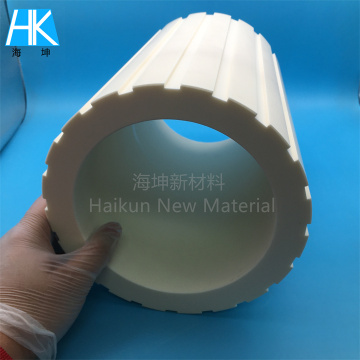

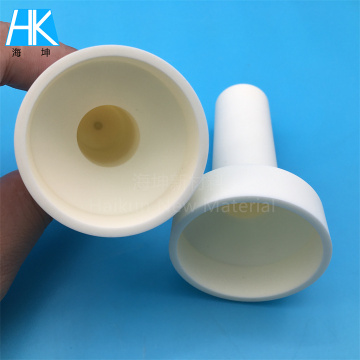

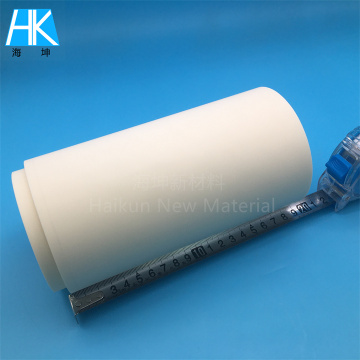

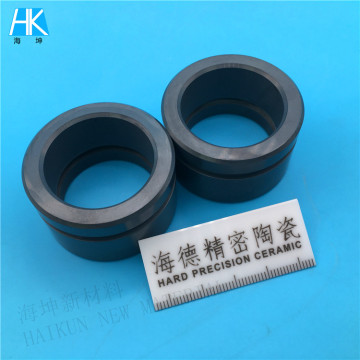

technical alumina ceramic machining drilling tube pipe bush

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

technical alumina ceramic machining drilling tube pipe bush

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

1. Good overall technical alumina ceramic performance, high impact strength, chemical stability, and good electrical properties;

2. It has good weldability with 372 plexiglass, made into two-color plastic parts, and can be chrome-plated and painted;

3. There are high impact resistance, high heat resistance, flame retardant, reinforced, transparent and other levels;

4. The fluidity is slightly worse than HIPS, better than PMMA, PC, etc., and flexibility is good;

5. Suitable for making general mechanical parts, wear-reducing and wear-resistant parts, transmission parts and telecommunication parts.

(2) Forming performance

1. Amorphous material, medium fluidity, high moisture absorption, and must be fully dried. Plastic parts that require gloss on the surface must be preheated and dried for a long time at 80-90 degrees for 3 hours;

2. It is advisable to take high material temperature and high mold temperature, but it is easy to decompose if the material temperature is too high (the decomposition temperature is >270℃). For plastic parts with higher precision, the mold temperature should be 50-60℃; for high-gloss and heat-resistant plastic parts, the mold technical alumina ceramic temperature should be 60-80℃;

3. If you need to solve the water trapping, you need to improve the fluidity of the material, adopt high material temperature, high mold temperature, or change the water level, etc.;

4. If heat-resistant or flame-retardant materials are formed, plastic decomposition products will remain on the surface of the mold after 3-7 days of production, which will cause the surface of the mold to shine, and the mold must be cleaned in time, and the surface of the mold must be vented;

5. The cooling rate is fast. The mold gating system should be thick and short. The cold material cavity should be set, and the gate should be large, such as direct gate, disc gate or fan gate, etc., but internal stress should be prevented If necessary, an adjustable gate can be used. The mold should be heated and wear-resistant steel should be used;

6. The material temperature has a great influence on the quality of plastic parts. If the material temperature is too low, it will cause lack of material, the surface is dull, and the silver wire is disordered.

7. The mold temperature has a great influence on the quality of plastic parts. When the mold temperature is low, the shrinkage, elongation, impact resistance, bending resistance, compression resistance, and tensile strength are low. When the mold temperature exceeds 120℃, the plastic parts will cool slowly, easily deform and stick to the mold, difficult to demold, and the molding cycle is long;

8. The molding shrinkage rate is small, melting cracking technical alumina ceramic is easy to occur, and stress concentration occurs. Therefore, the molding conditions should be strictly controlled during molding, and the plastic parts should be annealed after molding;

9. The melting temperature is high, the viscosity is high, and it is not sensitive to shearing. For plastic parts larger than 200 grams, screw injection machine should be used. The nozzle should be heated. It is appropriate to use an open extension nozzle. The injection speed is medium and high.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords