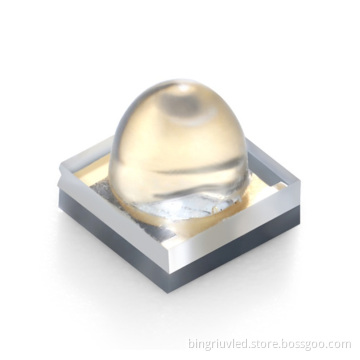

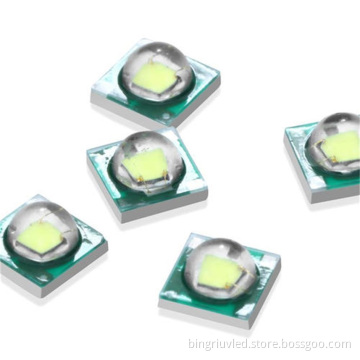

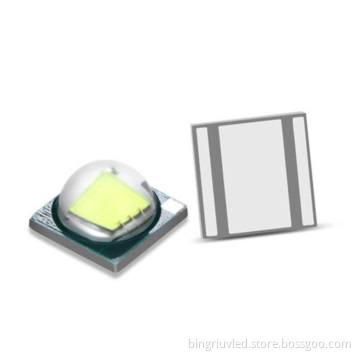

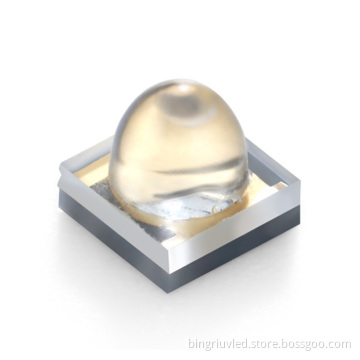

3535 LED Luminous Lamp Beads, Super Bright

- Transportation:

- Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO9001;IATF16949 |

| Transportation: | Air |

3535 LED Luminous Lamp Beads, Super Bright

We are the chip of the brand manufacturer, the chip of the lamp bead is just like the heart of the human body. Our chip has the characteristics of high brightness, strong anti-static ability, strong anti-fall ability, good consistency, and not easy to die. We have advanced equipment, high-efficiency work, fully automatic optical devices and image preview processing chips.

- Features

* Emitted Color: UVC

* Lens Appearance: Clean quartz lens

* Dimensions:3.5*3.5mm* Power:25-30mW

* Optical Angle:60 degree

* Current:150mA

* Voltage:6.5V

* Wavelengths: 270-280nm

- Applications

1.Sterilize

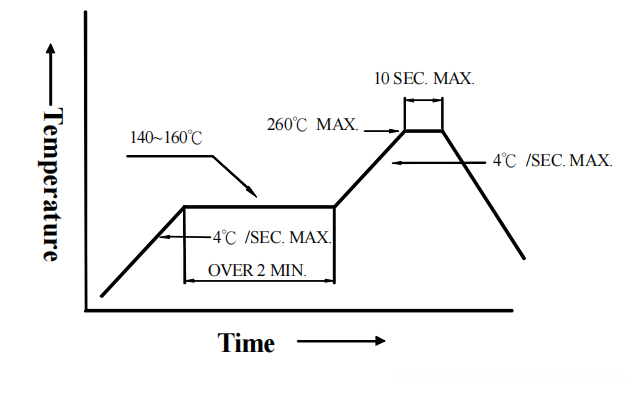

- Soldering:

Gradual Cooling (Avoid quenching)

- Storage

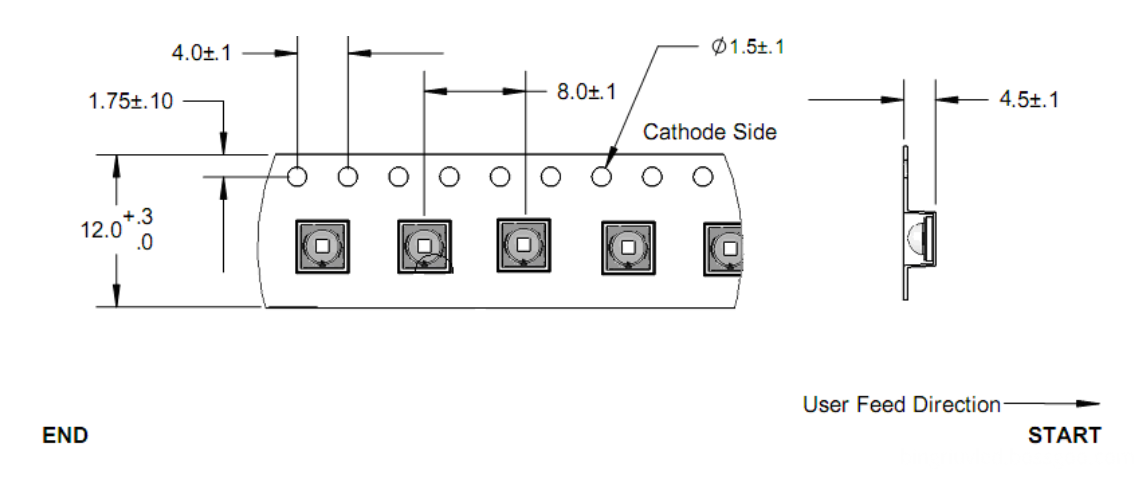

- Tapping and packaging specifications (Units: mm)

* Widely used in surface sterilization,air sterilization,water sterilization,and has a high usage rate in biomedicine.

Related Keywords