aluminum oxide ceramic substrate wafer disc custom made

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

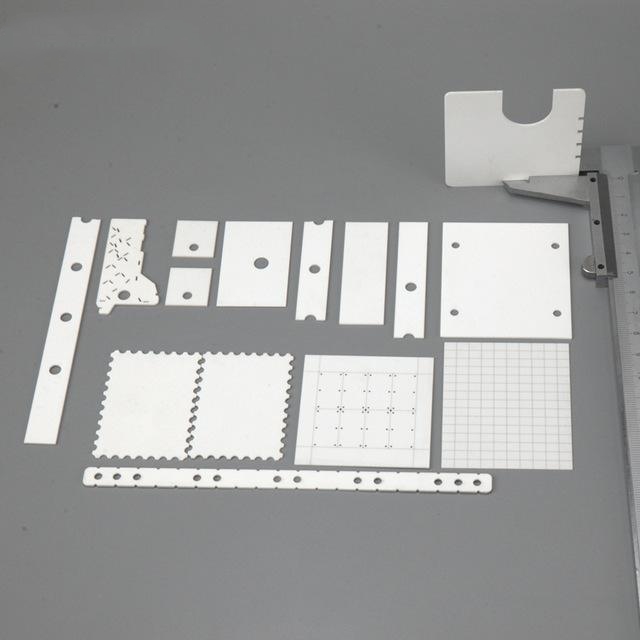

Aluminum oxide ceramic substrate wafer disc custom made

Reputation depends on quality, quality comes from Hard!

Alumina ceramic, a famouse engineering material, is known for its exceptional hardness, wear resistance, and thermal stability. This durability ensures that our discs maintain their dimensional accuracy and performance over time, even under heavy loads and harsh operating conditions. The round alumina disk structural design provides a robust and reliable platform for various applications, while the alumina zirconia ceramic composition offers enhanced strength and fracture toughness.

In the crystal lattice of α-type alumina, the oxygen ions are hexagonally packed tightly, and Al3+ is symmetrically distributed in the octahedral coordination center surrounded by oxygen ions. The lattice energy is large, so the melting point and boiling point are very high. Alpha-type alumina is insoluble in water and acid. It is also called aluminum oxide in industry. It is the basic raw material for making metal aluminum. It is also used in making various refractory bricks, refractory enamel, refractory tubes, high temperature resistant experimental instruments, and as an abrasive. , flame retardants, fillers, etc.; high-purity α-alumina is also the raw material for the production of artificial corundum, artificial ruby and sapphire; also used to produce the board base of modern large-scale integrated circuits.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Density: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): 9.0 MPam1/2

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry: Machinery, electronic, chemical, petroleum etc.

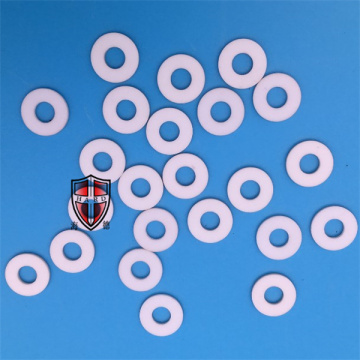

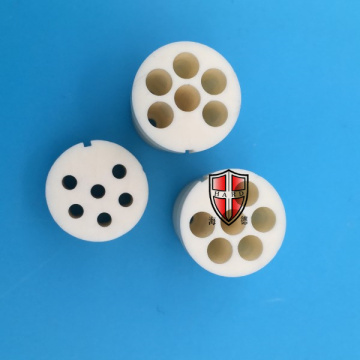

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Company Information:

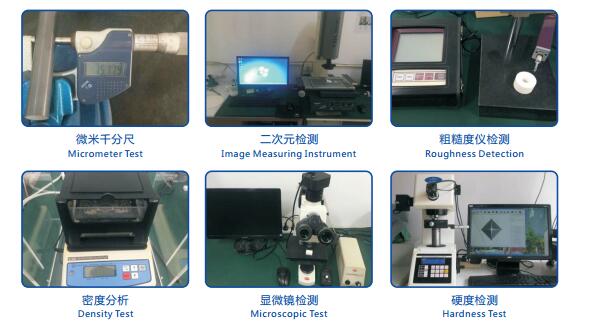

Shenzhen Hard Precision Ceramic CO.,Ltd founded in 2007, located in Shenzhen of China. We are a company that integrates development, design, molding, sintering, production and sales of precision ceramic products. After 10 years of development, we have cooperated with more than 2000 customers and 60 universities; Our factory covers an area of 2000 square meters, 50 employees, and annual production value of nearly 20 million. We have a higher visibility and better reputation in the same industry.Our products include ceramic rods, tubes, plates, blocks and precision parts for industrial. We have all-line high precision equipments from ceramic forming, sintering to precision machining. Hope for a wide range of sincere cooperation with customers at home and abroad.

Products Show

Factory Show

Our Team

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords