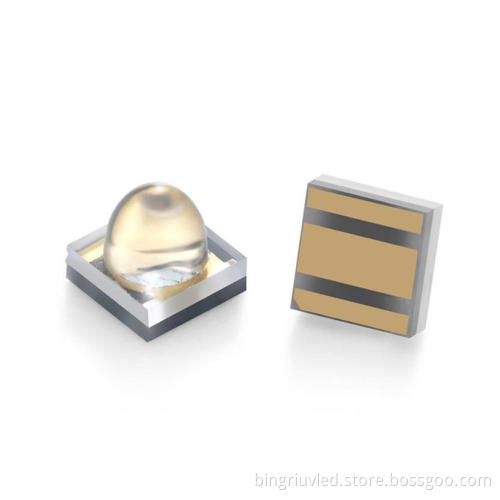

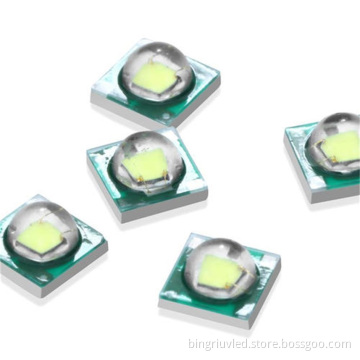

3535 Alumina Ceramic Substrate Lights High Power

- Transportation:

- Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO9001;IATF16949 |

| Transportation: | Air |

3535 Alumina Ceramic Substrate Lights High Power

We produce high-performance, high-reliability power LEDs, a variety of specifications are available, suitable for different scenarios, different currents, you can find what you need in our shop, or you can consult with us, we will best Service brought to you. We are a professional LED lamp bead looking for a lighting manufacturer, with a complete range of lamps and a reasonable price. We have strong strength, high credit, guarantee the quality of our products, and win the trust of our customers with our diversified operating characteristics and the principle of small profits but quick turnover.

- Features

* Emitted Color: UVC

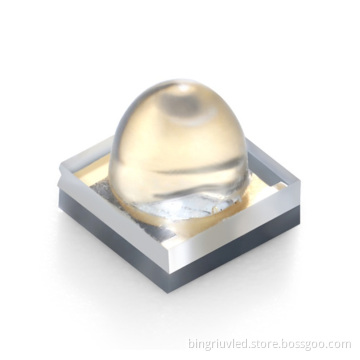

* Lens Appearance: Clean quartz lens

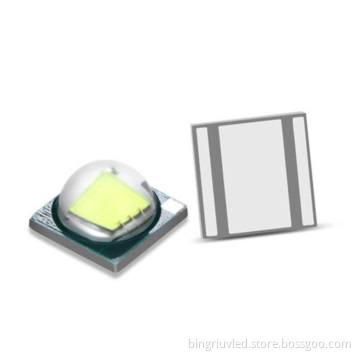

* Dimensions:3.5*3.5mm* Power:25-30mW

* Optical Angle:60 degree

* Current:150mA

* Voltage:6.5V

* Wavelengths: 270-280nm

- Applications

1.Sterilize

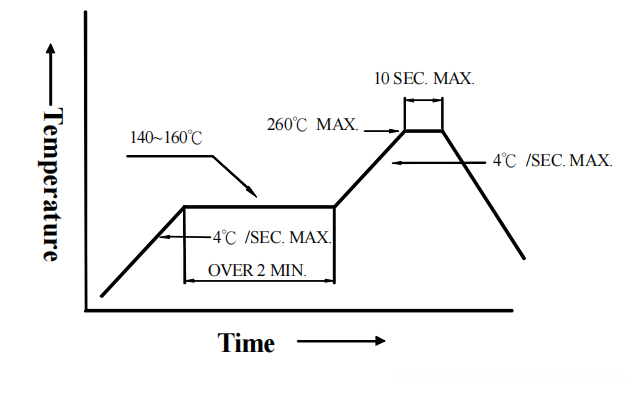

- Soldering:

Gradual Cooling (Avoid quenching)

- Storage

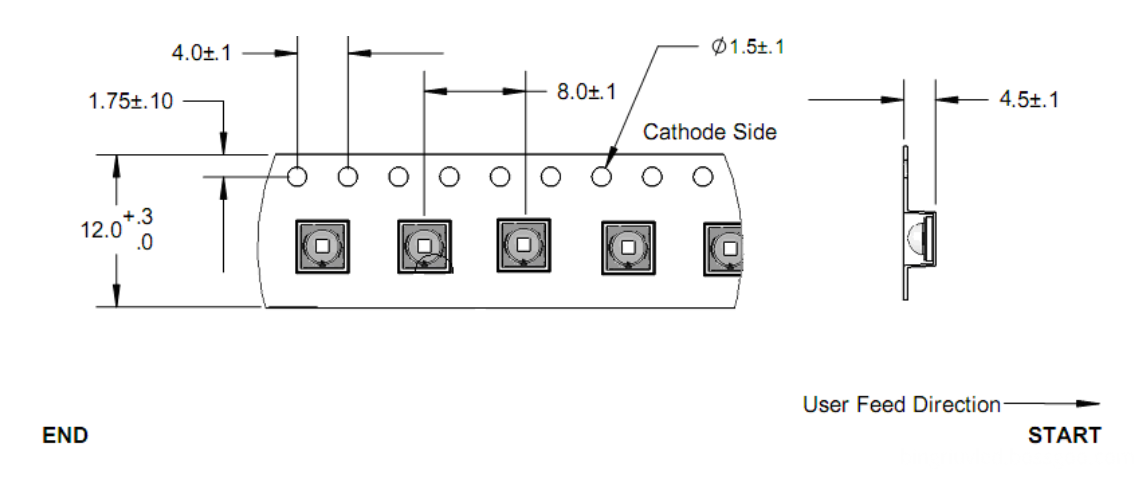

- Tapping and packaging specifications (Units: mm)

* Widely used in surface sterilization,air sterilization,water sterilization,and has a high usage rate in biomedicine.

Related Keywords