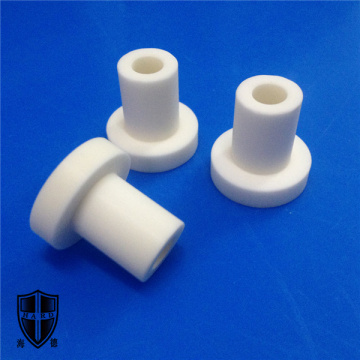

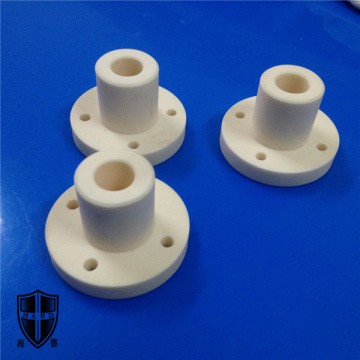

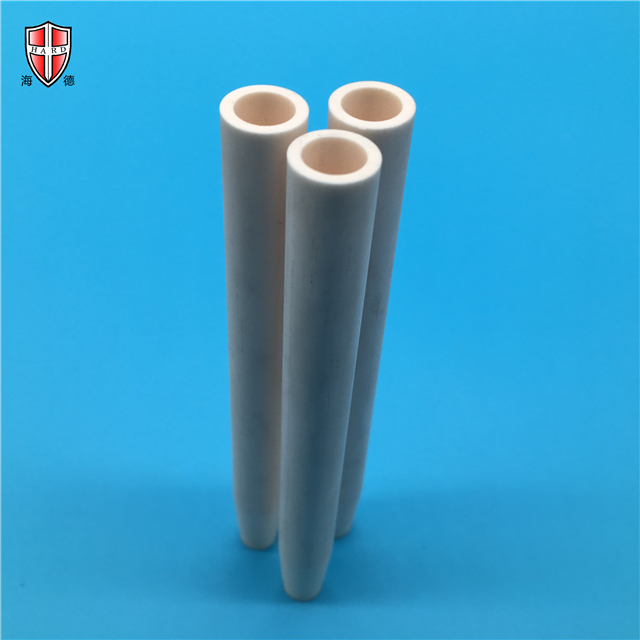

99% 99.5% alumina ceramic bush ferrule tube

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

99% 99.5% alumina ceramic bush ferrule tube

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The high temperature resistant and wear resistant ceramic coating is based on an inorganic binder and is combined with a light, hollow and loose ceramic microbead to form an inorganic coating film, which is blocked by an air microporous layer and a reflective layer having a low thermal conductivity. The heat energy transfer effectively suppresses the radiation heat transfer and convective heat transfer. In the high temperature environment, the sensitivity of the coating film to water is reduced. The silicon-oxygen bond of the high temperature resistant wear-resistant ceramic coating forms a network with higher hardness in the organic polymer. The structure, which increases the degree of organic film and temperature resistance, the two complement each other, forming a composite coating film with excellent performance, thereby achieving the purpose of lowering the heat balance temperature of the coated surface, and the heat insulation effect is remarkable. In the high temperature flue, the exhaust pipe is painted with high temperature resistant paint, the construction thickness is 3 mm, 800 degree burning and solidification, which achieves the function of thermal insulation and heat, and is beneficial to the emission of flue gas, reducing the generation of condensed water and avoiding unnecessary The pipe is corroded.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords