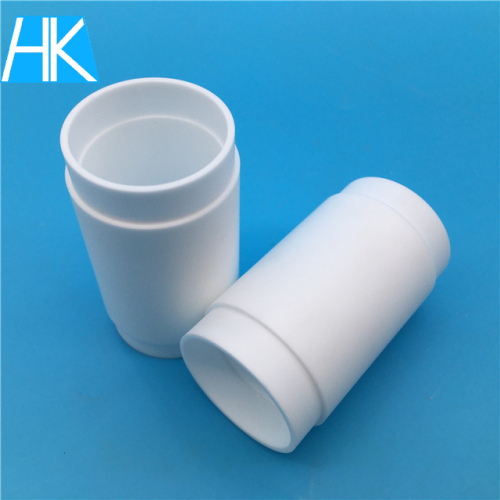

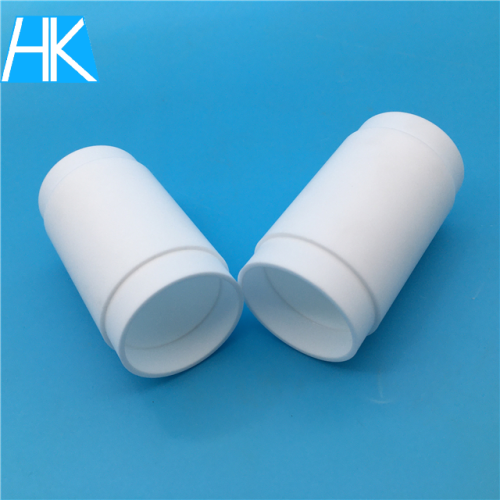

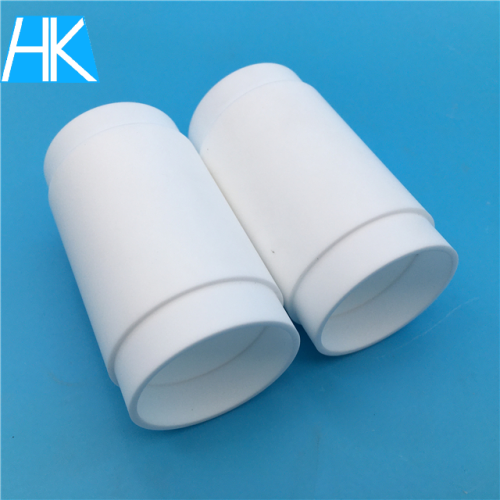

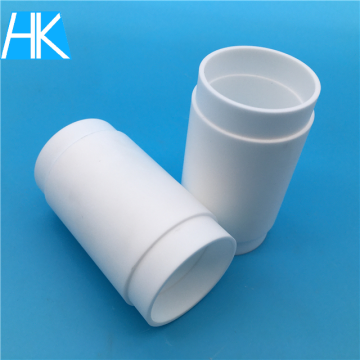

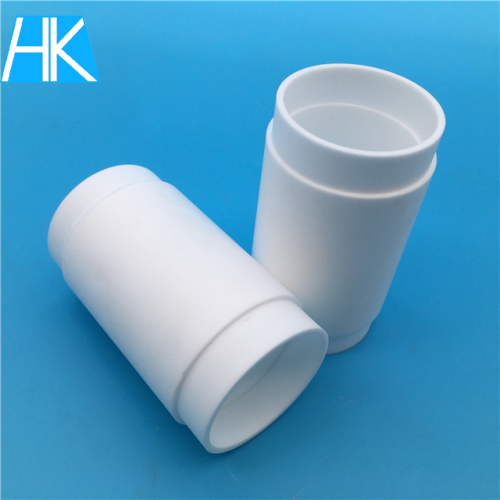

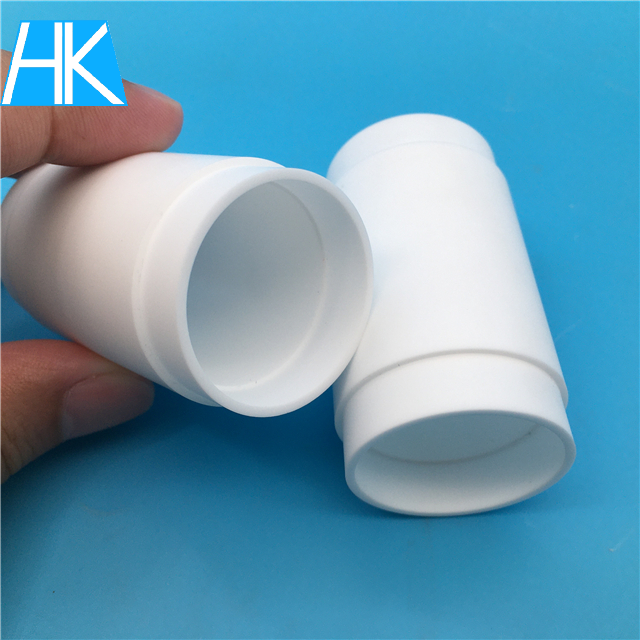

beryllia berillia BeO beryllium oxide ceramic parts

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

beryllia berillia BeO beryllium oxide ceramic parts

Reputation depends on quality, quality comes from Hard!

Zirconia Ceramics:

BeO ceramic products are also a refractory material. BeO ceramic crucible can be used to melt rare metals and precious metals, especially in the occasions requiring high-purity metals or alloys. The working temperature of the crucible can reach 2000°C. Due to its high melting temperature (approximately 2550°C), high chemical stability (alkali resistance), thermal stability and purity, BeO ceramics can also be used to melt uranium and plutonium. In addition, these crucibles have been successfully used to make standard samples of silver, gold and platinum. BeO's high degree of "transparency" to electromagnetic radiation allows the use of induction heating to smelt the metal samples in it.

In avionics technology conversion circuits and aircraft and satellite communication systems, BeO is widely used as bracket components and assembly parts; it also has application prospects in spacecraft electronics. The use of BeO ceramics has particularly high thermal shock resistance, and can be used in the squib of jet aircraft. Metal-coated BeO sheets have been used in the control system of aircraft driving devices; Ford and General Motors have used metal-sprayed beryllium oxide linings in automobile ignition devices [13]. BeO ceramics have good thermal conductivity and are easy to be miniaturized. They have broad application prospects in the laser field. For example, BeO lasers have higher efficiency and higher output power than quartz lasers.

Beryllium oxide ceramics are ceramics with beryllium oxide as the main component. Mainly used as materials for large-scale integrated circuit substrates, high-power gas laser tubes, heat sink shells of transistors, microwave output windows and neutron moderators. Beryllium oxide ceramics have the characteristics of high thermal conductivity, high melting point, high insulation, high chemical and thermal stability, low dielectric constant, low dielectric loss and good process adaptability. It is used in special metallurgy, vacuum electronic technology, nuclear technology, Microelectronics and optoelectronics technology are widely used. Especially in high-power semiconductor devices, integrated circuits, microwave electric vacuum devices and nuclear reactors, BeO is the mainstream ceramic material for preparing high thermal conductivity components.

BeO ceramic products are also a refractory material. BeO ceramic crucible can be used to melt rare metals and precious metals, especially in the occasions requiring high-purity metals or alloys. The working temperature of the crucible can reach 2000°C. Due to its high melting temperature (approximately 2550°C), high chemical stability (alkali resistance), thermal stability and purity, BeO ceramics can also be used to melt uranium and plutonium. In addition, these crucibles have been successfully used to make standard samples of silver, gold and platinum. BeO's high degree of "transparency" to electromagnetic radiation allows the use of induction heating to smelt the metal samples in it.

Data Sheet↓

| Beryllia Ceramic Properties | ||

| Item | Unit | Typical Values |

| Physical Properties | ||

| Color | White | |

| Density | g/cm3 | 2.85 |

| Grain Size | um | 10—20 |

| Gas permeability | cc/sec He | 10-8 |

| Water Absorption | % | 0 |

| Mechanical Properties | ||

| Rockwell 45N | 60 | |

| Flexural Strength(20°C) | Mpa | 200 |

| Tensile Strength | Mpa | 152 |

| Modulus of Elasticity | Gpa | 345 |

| Poisson's Ratio | 0.26 | |

| Fracture Toughness(20°C) | MPam1/2 | 3.5 |

| Thermal Properties | ||

| Thermal Conductivity(100°C) | W(m.K) | 200 |

| Thermal Expansion Coefficient | 10-6/°C | 7.0-8.5 |

| Specific Heat | cal/g°C | 0.25 |

| Electronic Properties | ||

| Dielectric Strength | KV/mm | ≥30 |

| AC Dielectric Strength | V/mil (6.35mm) | 230 |

| Dielectric Constant | 1 MHz (at RT) | 6.6±0.1 |

| Dielectric Constant | 10 GHz (at RT) | 6.9±0.1 |

| Dielectric Loss Angle | 1 MHz (at RT) | ≤4*10-4 |

| Volume Resistivity(25°C) | Ω.cm | ≥1014 |

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords