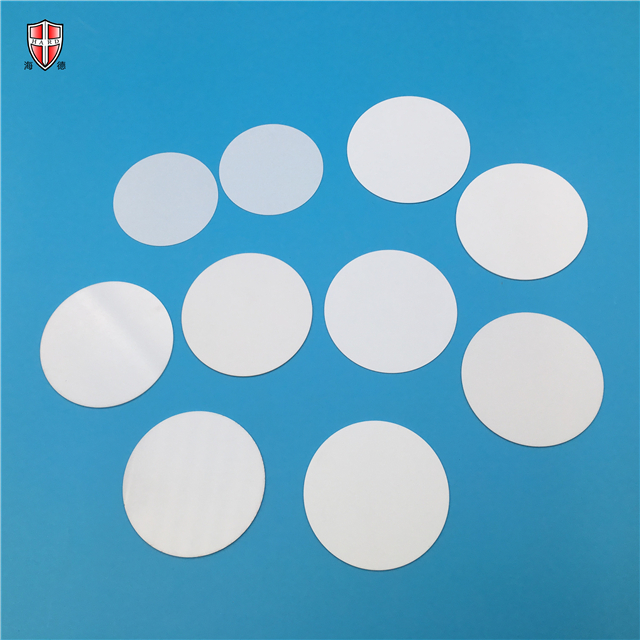

laser cutting 96% alumina zirconia ceramic wafer chip

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

laser cutting 96% alumina zirconia ceramic wafer chip

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina pottery and porcelain are daily necessities that people often come into contact with, sometimes they are similar on the surface, but after all, they have their own characteristics and are different.

Pottery is generally made of clay. The temperature of firing pottery is generally between 900 and 1050 ° C. If the temperature is too high, the pottery will be burnt and deformed. The texture of the pottery of the pottery is relatively loose, and there are many pores, so it has strong water absorption. The surface of ordinary pottery is unglazed, even with glaze, it is low temperature glaze.

The history of China's firing pottery is about 10,000 years. In the primitive society, pottery was first made into a certain shape by hand kneading. Later, it was developed to knead the clay into the same thickness of clay sticks. Then, the clay sticks were shaped into a certain shape, and the inside and outside were smoothed by hand . By the time of the patrilineal society, the rotation method appeared. After entering the feudal society, the molding method was invented, that is, the clay was filled into the mold and the full shape of the utensil was taken out. It has been speculated that the most primitive method of firing was the pile-and-fire method, where dried terracotta slabs were burned in open firewood. Six to seven thousand years ago, pottery was fired in pottery kiln.

Archeologists of cultural relics divide pottery into red, gray, pottery, white, painted, black and glazed pottery according to the color of pottery.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

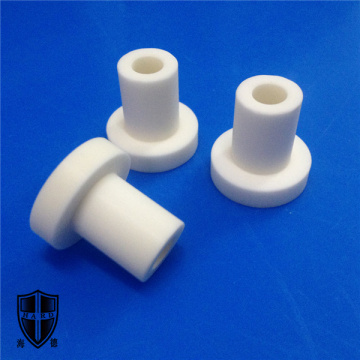

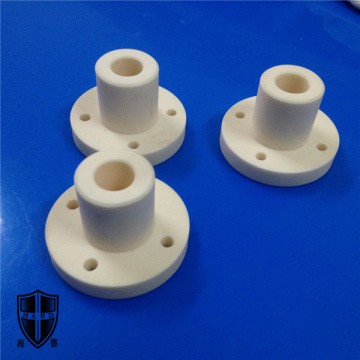

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

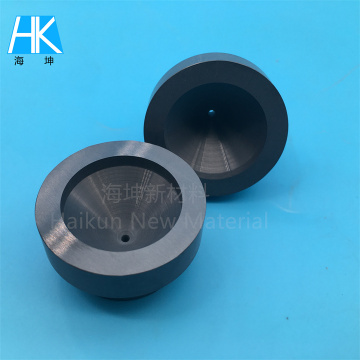

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords