roll casting polishing alumina ceramic textile spinning coil

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

roll casting polishing alumina ceramic textile spinning coil

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Industrial ceramics mainly produce advanced ceramics such as zirconia ceramics, alumina ceramics, silicon carbide ceramics, silicon nitride ceramics; high temperature kiln furniture is special for lithium battery positive and negative materials, corundum crucible, corundum crucible, corundum bearing Plate, ultra-fine alumina corundum bearing board, cordierite composite mullite push board, silicon carbide shed board, zirconia series of bearing board and other products; industrial kiln to produce experimental electric furnace series, high temperature single (double) channel push Plate kiln, roller kiln, atmosphere protection (kiln) furnace, box furnace, molybdenum wire furnace, mesh belt furnace, bell furnace, vacuum furnace, lifting furnace, trolley kiln and so on.

For example, capacitor ceramics are used to make high-capacity ceramic capacitors with their high electrical breakdown resistance; thermal ceramics can sense small temperature changes for temperature measurement and temperature control; gas-sensitive components made of gas-sensitive ceramics can be easily Burning, explosive, and harmful gases are monitored, controlled, and automatically alarmed; resistors made of photosensitive ceramics can be used for photoelectric control, automatic exposure, and automatic counting; magnetic ceramics are important information recording materials in computers. Complete the memory function. With the development of materials science and the improvement of manufacturing processes, the internal structure of ceramics has become more refined and densified, which has greatly improved the material properties, resulting in new special functions.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

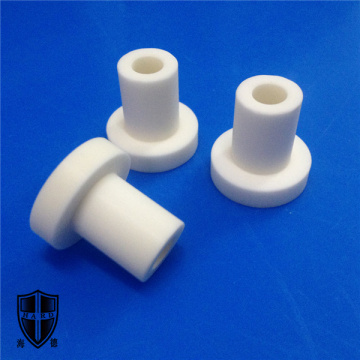

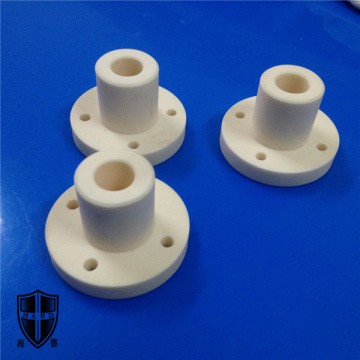

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

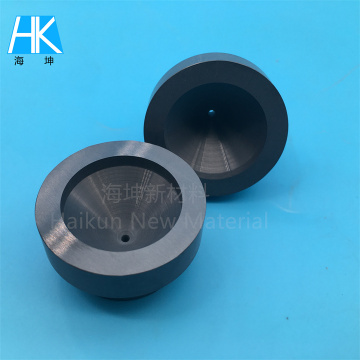

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords