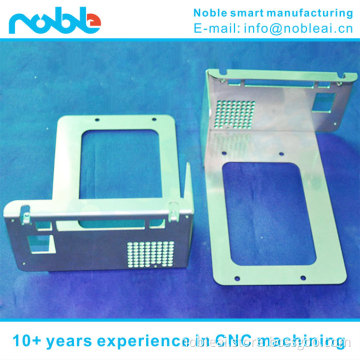

aluminum alloy intelligent wheelchair parts CNC machining quotation

- Payment Type:

- T/T, Paypal

- Incoterm:

- FOB, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, EXPRESS

- Port:

- SHENZHEN

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | CHINA |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Air,EXPRESS |

| Port: | SHENZHEN |

Product Description

Product Description

Project Quick details

Parts applications: Connecting piece

Material: Aluminum alloy, etc.

Manufacturing Process: 5-axis CNC machining

Finish Treatment: Sand blast and Anodic Oxidation

Difficulties & Highlights: It has high accuracy requirements and difficult to machine in Special-shaped

Size: Customer`s 3D/2D drawing

Brand name: Noble

Palace of origin: Shenzhen, China (mainland)

Intelligent Wheelchair is a robot that will assist severely disabled people deal with daily living activities. Unlike any of the existing wheelchairs, the proposed Intelligent Wheelchair can maximize the independent mobility for many types of disabilities in any circumstances. One of the most sophisticated features of the proposed Intelligent Wheelchair is that disabled people can interact with the Intelligent Wheelchair through intelligence and the slightest head movement. The robotic arms will be integrated with the Intelligent Wheelchair to enable various daily living activities to be performed independently, reducing the burden on caregivers and boosting spirits of Quads, and their loved ones alike.

Goals:

(1) Human-chair Interactions

(2) Robotic Arm Assistant (RAA)

(3) Autonomous Chair navigation

(4) Retractable Roof & Heads-up Display (RR & HD)

The sandblasting is the power of compressed air, then form a high-speed jet beam to jet the material-spraying on the surface of the parts to make the appearance or shape of the parts change.

Due to the abrasive corroding and cutting impact on the surface of the parts, then it has cleanliness and different roughness and the mechanical properties are improved. So, the fatigue resistance improves, the adhesion between it and the coating increases, the durability of the coating lengthens, and also it benefits for the decoration of the paint.

Our Equipment

We are familiar with the CNC machining core technology and we integrate other upstream and downstream resources in our industrial chain to offer the best service for our customer.

We have 4 five-axis CNC, more than 30 high-speed CNC machining centers, CNC lathes, CNC carved machines, in total we have more than 50 machining equipment.

Quality control:

We will provide all documents as you need such as inspection report, material report, etc. To meet your quality requirements of products and parts.

After-sale service:

If the parts have any quality problems when you got them, no matter it happened when we made them or caused by the delivery, we will try best to help you to solve the problems and take our part of responsibility, so you will be free from worries.

Parts applications: Connecting piece

Material: Aluminum alloy, etc.

Manufacturing Process: 5-axis CNC machining

Finish Treatment: Sand blast and Anodic Oxidation

Difficulties & Highlights: It has high accuracy requirements and difficult to machine in Special-shaped

Size: Customer`s 3D/2D drawing

Brand name: Noble

Palace of origin: Shenzhen, China (mainland)

Intelligent Wheelchair is a robot that will assist severely disabled people deal with daily living activities. Unlike any of the existing wheelchairs, the proposed Intelligent Wheelchair can maximize the independent mobility for many types of disabilities in any circumstances. One of the most sophisticated features of the proposed Intelligent Wheelchair is that disabled people can interact with the Intelligent Wheelchair through intelligence and the slightest head movement. The robotic arms will be integrated with the Intelligent Wheelchair to enable various daily living activities to be performed independently, reducing the burden on caregivers and boosting spirits of Quads, and their loved ones alike.

Goals:

(1) Human-chair Interactions

(2) Robotic Arm Assistant (RAA)

(3) Autonomous Chair navigation

(4) Retractable Roof & Heads-up Display (RR & HD)

What can we do?

Production process

The sandblasting is the power of compressed air, then form a high-speed jet beam to jet the material-spraying on the surface of the parts to make the appearance or shape of the parts change.

Due to the abrasive corroding and cutting impact on the surface of the parts, then it has cleanliness and different roughness and the mechanical properties are improved. So, the fatigue resistance improves, the adhesion between it and the coating increases, the durability of the coating lengthens, and also it benefits for the decoration of the paint.

Our Equipment

We are familiar with the CNC machining core technology and we integrate other upstream and downstream resources in our industrial chain to offer the best service for our customer.

We have 4 five-axis CNC, more than 30 high-speed CNC machining centers, CNC lathes, CNC carved machines, in total we have more than 50 machining equipment.

We provide the machining service of CNC milling, turning, engraving, cutting, tapping, drilling and so on.

Quality control:

We will provide all documents as you need such as inspection report, material report, etc. To meet your quality requirements of products and parts.

After-sale service:

If the parts have any quality problems when you got them, no matter it happened when we made them or caused by the delivery, we will try best to help you to solve the problems and take our part of responsibility, so you will be free from worries.

Related Keywords

Related Keywords

You May Also Like

You May Also Like