Vacuum Plating And Water Plating

- Payment Type:

- T/T

- Min. Order:

- 10 Bag/Bags

- Min. Order:

- 10 Bag/Bags

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- SHENZHEN, Guangzhou, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | China |

| Supply Ability: | good |

| Payment Type: | T/T |

| Transportation: | Ocean,Land,Air |

| Port: | SHENZHEN,Guangzhou,Shanghai |

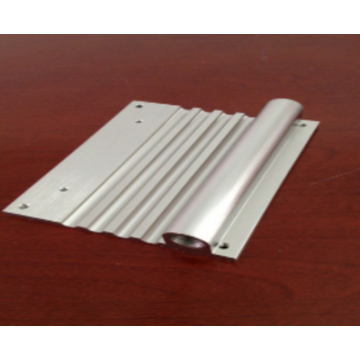

The company is divided into electronic and electroplating. The electronic department mainly produces various kinds of fuse. Plating department is mainly valet processing: plastic water plating, high demand of plastic without nickel plating, plastic vacuum plating, hardware electrical and gold, silver, platinum and other precious metal plating processing, plastic resin plating and barrel plating of plastic processing. We have 30, 000 square meters of modern production facilities, imported fully automatic electroplating production line, experienced production, r&d and management of more than 30 people. The quality management is strictly according to ISO9001,2000 quality system, and obtains the IS014001 environment demonstration. Equipped with advanced Japanese imported film thickness tester, salt mist tester, constant temperature/constant temperature tester, hardness tester, cyke digital technology and shadow tester, etc. The company is a large number of domestic and foreign big, medium customers and **500 strong brand cooperation and long-term suppliers. Our plating department processing projects are: one, plastic, ABS electroplating water, plastic water has three fully automatic electroplating production line, with high quality trivalent chrome, black collaterals, pearl chromium, light dark gun color, 24 k gold, imitation gold, thick nickel wire drawing. At the same time, the development of high demand plastic nickel plating technology has been developed, which has become a long-term stable supplier for big brands of mobile phones and headphone accessories. We have specialized electroplating production line, which can be processed in high difficulty and high difficulty. Main products are: automotive parts plating, car flag electroplating, 2 meters of less than 4 s large logo plastic electroplating, China open car, decoration, wheel, shake handshandle outside accessories plating. Automobile audio accessories perfume and other interior accessories plastic plating. Plating of wine fittings, electrical accessories and plastic parts for game machines. Electric knobs, large parts of electric shell plating and wire seal oil, electric shell decoration plating, key plating. All kinds of border plating and decorative strip plating. Digital products, mobile phone products, digital camera, PC+ABS double color plating. Plastic ABS rolling process, ** mirror plastic electroplating, furniture fittings electroplating, perfume bottle cap plastic water plating. 2. Hardware electroplating is: electronic product shell, electrical hardware accessories, digital products and bags and shoes accessories plating. All kinds of fan mesh cover plating. There are environmental chrome, gun color, pearl color, imitation gold, 24K genuine gold, etc. It also processes precious metals, gold, silver and platinum. High conductivity products, jewelry plating. 3. Plastic vacuum electroplating process. Automatic electroplating production line, with UV electroplating as the main, plastic magnetic control spatter, semi-permeation plating, phantom color UV plating. The electroplating color can be controlled according to the requirements of the customer, the main products are the hand case, sheath, electric shell and decorative parts, electronic keys, perfume bottle, reflective cup electroplating, electronic nameplate and other products.

Related Keywords