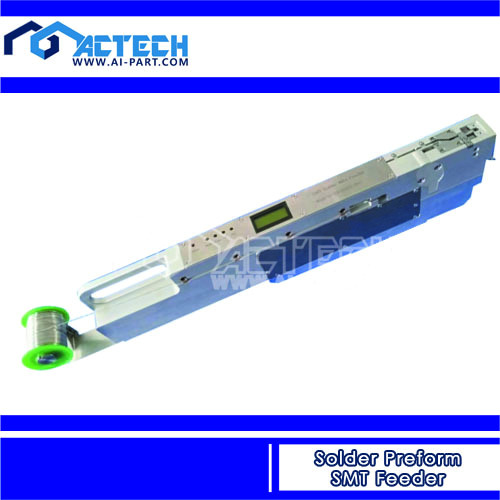

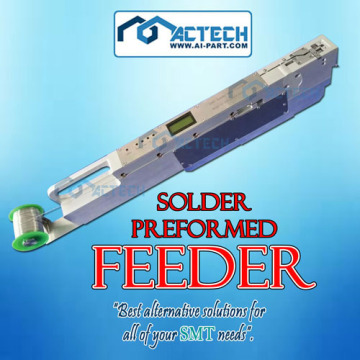

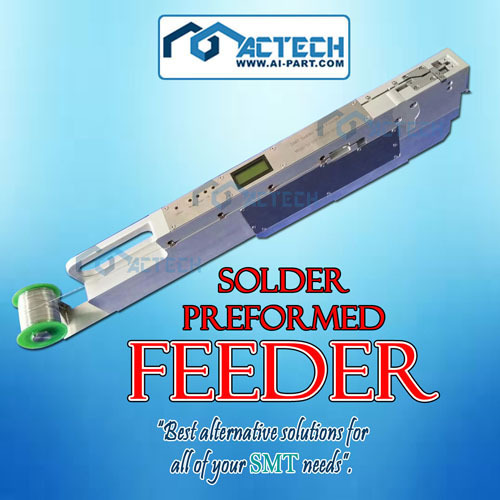

Automatic Solder Preform Feeder

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 3 Days

- Transportation:

- Ocean, Land, Air, UPS and Other

- Port:

- Shenzhen Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean,Land,Air,UPS and Other |

| Port: | Shenzhen Port |

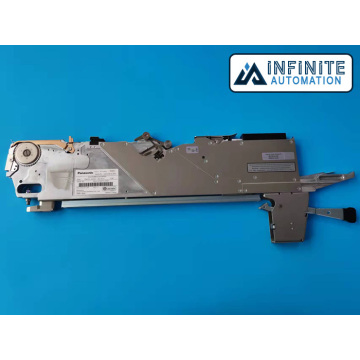

KDW has an innovative design to provide a cheaper solution for Solder Preform Feeder that are often used in SMT production process. KDW has designed an Electronic Feeder Unit with the ability to create solder preforms using regular solder thin wire. KDW Automatic Solder Preform Feeder can now be Used and passed machine compatibility testing with most of SMT pick and place machine brands. KDW Automatic Solder Preform Feeder is compatible with Juki, Samsung, Fuji NXT2, Fuji NXT3, Fuji XP141, Fuji XP143, Fuji XP143, Fuji XP242, Fuji XP243, Fuji XPF, Panasonic CM402, Panasonic NPM and Siemens D Series pick and place machines. We are constantly creating designs to Make the SMT Solder Preform Feeder compatible to all SMT machine brands and models. Contact us to find out more about the benefits you can get with the KDW Solder Preform Feeder.

The basic function of this Feeder is to flatten the solder thin/wire and produce solder plates. Flatten solder wire are cut into solder plates according to length settings.

The use of the solder plate is to add thickness to some components that requires more solder (3 pins transistors, USB jack pins, etc.) - PCB will still undergo normal solder paste printing process and this solder plates will be mounted by pick and place Machines (a little off-set to the pad with solder paste on it). Then component will also be mounted on the pad.

The purpose of the feeder is to lessen the cost by taking out costings on component reels or other solutions that is currently implemented in SMT production process.

In many SMT assembly designs, there is a need to apply a larger solder volume in certain locations. Traditional co-planar stenciling often will not deliver the solder volume required. The alternatives, like dispensing or manual soldering, are not expensive enough, time consuming And sometimes can cause damage to components on PCB.

In such situations, many customers are using solder preforms, which is probably the best way to add solder thickness. However, preforms in tape and reel packaging are expensive and it affects the cost of production.

With the new Automatic Solder Preformed Feeder, we offer an elegant and cost effective solution, making the whole process simple and easy to handle. A standard solder wire reel is used instead, the feeder automatically produced the preforms and feeds them to be picked and placed On assembly. Different diameter solder wire can be used for different preform sizes.

|

WIRE DIAMETER |

PREFORM SIZE |

|

1.2 mm |

( 1206) 3.2 x 1.6 mm |

|

0.8 mm |

(0805) 2.0 x 1.25 mm |

|

0.6 mm |

(0603) 1.6 x 0.8 mm |

Features and Benefits of using Automatic Solder Preform Feeder:

1. High efficiency, 0.25 sec. / preform

2. Small width (36 mm.), light weight (3.5 kg.)

3. Pure electric, low noise

4. Can be customize to all mounter machine brand and type

5. Apply to any location with particular need for additional solder

6. Good solder ability, no-clean, environment friendly, convenient

7. Reduce labor cost, improve quality

8. Use of different wire diameter to create preforms of different size

9. Working with any brand of solder wire

Specification:

Dimension: 500 x 36 x 100 (mm.)

Weight: 3.5 kg.

Automatic Solder Preform Feeder Images:

Related Keywords