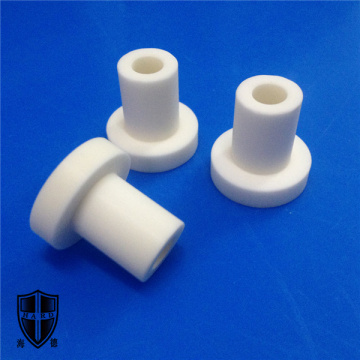

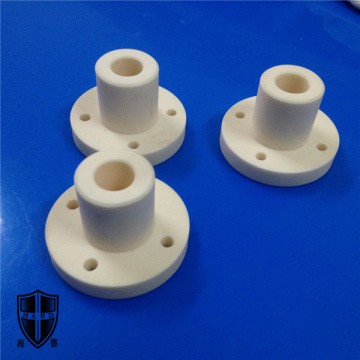

deburring grinding punching 99% alumina ceramic disc disk

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

deburring grinding punching 99% alumina ceramic disc disk

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The moisture content of the ceramic body is generally between 5% and 25%. The combination of the body and the moisture, the changes in the material during the drying process, and the factors affecting the drying rate are the theories to analyze and improve the dryer. Basis. When the body is in contact with stationary air of a certain temperature and humidity, it is bound to release or absorb water, so that the water content of the body reaches a certain equilibrium value. As long as the state of the air is unchanged, the water content reached in the body is No longer changes due to the increase in contact time, this value is the equilibrium moisture of the body in this air state. The moisture lost to the wet body reaching the equilibrium moisture is free moisture. That is, the body moisture is the equilibrium moisture and Free moisture composition. Under certain air conditions, the limit of drying is to make the body reach equilibrium moisture. The water contained in the body can be divided into physical water and chemical water. The drying process only involves physical water, and physical water is divided into combined water. And unbound water. Unbound water exists in the large capillaries of the body, and it is loosely combined with the body. The evaporation of unbound water in the body is like the evaporation of water on the free surface, and the partial pressure of water vapor on the surface of the body The force is equal to the partial pressure of saturated water vapor at its surface temperature. When the unbound water in the body is discharged. The particles of the material are close to each other, so the volume shrinkage occurs, so the unbound water is also called shrinkage water. The bound water is present in the billet. The water in the body's microcapillary (diameter less than 0.1 μm) and the surface of the colloidal particles is more firmly bound to the green body (physical and chemical action), so when the combined water is discharged, the partial pressure of water vapor on the green body surface will be less than the green body. Partial pressure of saturated water vapor at surface temperature. When the partial pressure of water vapor on the surface of the body is equal to the partial pressure of water vapor in the surrounding drying medium during the drying process, the drying process is stopped and the water cannot continue to be discharged. At this time, the body contains The moisture content is the equilibrium water, which is part of the combined water, and its amount depends on the temperature and relative humidity of the drying medium.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords