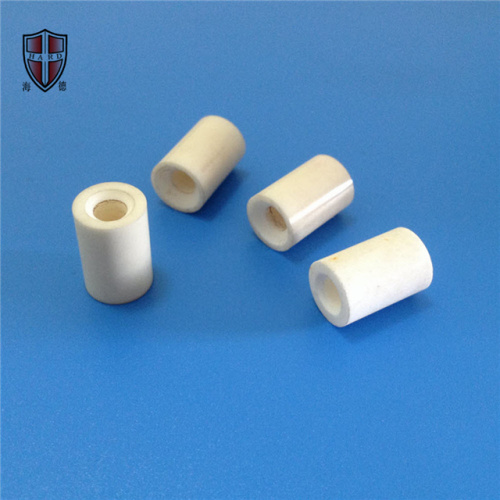

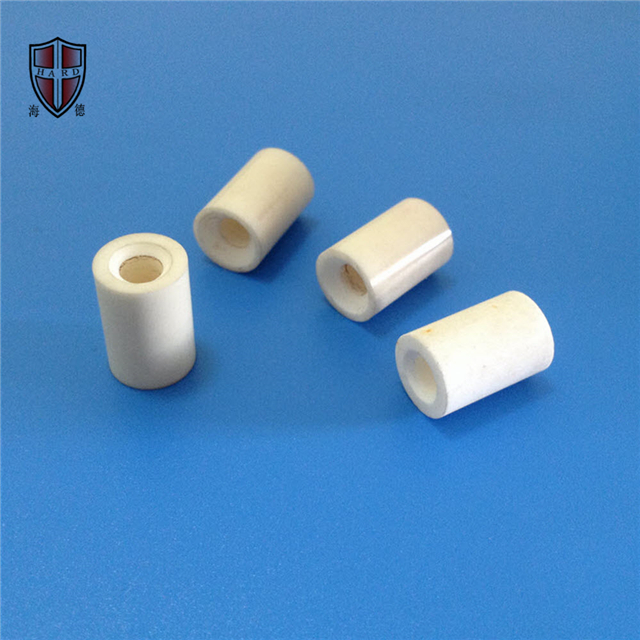

isostatic pressing abrasive alumina ceramic sleeve valve

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

isostatic pressing abrasive alumina ceramic sleeve valve

Reputation depends on quality, quality comes from Hard!

Alumina Ceramic:

There is also a β-Al 2 O 3 which has ion conductivity (allowing Na to pass) and a sodium-sulfur battery made of β-alumina as an electrolyte. Since such a battery has a large amount of electric power per unit weight and can discharge a large current, it has a broad application prospect. The negative electrode of the battery is molten sodium, the positive electrode is sodium polysulfide (Na2Sx), and the electrolyte is β-alumina (sodium ion conductor).

The battery can be used in a temperature range of 620 to 680K, and its storage capacity is 3 to 5 times that of the lead battery. The use of β-Al2O3 ceramics as a separator for the production of brine to produce caustic soda has the characteristics of high purity and low pollution. Alumina is suitable for a variety of wet and dry processes, polishing the rough surface of any workpiece.

It is one of the most economical abrasives. This sharp-edged synthetic abrasive has a hardness second only to diamond, and is especially suitable for use when iron contamination is critical. For the roughest cuts, it can also be made into a pebble shape to handle extremely precise workpieces to achieve extremely low roughness. Due to its high density, sharp, and angular structure, it is one of the fastest cutting abrasives available today.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

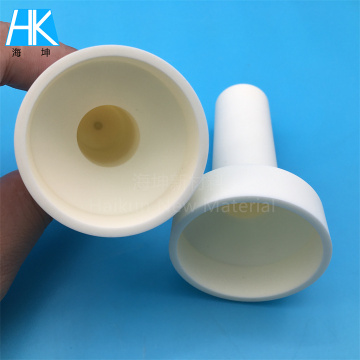

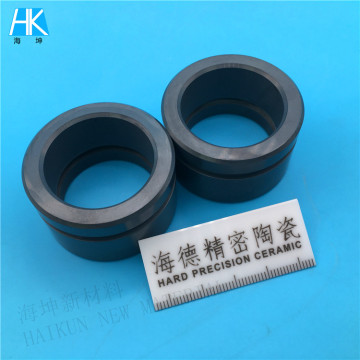

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

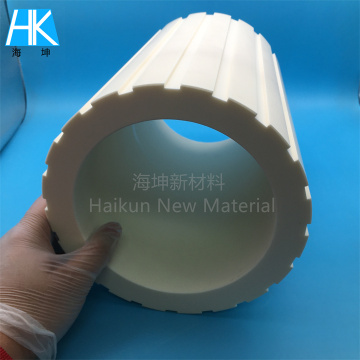

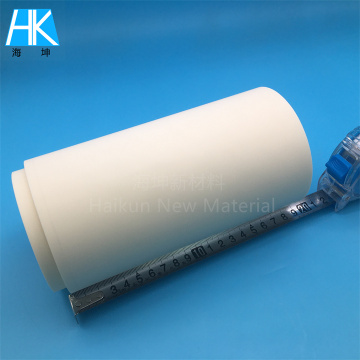

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords