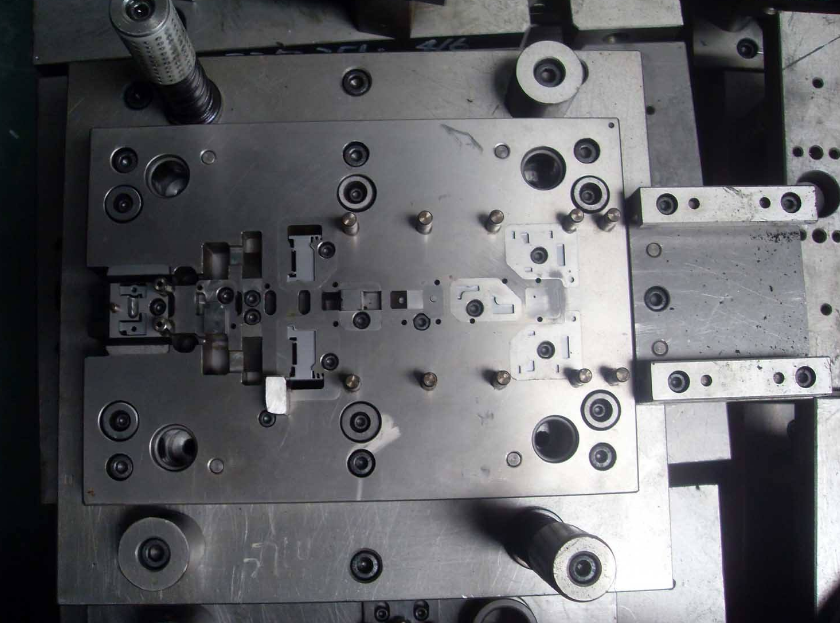

Metal stamping die kc105

- Payment Type:

- T/T

- Min. Order:

- 10 Bag/Bags

- Min. Order:

- 10 Bag/Bags

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- SHENZHEN, Guangzhou, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | China |

| Supply Ability: | good |

| Payment Type: | T/T |

| Transportation: | Ocean,Land,Air |

| Port: | SHENZHEN,Guangzhou,Shanghai |

Metal stamping die kc105

When I conduct conferences, it isn't unusual to have one or two attendees who are new to the stamping die and pressworking world. Some are young new hires trying to learn about stamping, and others are individuals who have been transferred from a different department and thrown to the wolves in the stamping department.

This article is the first in a series intended to introduce beginner toolmakers, die maintenance technicians, engineers, and press technicians to stamping. The series will define a die as well as a stamping operation. It will also discuss cutting and forming operations, components and functions, and different methods used to stamp parts.

What Is a Stamping Die?

A stamping die is a special, one-of-a-kind precision tool that cuts and forms sheet metal into a desired shape or profile. The die's cutting and forming sections typically are made from special types of hardenable steel called tool steel. Dies also can contain cutting and forming sections made from carbide or various other hard, wear-resistant materials.

Stamping is a cold-forming operation, which means that no heat is introduced into the die or the sheet material intentionally. However, because heat is generated from friction during the cutting and forming process, stamped parts often exit the dies very hot.

Typical Cut Edge of a Stamped Part

Dies range in size from those used to make microelectronics, which can fit in the palm of your hand, to those that are 20 ft. square and 10 ft. thick that are used to make entire automobile body sides.

Company's leading product categories: hardware and plastic wire drawing, sandblasting, polishing processing, to undertake professional aluminum oxide, two oxygen, passivation, pick light, hardware rolled a gold-plated, silver, nickel, chromium, zinc, etc.

The company has a number of professional engineering designers, advanced production equipment and reliable production capacity; We advocate advanced enterprise culture, the pursuit of advanced management concept, management ideas and talented person idea, set up the harmonious unity of the morality of diligent, honest and trustworthy, adhere to strengthen enterprise two civilization construction, increase staff cohesion, the outside good enterprise image, enhance the core competitiveness of the company.

Related Keywords