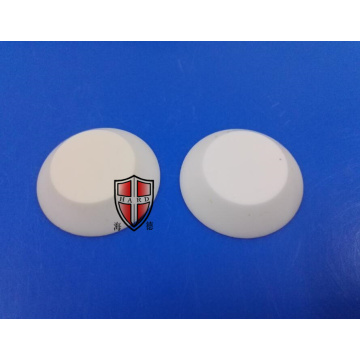

fiber optical polished precision alumina ceramic ferrule

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

fiber optical polished precision alumina ceramic ferrule

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Making convex tires Also known as mother molds, convex tires are made from concave tires. It generally includes a bottom mold and a mold circumference or a core and a mold circumference. Step 5: Making a working mold The convex tyre is turned over and used for grouting. 2 Mold material and classification (1) Traditional casting gypsum moldThe manufacturing process: the standard β-type semi-water gypsum powder is added with water to make a gypsum slurry, which is stirred And vacuum degassing, etc., injected into the master mold, after the gypsum hardens, it is demolded, and then properly trimmed, assembled, and dried at 50-60 ° C for 5-7 days. (2) Plaster for low-pressure fast drainage casting There are two types of molds with and without microporous pipe network. The gypsum mold with microporous pipe network is different from the previous one mainly: before pouring, it must be in the corresponding part of the master mold (2 away from the pouring working surface Centimeters), put into the shaped pipe network, the interface of these pipe networks can be connected to the vacuum and compressed air pipelines on the forming line, in order to drain water, mold release and mold dehydration during pouring. Materials are: microporous glass fiber hose, pipe diameter φ = 7.5mm; nylon wire for braided mesh φ = 9.5um: resin impregnating solution for mesh (based on resin, catalyst (Initiator, talc, etc.). These braided materials are braided into a pipe network in another specially made auxiliary master mold and cured. After being removed from the mold, it is used to make a master mold. The gypsum used is β- Gypsum or α-gypsum. The latter is 1 times higher in flexural strength than the former; the surface micro-hardness is 60% higher, and the tensile strength is about 2 times higher. However, the standard consistency water absorption is about 30% lower. -Gypsum is more suitable for making high-strength plaster models.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords