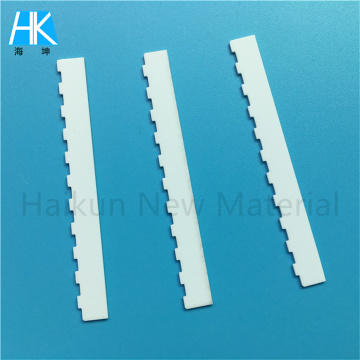

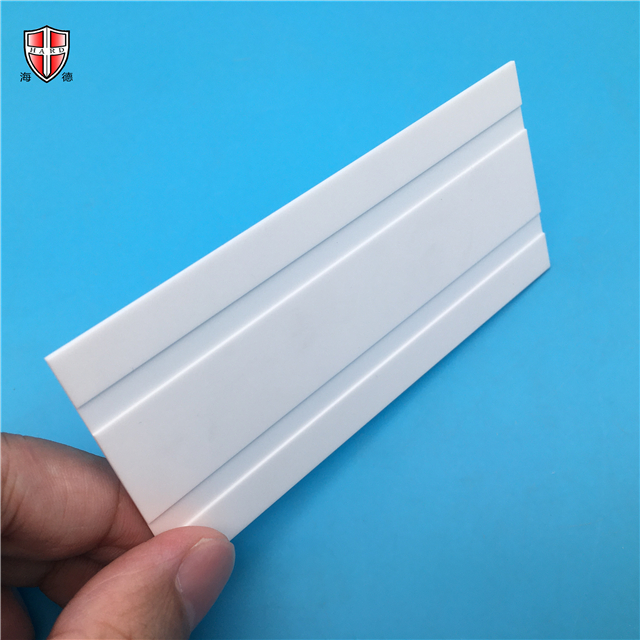

electronic 96% alumina ceramic shell fixture guide

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

electronic 96% alumina ceramic shell fixture guide

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramic polycarbonate sheet has good light transmittance, impact resistance, resistance to ultraviolet radiation and its dimensional stability and good molding and processing performance, making it more obvious than the traditional inorganic glass used in the construction industry. Advantage. China has built more than 20 production lines for polycarbonate building materials hollow board, and the annual demand for polycarbonate is about 70,000 tons, which will reach 140,000 tons by 2005. Polycarbonate has good impact resistance, thermal distortion resistance, good weather resistance and high hardness, so it is suitable for the production of various parts of cars and light trucks. It is mainly concentrated in lighting systems, instrument panels, heating panels, and Frostware and bumpers made of polycarbonate alloy. According to data from developed countries, the proportion of polycarbonate used in the electrical and electronic and automobile manufacturing industries is 40%-50%, and the proportion of China's use in this field is only about 10%. The electrical and electronic and automobile manufacturing industries are the pillars of China’s rapid development. Industry, the demand for polycarbonate in these fields will be huge in the future. The total number of automobiles in China is large and the demand is large, so the application of polycarbonate in this field has great potential for expansion. Because polycarbonate products can withstand steam, cleaning agents, heating and high-dose radiation sterilization without yellowing and physical performance degradation, they are widely used in artificial kidney hemodialysis equipment and other devices that need to be operated under transparent and intuitive conditions. In medical equipment that requires repeated disinfection. Such as the production of high-pressure syringes, surgical masks, disposable dental appliances, blood separators, etc.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

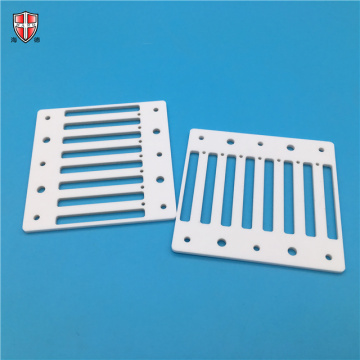

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

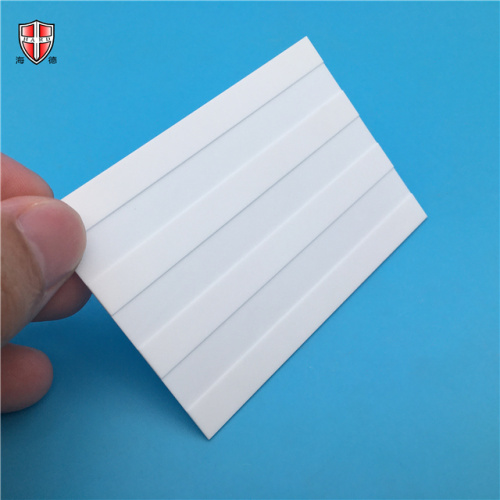

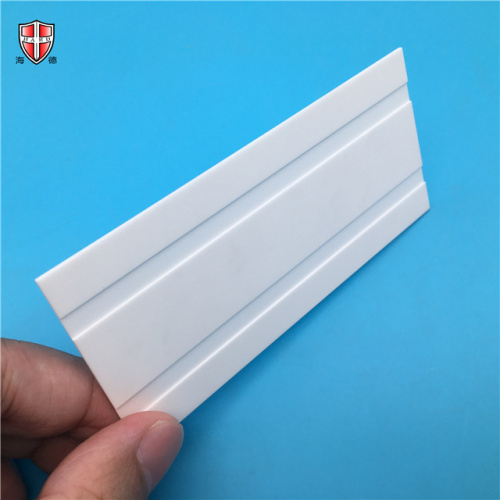

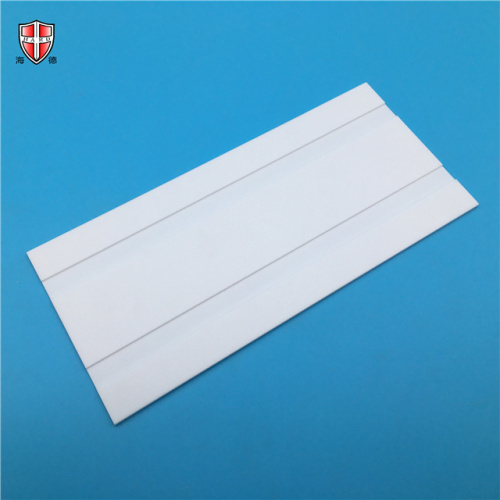

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords