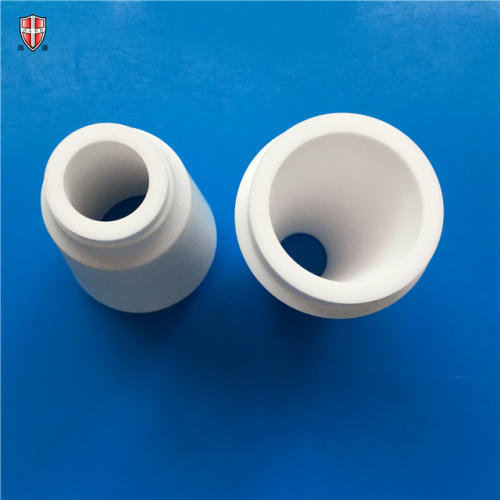

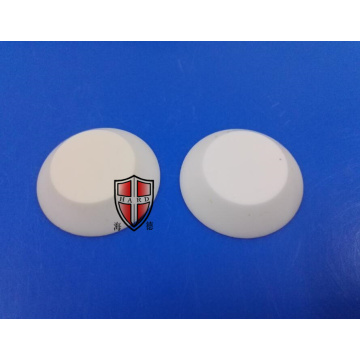

high thermal conductivity alumina white ceramic tube bush

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

high thermal conductivity alumina white ceramic tube bush

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The alumina ceramic centrifugal casting composite pipe is a composite pipe manufactured by "self-grown high-temperature synthesis-high-speed centrifugal technology", which forms a uniform, dense and smooth surface ceramic layer and transition layer at high temperature and high speed. The working temperature is 850-900 degrees. The ceramics will not fall, the weight is lighter, and the composite ceramics are wear-resistant and hard to solve the problem. In the past, the thickness is anti-wear. Straight pipes, elbows, elbows, tees, etc. are very good in the wear and tear industry. The ceramic pipe is made of high temperature and strong adhesive to paste the alumina ceramic piece on the inner wall of the pipe. After heating and solidification, it forms a firm anti-friction layer. The manufacturing process is simple and the cost is high. The use temperature can not exceed 100 degrees, which is not suitable for pipes. The spot-welding type wear-resistant ceramic pipe is to adhere the intermediate-pored alumina ceramic piece to the inner wall of the pipe with high temperature resistant strong adhesive, and at the same time, the spot welding process is used to firmly weld the ceramic to the inner wall of the steel pipe through the small hole. Protect the solder joints and screw on the ceramic caps. Each tile is not only intertwined with each other, but each porcelain forms a trapezoidal angle, which makes the ceramic blocks tightly connected without gaps; when the last piece of a circle is tightly embedded , porcelain block A 360° mechanical self-locking force is formed (this technique was applied to Chinese bridge construction projects centuries ago). Rivet connection, metal needs to be penetrated by a magnetic drill or drill, and then rivets It is connected with the cross-pressure type perforated ceramic sheet and metal. The production process of this kind of product is relatively complicated, the production cycle is longer and the cost is higher.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords