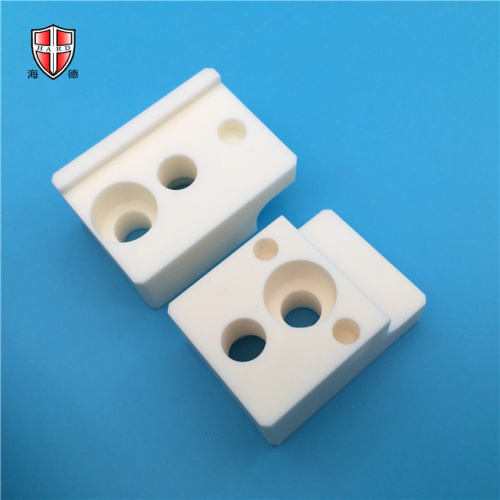

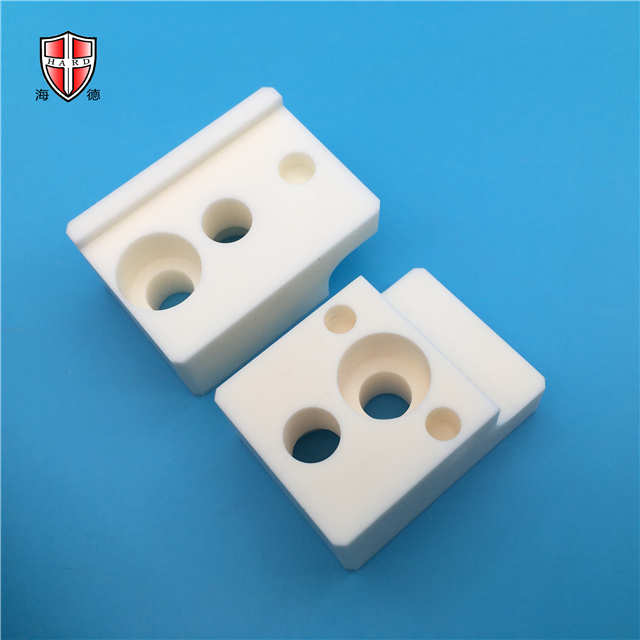

hot pressure casting moulding alumina ceramic block brick

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

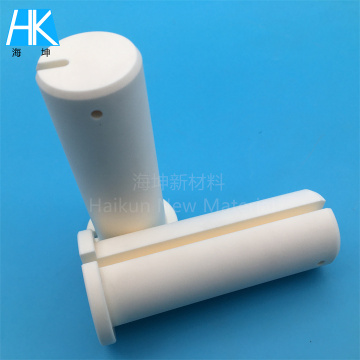

anodic zincous metallized 95 alumina ceramic insulating tube

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

99 alumina ceramic ABS is an amorphous polymer with no obvious melting point. Due to its various grades and grades, appropriate process parameters should be formulated according to different grades in the injection molding process. Generally, it can be molded at a temperature above 160℃ and below 240℃. Because the temperature is too high, there is a tendency to destroy the rubber phase in ABS, and decomposition begins to occur above 250°C. In the molding process, ABS has good thermal stability and a large range of options, and it is not easy to degrade or decompose. In addition, the melt viscosity of ABS is moderate, and its fluidity is better than that of polyvinyl chloride, polycarbonate, etc., and the cooling and solidification speed of the melt is relatively fast, and generally it can be cold-set within 5~15S. The fluidity of ABS is related to injection temperature and injection pressure, and the injection pressure is slightly more sensitive. For this reason, the injection pressure can be used manually during the molding process to reduce the melt viscosity and improve the filling performance. ABS has different water absorption and adhesion properties due to different components. The surface adhesion and water absorption rate is between 0.2~0.5% and sometimes can reach 0.3~0.8%. In order to obtain a more ideal product, it should be made before molding. Drying treatment reduces the water content to below 0.1%. Otherwise, defects such as bubbles and silver threads will appear on the surface of the part.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords