Audits Pre-shipment Inspection Marble

Your message must be between 20 to 2000 characters

Contact Now

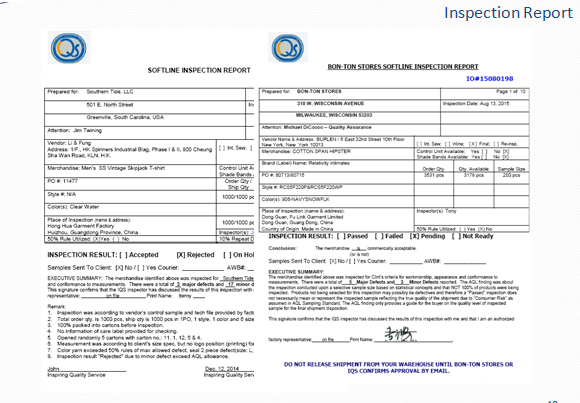

This is IQS QC service, provides the third-party quality control service. An all-inclusives service including examining cargo, factory evaluation and container loading etc.

Product inspections allow to check production at any stage, especially before client sends out the balance payment to suppliers. By performing a product inspection, you ensure that there would be no surprise at destination when opening the boxes.

The inspector would check all your requirements and the specificities of your product, and give a status of your production in the inspection report. The goal is to catch issues and have them corrected, reworked or replaced by factory before shipment as there is no return policy with Asian suppliers, even less so in China. So it is fundamental to check whether the production is acceptable before it leaves the factory. Quality Control Partners Ltd. offers all types of product inspection before shipment.

- IPC: Initial Production Checking, this way is inspection of

raw materials, components prior to the commencement of production, check

products' status is match as client's specification, function checking and

on-site testing to make sure to find issues before mass productions. this will

be help to client to find quality issue as early as possible.

- DUPRO: During

Production Inspection, this way is inspection when 20%-80%

shipment quantity is ready, to check all kinds of issue including packing,

marking, quantity, production quality, function, on-site testing, this DUPRO is

similar to finial random inspection process but this way still can find quality

issue before shipment are completely finished.

- FRI: Final Random Inspection , this way is

inspection based on all shipment products are finished and at least 80% were

packed into out cartons, this inspection will be most representative for the

shipment, inspector check all details on packing, marking, function, visual

quality and function checking, on-site testing, etc, and all special

requirements from the clients.

-PM: Product Monitoring,

this is way that client request Top Inspection send engineers or inspectors to

stay at factory, monitor and check factory's production line, check and solve

quality problem, then with daily report to clients.

- CLS: Container Loading

Supervision, this way is inspection that make sure client's

shipment is correct, safe and enough shipment quantity productions to be

shipped. before loading, inspector need to check the empty containers are

clean, well conditions, no bad smell, no hole, correct container number, well

locking bars, to make sure containers are safe and suitable to loading. also

will check correct productions and correct shipment marking, packing method.

during loading, inspector monitor whole loading process, no damage cartons be

loaded into containers. make sure correct productions and enough quantity

cartons were loaded into containers.

IQS Inspection use standard sampling level and AQL, based on ISO 2859, ANSI/ASQ Standard Z1.4-2003, inspector select randomly samples from shipment product, exactly check visual quality, function checking, production marking and packing, on-site testing, and all necessary special request from the clients.

Related Keywords