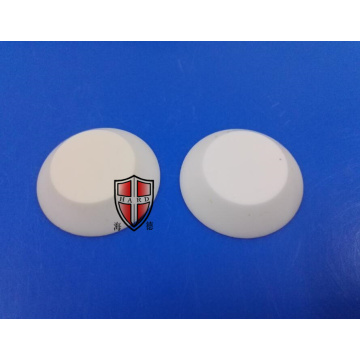

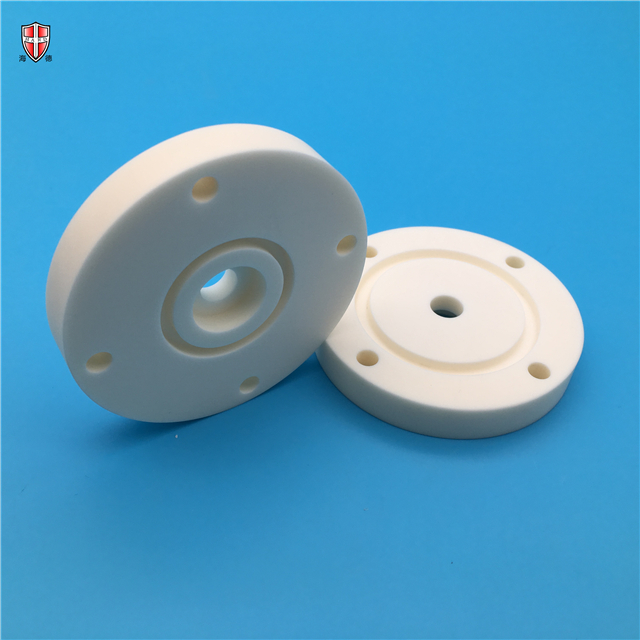

wear resistant pure alumina ceramic plate disc customized

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

wear resistant pure alumina ceramic plate disc customized

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramic crucible Kim Min

Gold is also a precious metal and is highly resistant to corrosion, but its low melting point (1063 ° C) limits its use. The molten alkali metal hydroxide does not erode gold, and it is preferable to use such a gold for melting.

Gu Shi

Note: Gold will melt when heated on a high temperature gas lamp (must never touch gold with aqua regia)

Jubilee

Silver is cheaper than gold, it is also not attacked by potassium hydroxide or sodium, and acts only slightly near the edge of the air in the molten state. However, the melting point of silver is 960 ° C, which cannot be directly heated on the fire. After the silver is heated, a layer of silver oxide is formed on the surface. The silver oxide is unstable at high temperatures and stable below 200 ° C. Silver easily reacts with sulfur to form silver sulfide. It is not allowed to decompose and burn sulfur-containing substances in silver crucibles. Alkaline vulcanization flux is not allowed. In the molten state, metal salts such as aluminum, zinc, tin, lead, and mercury can make the silver enamel brittle. Silver enamel can not be used to melt borax. When leaching the molten material, acid should not be used. In particular, the concentrated acid should not be contacted. The mass of silver ruthenium will change after burning, so it is not suitable for weighing. The original cold-rolling equipment passed the optimized reduction procedure (reducing the number of rolling passes). At the same time, the production increased by 276%, showing the potential for energy saving. It is estimated that in the hot strip production of alumina strip, this energy saving potential will not be small; in the existing hot rolling reduction procedure, the number of passes n is reduced by 2 to 4 aluminum hooks, and the feasibility is very large. To optimize the hot-rolled aluminum sheet with the pressure reduction procedure, firstly, the temperature drop of each hot rolling of the hot rolling should be solved; otherwise, it will not be possible to check whether the full rolling pressure of each rolling of the hot rolling meets the optimal constraints.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords