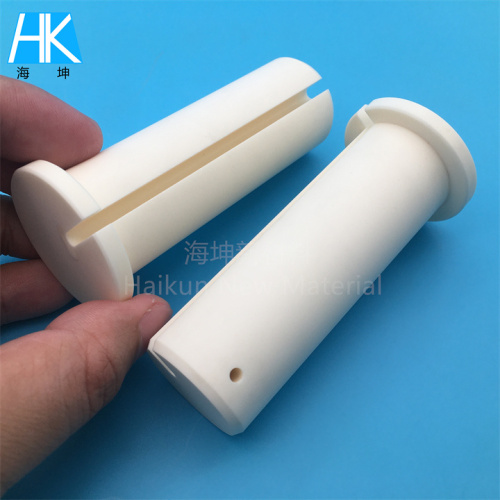

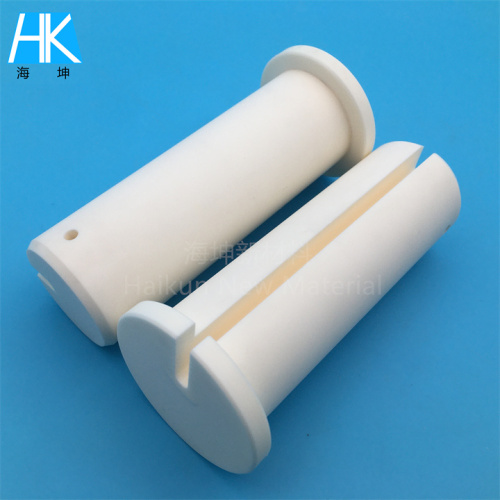

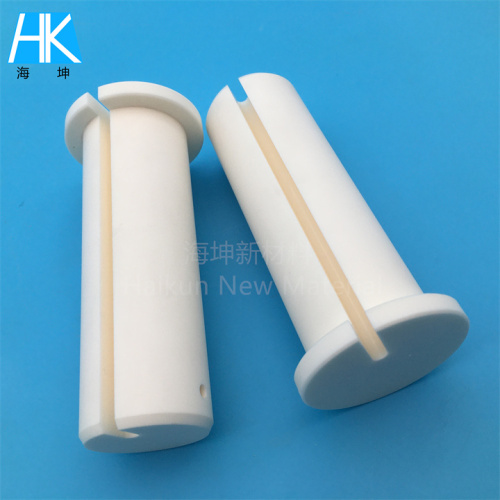

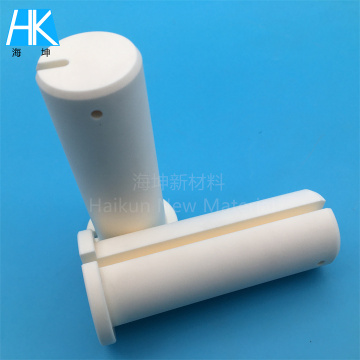

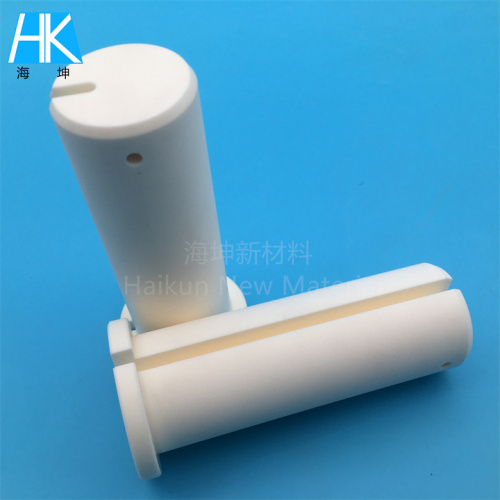

99.5 Alumina Ceramic Structural Insulator Parts

-

$2.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangdong, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,DDU,Express Delivery,EXW,CPT |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangdong,Dongguan |

99.5 Alumina Ceramic Structural Insulator Parts

Alumina ceramic structural insulators, such as those with a specific density of 99.5%, are high-performance materials widely used in various industries due to their excellent thermal insulation properties, electrical insulation properties, and mechanical strength. These characteristics make them ideal for use in applications that require high-temperature resistance, electrical isolation, and robustness.

Here are some key points about these parts:

1. **Composition**: Alumina ceramics are composed primarily of aluminum oxide (Al2O3). The "99.5%" typically refers to the purity of the alumina, meaning that over 99.5% of the material is aluminum oxide.

2. **Thermal Insulation**: Alumina ceramics have high thermal conductivity and are excellent thermal insulators. This makes them suitable for components that need to maintain or regulate temperature effectively, such as in heat exchangers, combustion chambers, and high-temperature sensors.

3. **Electrical Insulation**: They offer high dielectric strength and resistivity, making them ideal for electrical insulating components. They can be used in circuits, transformers, capacitors, and other electrical devices where insulation is critical.

4. **Mechanical Strength**: Alumina ceramics are known for their high strength and durability. They can withstand high mechanical loads and impacts, making them suitable for structural components in machinery, aerospace equipment, and industrial tools.

5. **Corrosion Resistance**: These ceramics are resistant to corrosion from many chemicals and are stable under a wide range of temperatures and environments.

6. **Custom Fabrication**: Alumina ceramic structural insulator parts can often be custom fabricated to meet specific size, shape, and performance requirements.

7. **Applications**: They are used in a variety of applications across different sectors including aerospace, automotive, electronics, energy, medical devices, and more.

If you're looking to purchase or learn more about specific 99.5% alumina ceramic structural insulator parts, pls contact with us and we would be helpful to know the exact dimensions, surface finish requirements, and any other specifications needed for your application. You might consider contacting suppliers or manufacturers who specialize in ceramic materials for more detailed information and assistance.Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years. The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords