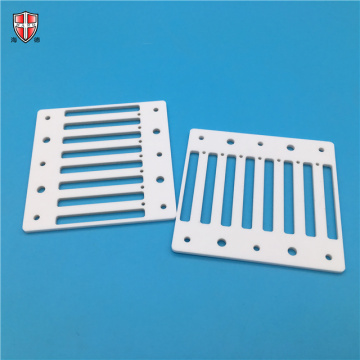

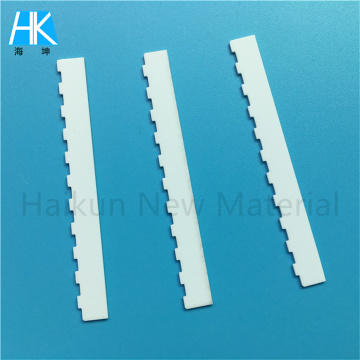

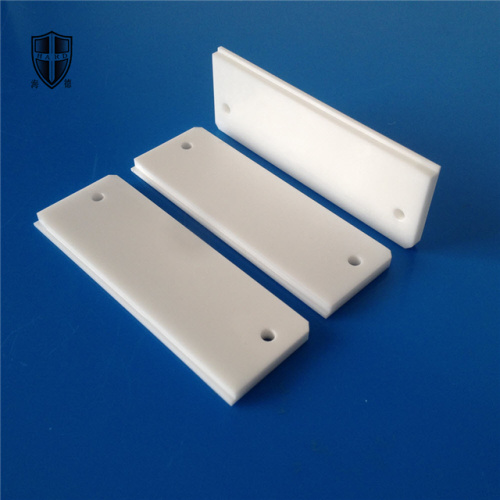

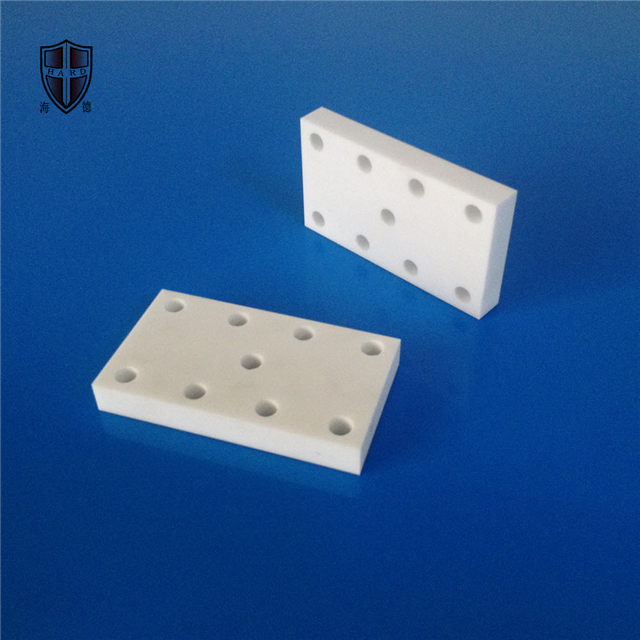

abrasive alumina Al2O3 ceramic brick plate with holes

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

abrasive alumina Al2O3 ceramic brick plate with holes

Reputation depends on quality, quality comes from Hard!

Alumina Ceramic:

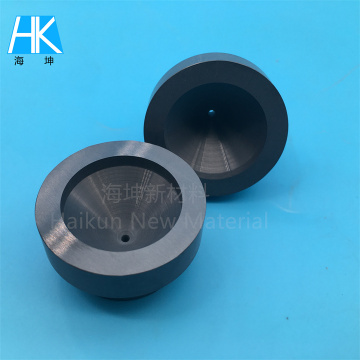

Adhesive anti-wear ceramic sheet

Adhesive anti-wear ceramic sheet. It is composed of a wear-resistant shaped ceramic piece with a dovetail groove and a metal fixed plate with a tapered section. The fixing plate is welded on the blade working surface, and the anti-wear shaped ceramic piece is affixed to the fixing plate to be integrated with the workpiece (blade). The utility model has the unique concept and good wear resistance, ensures that the ceramic piece does not fall off the block, and greatly prolongs the service life. It is an ideal set-adhesive anti-wear ceramic piece for the coal powder fan blade of the thermal power plant.

Porous infrared ceramic sheet

The porous infrared ceramic piece is provided with a porous infrared ceramic piece, characterized in that: an annular convex surface (3) is arranged on the upper end surface (1) of the ceramic piece, and the advantage of the utility model is that the annular convex surface (3) plays The function of the ribs improves the mechanical strength of the infrared ceramic sheet, which can reduce the bursting phenomenon; increases the surface area of the infrared ceramic sheet and increases the heat load; the combustion flame is not at the same horizontal line, and the wind resistance performance at low fire is improved. The infrared radiation release angle can be released upward from the past plane, and becomes a dual release of focusing and dispersion, which improves the thermal efficiency of the burner, is not easy to temper, and is applicable to a wider range of gas sources.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords