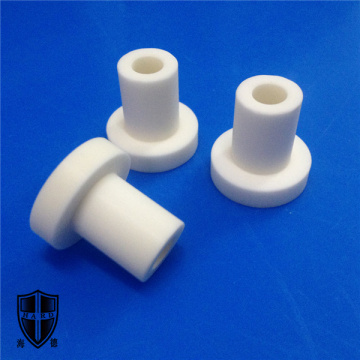

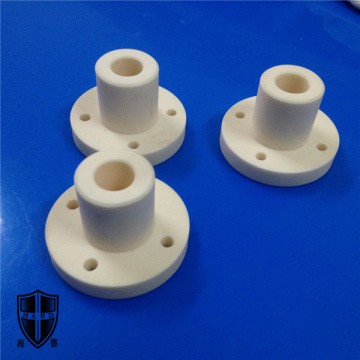

single polished 99% alumina ceramic disc with holes

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

single polished 99% alumina ceramic disc with holes

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

As far as the microscopic morphology of alumina is concerned, whether it is calcined alumina or vapor phase alumina, the difference is not large, and it is irregularly granular, but the particle size has a certain difference. In fact, there are many factors in the polishing process of the metal mirror that restrict the effect of mirror polishing, such as the processing technology, the use environment, and the like. The polishing products currently seen on the market are divided into three forms, solid polishing strips, fluid polishing slurries, and aqueous polishing liquids. These three types of polishing products face the same technical problem, namely the dispersion of alumina powder in the product. In general, the finer the alumina powder particles, the larger the specific surface area, the easier it is to agglomerate, which brings a relatively large test to the production of polishing products. It is common practice to add a certain amount of dispersant to achieve the purpose of dispersion through the potential blocking effect, but all have little effect, because even if the alumina abrasive is dispersed by the potential blocking effect, the abrasive itself will settle and re-agglomerate under the action of gravity. , thus affecting the use effect. Therefore, in order to improve the dispersibility of alumina, some companies have developed high-dispersion polishing alumina powder for mirror polishing of metal. Compared with traditional granular or flake alumina, spherical alumina has better Dispersibility, mobility. The particles can be evenly distributed in the polished product without abnormal powder accumulation. In addition, in order to meet the requirements of metal mirror polishing, some manufacturers will deliberately reduce the size of the original crystal particles of the powder. Experiments have shown that alumina powder with a crystal size of less than 0.03 μm is very suitable for mirror polishing of metal.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords