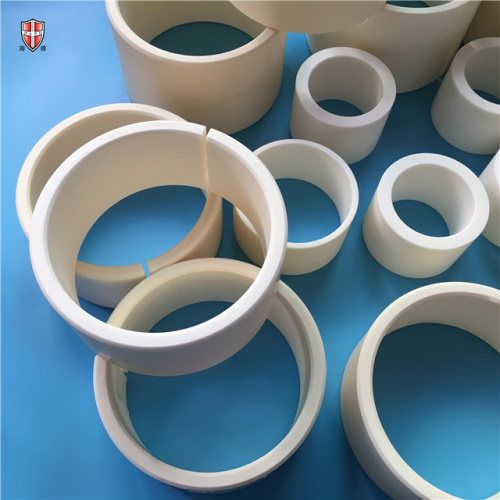

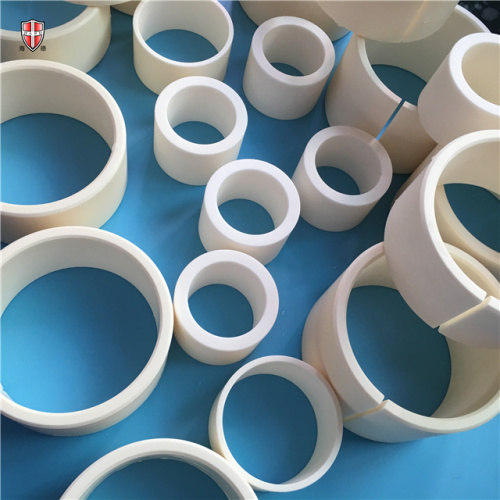

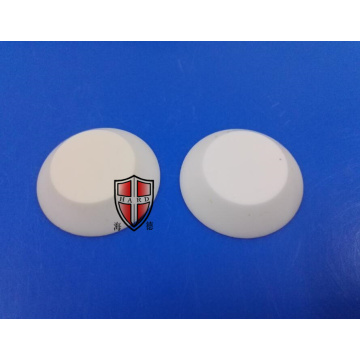

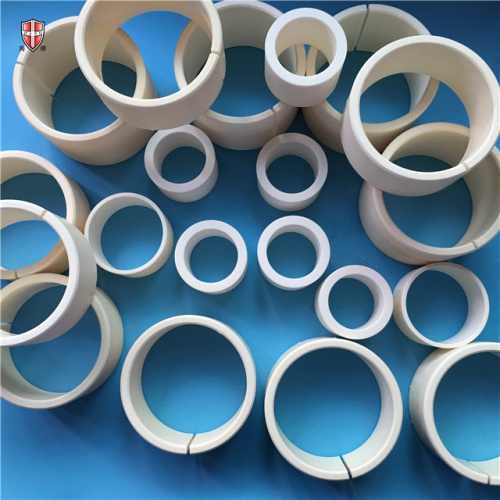

refractory insulating alumina ceramic bush sleeve

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

refractory insulating alumina ceramic bush sleeve

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramics are atomic crystals and are diamond-like nitrides that are stable to 2200 ° C. The room temperature is high and the strength decreases slowly with increasing temperature. It has good thermal conductivity and small thermal expansion coefficient, and is a good thermal shock resistant material. It has strong ability to resist molten metal erosion and is an ideal tantalum material for casting pure iron, aluminum or aluminum alloy. Aluminum nitride is also an electrical insulator with good dielectric properties and is also promising for use as an electrical component. Due to the characteristics of the aluminum nitride piezoelectric effect, the epitaxial stretching of the aluminum nitride crystal is also used for the surface acoustic wave detector. Aluminum nitride is used in optoelectronic engineering, including optical storage interfaces and electronic substrates as electrical layers, chip carriers for high thermal conductivity, and military applications. Ultra-fine aluminum nitride powder is mainly used as a thermal conductive filler for polymer materials. It is a very good, high thermal conductivity insulating filler. It has a wide application prospect in electronic glue, thermal conductive plastic, LED heat dissipation and heat transfer. At present, the application of aluminum nitride powder in the thermal conductivity of polymer materials is not optimistic, mainly when the customer uses the theoretical heat transfer heat transfer effect is too far from the actual test data. For this main reason, aluminum nitride powder is a material that easily absorbs moisture and oxygen. When it comes into contact with moisture and oxygen, it is hydrolyzed and oxidized. As a result, it loses its thermal and thermal properties. This is currently limiting nitrogen. A major problem in the use of aluminum powder. The aluminum nitride ultrafine powder, which has not been surface treated and modified, is difficult to be uniformly mixed with the polymer material, so that it is difficult to form a good heat conduction channel and interpenetrating network, and it is difficult to solve the heat conduction and heat transfer of the polymer.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords