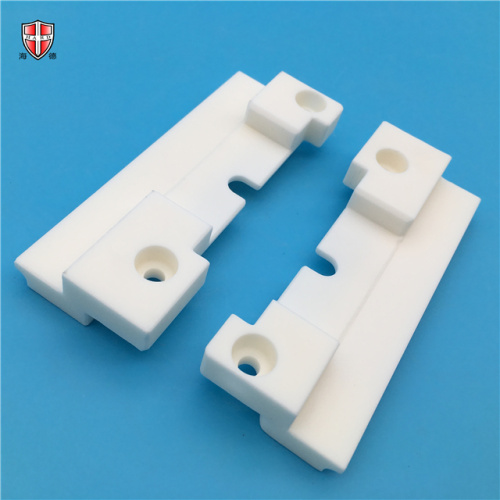

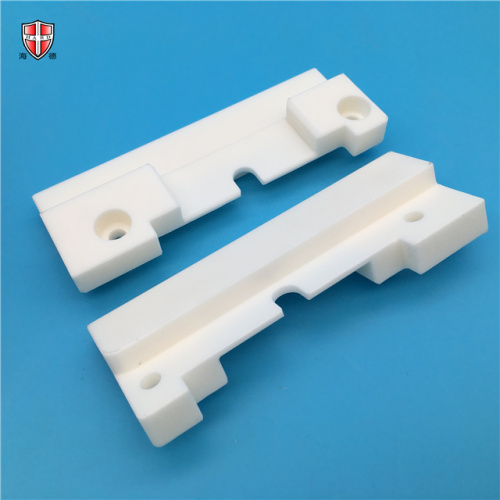

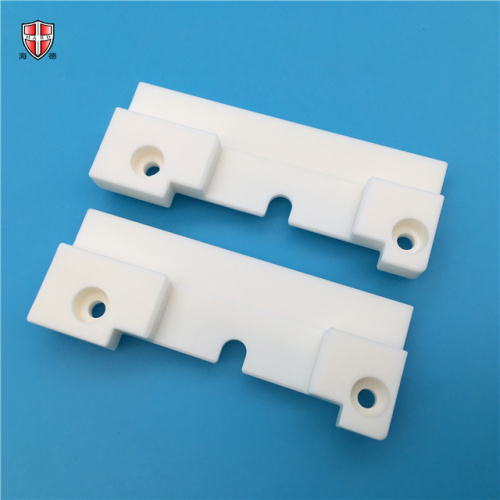

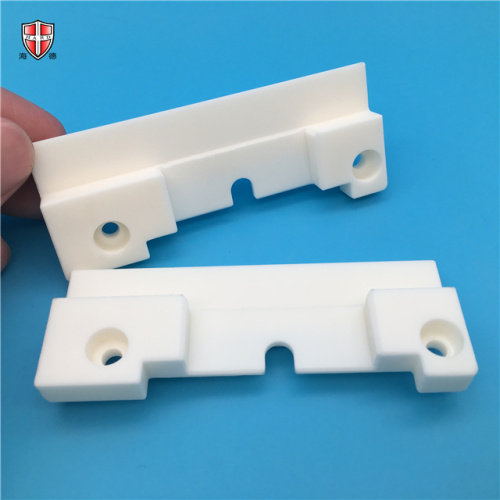

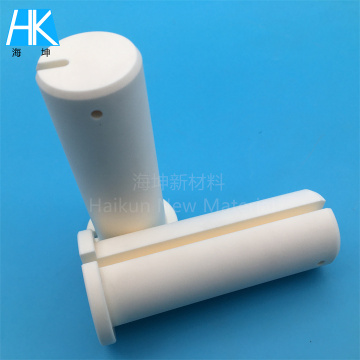

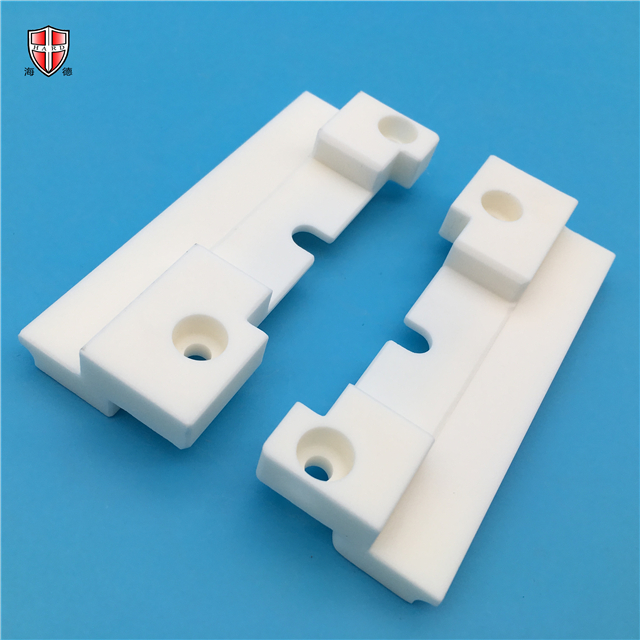

hot isostatic pressure 99 99.5 alumina ceramic parts

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

hot isostatic pressure 99 99.5 alumina ceramic parts

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Zinc oxide is an important raw material for ceramic chemical fluxes, especially in building ceramic wall tile glaze and low-temperature porcelain. It is also widely used in artistic ceramic glaze.

Zinc oxide has a strong fluxing effect in the glaze, which can reduce the expansion coefficient of the glaze and improve the thermal stability of the product. While expanding the melting range, it can increase the glaze of the glaze. However, it should not be used in black glaze containing chromium.

Used as flux: When zinc oxide is used as a solvent in low-temperature frit glaze, the general dosage is between 5% and 10%, and the dosage in low-temperature raw glaze is usually about 5%.

Used as an opacifier: Adding zinc oxide to the glaze containing higher A1203 can improve the opacity of the glaze. Because zinc oxide can produce zinc spinel with A1203, ZnO A1203 crystal, in zinc-containing opalescent glaze, A1203 can improve the whiteness and opacification of the glaze. SIO2 can improve the gloss of the glaze.

Used as a crystallizer: In artistic glaze crystallization, zinc oxide is an indispensable crystallizer. When the melted glaze is rapidly cooled, it forms a large crystal pattern, which is very beautiful. In crystalline glaze, the amount of zinc oxide is as high as 20-30%.

Used to make cobalt sky blue glaze: Zinc oxide is a very important flux in cobalt sky blue glaze. It can make cobalt oxide form beautiful sky blue in glaze.

Used as ceramic pigment: Due to its strong fluxing effect, zinc oxide can be used as a rib flux, mineralizer and glaze carrier for ceramic pigments.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords