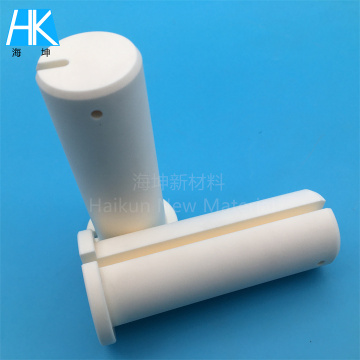

Semi-circular 997% Alumina Ceramic Insulator Heating Plate Assembly

-

$3.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangdong, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal,Alipay |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,CIP,DDP,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangdong,Dongguan |

Semi-circular 99.7% Alumina Ceramic Insulator Heating Plate Assembly

Alumina ceramic insulators and heating plates are commonly used in various industrial applications due to their excellent thermal stability, electrical insulation properties, and chemical resistance.

Alumina Ceramic Insulators:

- Material: Alumina (Al₂O₃) is a high-purity aluminum oxide ceramic.

- alumina ceramic insulator heating plate Properties:

- High mechanical strength.

- Excellent electrical insulation.

- Good thermal shock resistance.

- Chemically inert.

- **Applications**:

- Electrical components.

- High-temperature furnaces and kilns.

- Insulation in high-voltage systems.

- Semiconductor manufacturing equipment.

Different Shape Heating Plates:

Heating plates made from alumina ceramics can be used for applications where both heating and insulation are required. These plates are often designed with heating elements embedded within or attached to the ceramic material.

Design:

- Heating elements (such as resistive wires or films) are typically embedded into the ceramic structure.

- The ceramic provides insulation while allowing efficient heat transfer.

-Alumina Ceramic Insulator Heating Plate Properties:

- Uniform heating distribution.

- High temperature resistance.

- Long service life.

- Easy to clean and maintain.

Applications:

- Industrial drying ovens.

- Laboratory equipment.

- Semiconductor processing tools.

- Food processing machinery.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

If you need more specific information about a particular application or have questions about designing or sourcing these components, feel free to ask! What’sapp/Wechat: +86-13823242056

Related Keywords