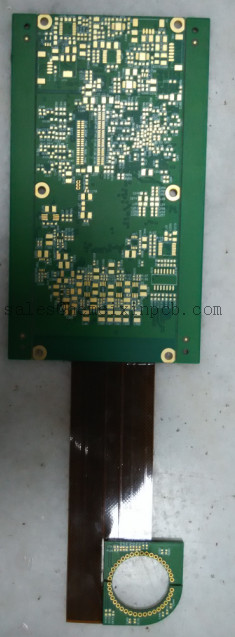

rigid flex PCB Prototype fabrication

Your message must be between 20 to 2000 characters

Contact NowDuring the Rigid Flexible PCB design process, certain considerations must be taken into account for final product size variations. In the manufacture of rigid flex boards, the flexible polyimide core will shrink once the bonded copper foil is etched away. This variation must be accounted for in the design process.

Consumers' escalating demand for more features in their small and mobile electronics products, such as PDAs and cell phones, is driving a need for smaller feature sizes, process geometries, and pc boards. For engineers dealing with these desires, the need for HDI (high-density-interconnect) technology has become a reality. HemeixinPCB describes HDI technology as a process that lets you produce a pc-board with through-hole, blind, or buried vias of less than 0.006 in. in diameter without using conventional drilling technology. Users of HDI technology must be able not only to assess and implement next-generation technology, but also to understand its boundaries in terms of layer stack up, via and microvia formation, feature size, and the primary differences between it and traditional pc-board technologies.

Related Keywords