96% Al2O3 aluminum oxide ceramic laser cutting sheets

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

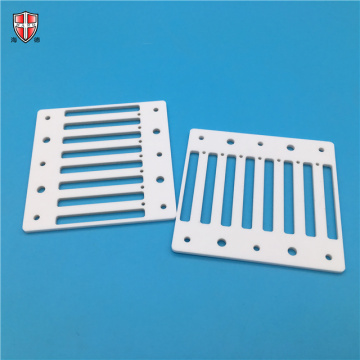

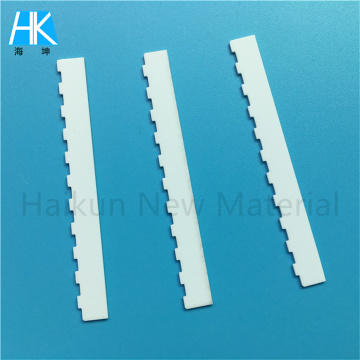

96% Al2O3 aluminum oxide ceramic laser cutting sheets

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The polycarbonate used in the alumina ceramic industry is mainly synthesized from bisphenol A and phosgene. Its main chain contains a benzene ring and four-substituted quaternary carbon atoms, which increases rigidity and heat resistance. Tm=265-270℃, Tg= At 149℃, it can maintain good mechanical properties at 15-130℃. It has excellent impact resistance and transparency, stable dimensions, creep resistance, and performance better than polyester. It is an important engineering plastic. However, polycarbonate is prone to stress cracking and hydrolysis when heated, so it should be fully dried before processing.

The preparation methods of polycarbonate include transesterification method and direct phosgene method. The principle is similar to the transesterification method for producing polyester polyester. Bisphenol A and diphenyl carbonate melt polycondensation, carry out transesterification, continuously eliminate phenol under high temperature and reduced pressure conditions, and increase the degree of reaction and molecular weight.

The transesterification method needs a catalyst and is carried out in two stages: the first stage, the temperature is 180-200℃, the pressure is 270-400Pa, the reaction is 1-3h, the conversion rate is 80%-90%; the second stage, 290-300℃ , Below 130Pa, deepen the degree of reaction. The starting diphenyl carbonate should be excessive. After transesterification, the phenol is discharged. The phenol discharge is used to adjust the ratio of the two groups and control the molecular weight. Phenol has a high boiling point, and it is not easy to remove it from a high-viscosity melt. Compared with polyester polyester, polycarbonate has a much higher melt viscosity, such as a molecular weight of 30,000 and a viscosity of 600 Pa·s at 300°C, which requires higher mixing and heat transfer of reaction equipment. Therefore, the molecular weight of the transesterification polycarbonate is limited, and it does not exceed 30,000.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

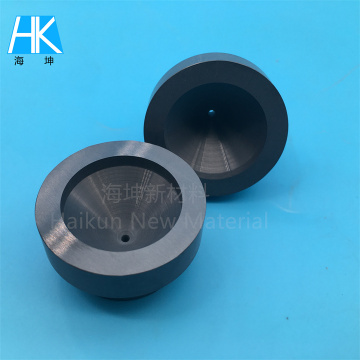

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords