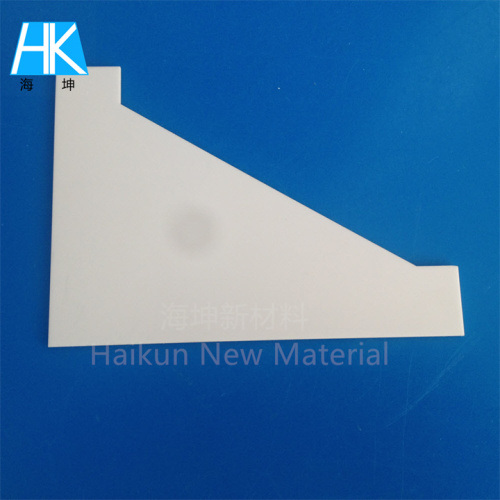

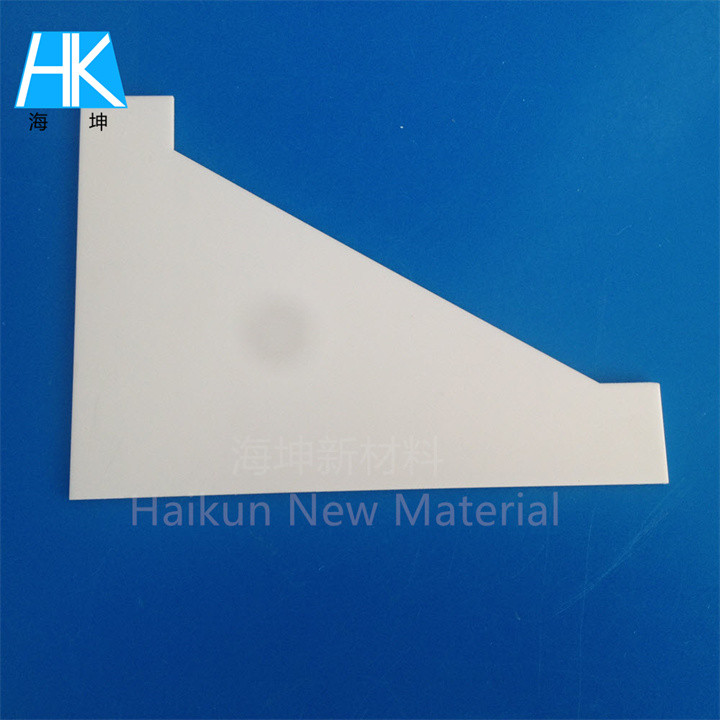

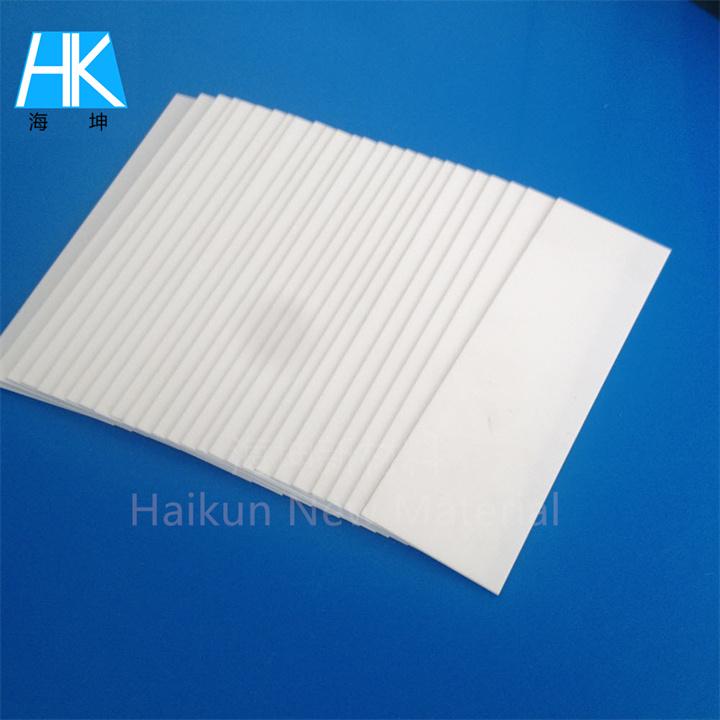

Ultra-thin 96% Alumina Ceramic 1mm Plate Substrate

-

$1.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs |

| Supply Ability: | 10000000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Dongguan |

Insulating Alumina Ceramic Substrate Plate Sheet

An ultra-thin 96% alumina ceramic plate substrate is a specialized material that is highly prized for its unique properties and applications in various high-tech industries. The key characteristics of such a substrate include:

1. **High Thermal Conductivity**: Alumina ceramics have a high thermal conductivity, which makes them ideal for use in applications where heat dissipation is crucial, such as in electronic devices or high-power semiconductor components.

2. **High Electrical Insulation**: These substrates offer excellent electrical insulation properties, which are essential for preventing electrical shorts and ensuring the safety and reliability of electronic circuits.

3. **High Mechanical Strength**: They are known for their high resistance to mechanical stress and wear, making them suitable for use in environments where durability is critical.

4. **Ultra-Thinness**: The term "ultra-thin" suggests that these substrates are designed to be very thin, which can enhance their flexibility and compatibility with other materials, especially in applications requiring compact designs.

5. **High Temperature Stability**: Alumina ceramics can withstand high temperatures without degrading, which makes them suitable for use in high-temperature applications, such as in aerospace or automotive components.

6. **Precision Manufacturing**: Given their critical role in many applications, ultra-thin 96% alumina ceramic substrates often require precise manufacturing techniques to ensure uniform thickness, surface finish, and dimensional accuracy.

**Applications**:

- **Semiconductor Packaging**: Used in the packaging of integrated circuits to improve heat dissipation and electrical insulation.

- **Electronics**: As circuit boards or heat sinks in high-performance electronics like servers, laptops, and smartphones.

- **Optics**: In laser and optical systems where high thermal stability and precision are required.

- **Aerospace**: Components that need to withstand extreme temperatures and maintain structural integrity.

- **Energy**: In power conversion and storage systems, particularly in renewable energy technologies where efficient heat management is critical.

The choice of an ultra-thin 96% alumina ceramic plate substrate depends on the specific requirements of the application, including the desired level of thermal conductivity, electrical insulation, mechanical strength, and temperature stability, along with considerations for cost and manufacturing feasibility.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

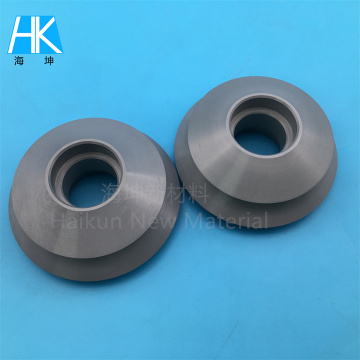

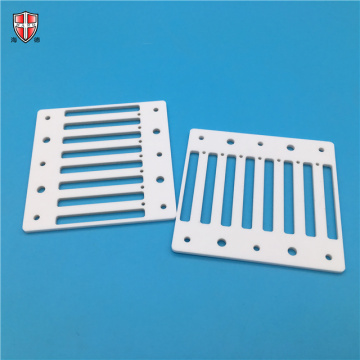

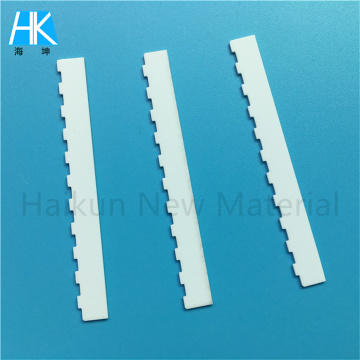

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords