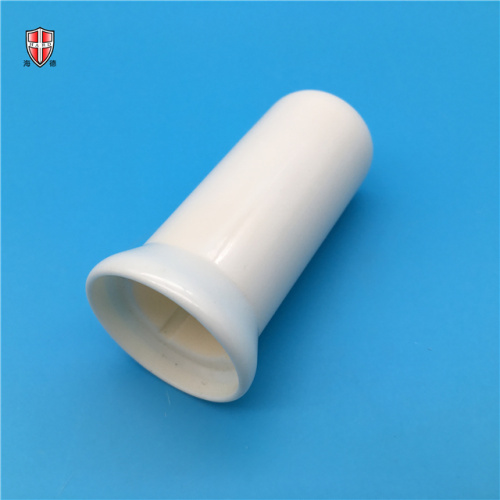

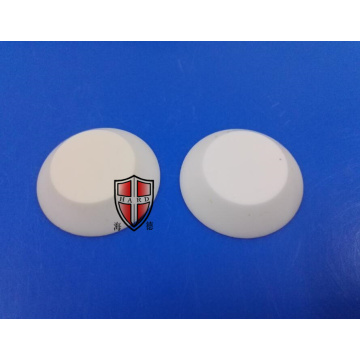

custom made insulating glaze alumina ceramic parts

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

custom made insulating glaze alumina ceramic parts

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramic material is a lightweight and efficient thermal insulation material. Compared with traditional thermal insulation materials, it has the following advantages:

a. Low bulk density: The ceramic fiber lining is lighter than the light insulation brick lining by more than 75%, which is 90% to 95% lighter than the lightweight castable lining. If the fiber lining is used, the steel structure load of the kiln can be greatly reduced, and the service life of the furnace body can be prolonged.

b. Low heat capacity (heat storage): The heat capacity of the ceramic fiber is only about 1/10 of that of the lightweight heat-resistant lining and the lightweight castable lining, and the heat capacity of the lining material is proportional to the weight of the lining. The low heat capacity has a very significant energy saving effect on the start and stop of the heating furnace.

c. High thermal conductivity: The thermal conductivity of the ceramic fiber lining is 1/10 of the lightweight heat-resistant lining, and the thermal conductivity is remarkable.

d. Simple construction: no expansion joints need to be left in the construction process, and the construction personnel can be employed after basic training.

e. Excellent thermal shock resistance and mechanical vibration performance: The fiber blanket and module have flexibility and elasticity. Under the premise of being able to withstand the heating body, the fiber folding module lining can be heated or cooled at any fast speed and is not easily damaged.

f. No need for oven: After the lining is completed, it can be put into use without the need of oven program.

g. Sound insulation performance: ceramic fiber has high frequency noise with frequency less than 1000 Hz. For sound waves less than 300HZ, the sound insulation ability is better than that of common sound insulation materials, which can significantly reduce noise pollution.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords