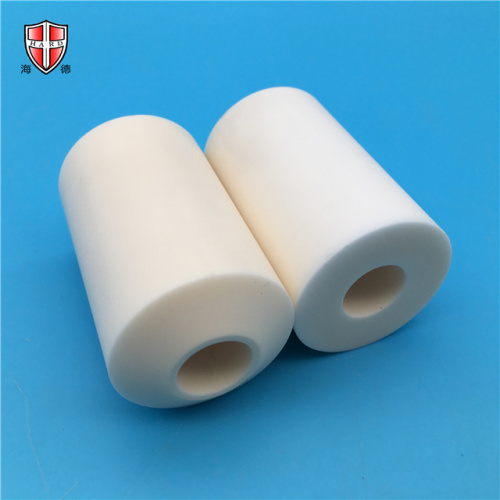

high temperature 99 al2o3 alumina custom ceramic bush

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

refractory 99% alumina ceramic protection bushes sleeves

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramics were synthesized by British ICI Company in 1922. In 1933, British Benemen Chemical Industry Company discovered that ethylene can be polymerized to form polyethylene under high pressure. This method was industrialized in 1939 and is commonly known as the high-pressure method. In 1953, K. Ziegler of the Federal Republic of Germany discovered that with TiCl4-Al(C2H5)3 as a catalyst, ethylene can also be polymerized under lower pressure. This method was put into industrial production by the Federal German Hearst Company in 1955 and is commonly known as low-pressure polyethylene. In the early 1950s, the Phillips Petroleum Company of the United States discovered that ethylene could be polymerized to produce high-density polyethylene under medium pressure using chromium oxide-silica-alumina as a catalyst, and industrial production was realized in 1957. In the 1960s, DuPont of Canada began to manufacture low-density polyethylene with ethylene and α-olefin solution method. In 1977, Union Carbide and The Dow Chemical Company Electrical Insulator Cordierite Ceramic used low-pressure methods to make low-density polyethylene, called linear low-density polyethylene. Among them, the gas phase method of Union Carbide is the most important. The performance of linear low-density polyethylene is similar to that of low-density polyethylene, but it also has several characteristics of high-density polyethylene. In addition, it has low energy consumption in production, so it has developed extremely rapidly and has become one of the most eye-catching new synthetic resins. The core technology of the low pressure method is the catalyst. The TiCl4-Al(C2H5)3 system invented by Ziegler in Germany is the first-generation catalyst for polyolefins, with low catalytic efficiency, about several kilograms of polyethylene per gram of titanium. In 1963, Solvay in Belgium pioneered the second-generation catalyst with magnesium compounds as the carrier, with a catalytic efficiency of tens of thousands to hundreds of thousands of grams of polyethylene per gram of titanium. The second-generation catalyst can also save the post-treatment process of removing catalyst residues. Later, high-efficiency catalysts for gas phase method were developed. In 1975, Italy's Monte Edison Group developed a catalyst that can directly produce spherical polyethylene without granulation. It is called the third-generation catalyst, which is another revolution in high-density polyethylene production.

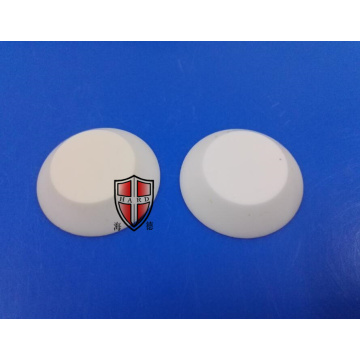

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords